Electrical measurement based four-point type nondestructive test probe with adaptive adjustment

A self-adaptive adjustment and non-destructive testing technology, applied in the direction of material impedance, etc., can solve problems such as difficult to use production links, affecting the subsequent use of the tested material, etc., to achieve the effect of improving measurement accuracy, fast handheld measurement, and improving use flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

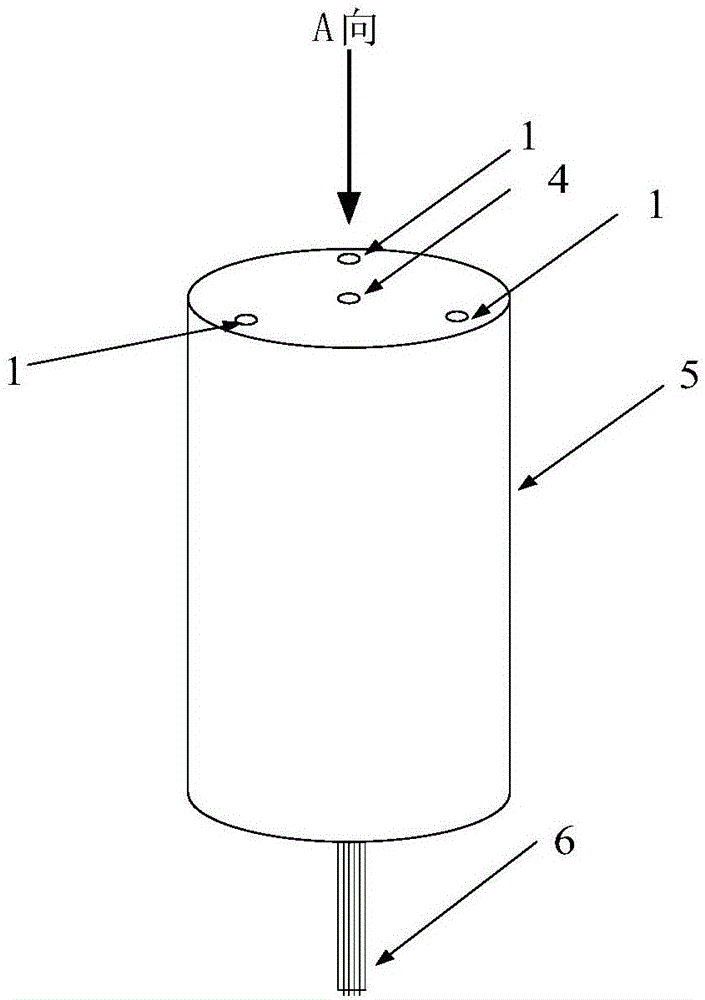

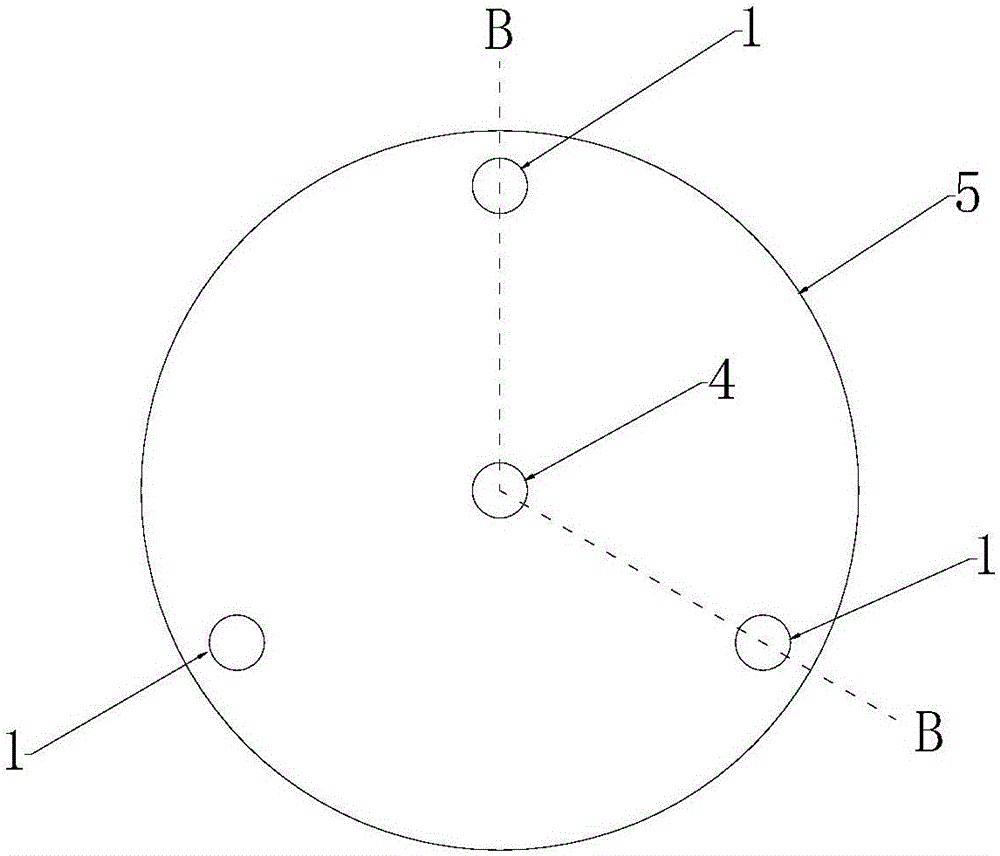

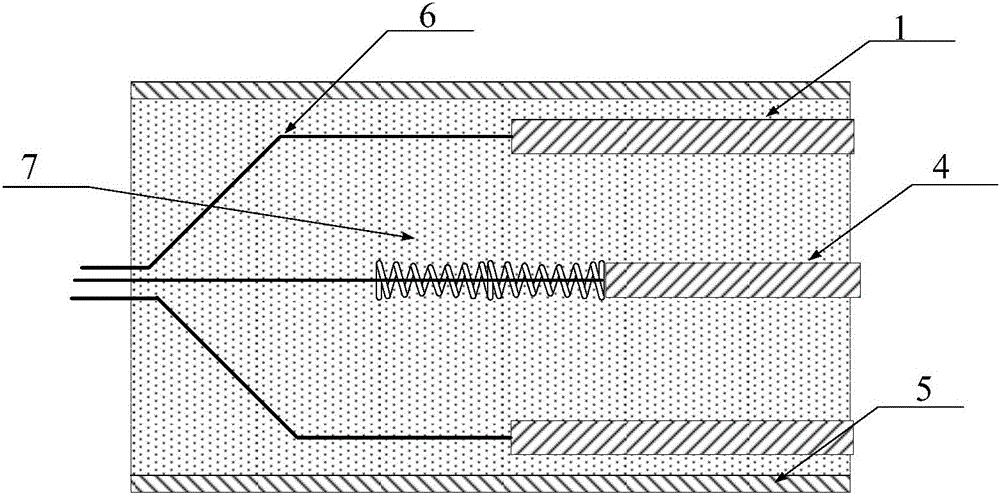

[0026] In conjunction with the accompanying drawings, the structure of the four-point self-adaptive adjustment non-destructive testing probe based on electrical measurement of the present invention is further described:

[0027] The four-point self-adaptive adjustment nondestructive testing probe based on electrical measurement of the present invention includes three identical fixed electrodes 1, one movable electrode 4, housing 5, wire 6, filling material 7, three identical fixed electrodes The electrodes 1 are evenly distributed in the circumferential direction of the housing 5, and are used as measuring electrodes; the movable electrodes 4 are located in the center of the housing 5, and are used as excitation electrodes, and the four electrodes are insulated and isolated by a filling material 7, and the four electrodes Connect with the external display instrument through wire 6. The movable electrode 4 is provided with a spring inside, so that the length of the movable elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com