A kind of anti-blue light film structure and anti-blue light lens and application thereof

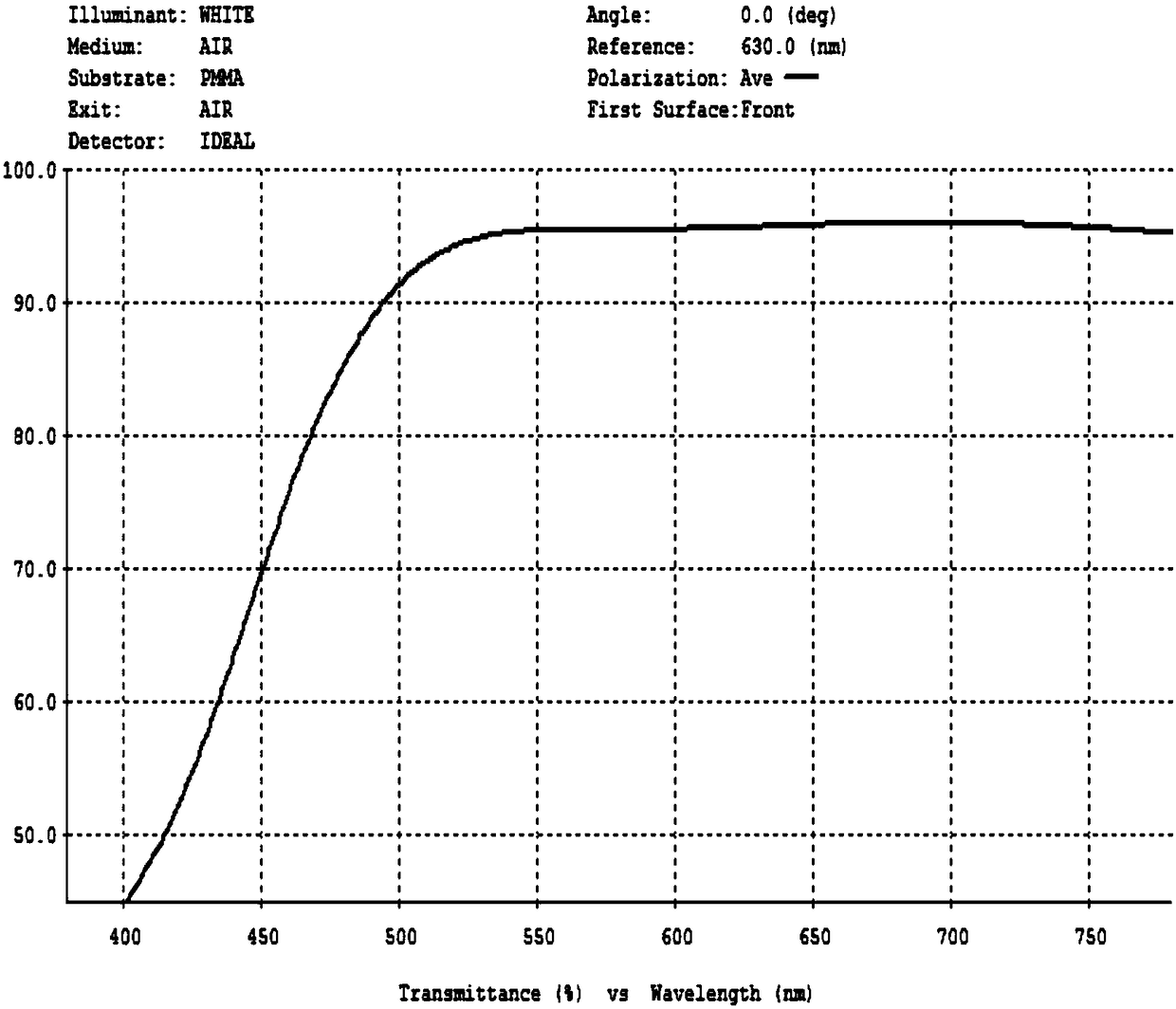

A film structure, anti-blue light technology, applied in the field of optical materials, can solve the problems of macular degeneration, health risks of optical lenses, etc., to achieve the effect of solving damage, reducing blue light transmission, and increasing film strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

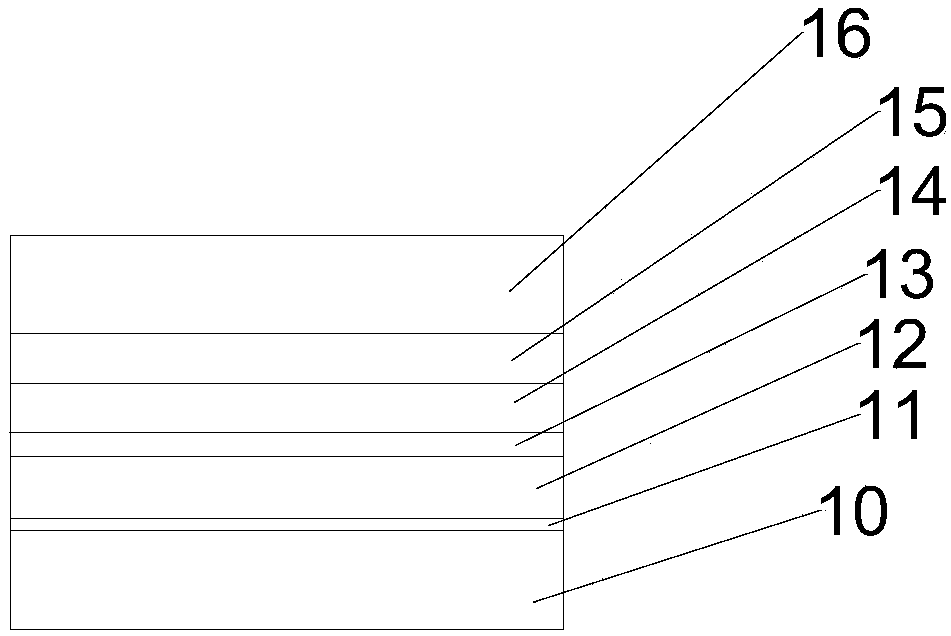

[0024] figure 1 It is a structural schematic diagram of the anti-blue light lens of the present invention. Such as figure 1 As shown, the anti-blue light lens of the present invention mainly includes a base 10 and an anti-blue light film structure coated on the base. Because the actual thickness of membrane structure is very little, so the present invention figure 1 It is a schematic diagram and does not represent the actual thickness relationship between the film layer and the substrate.

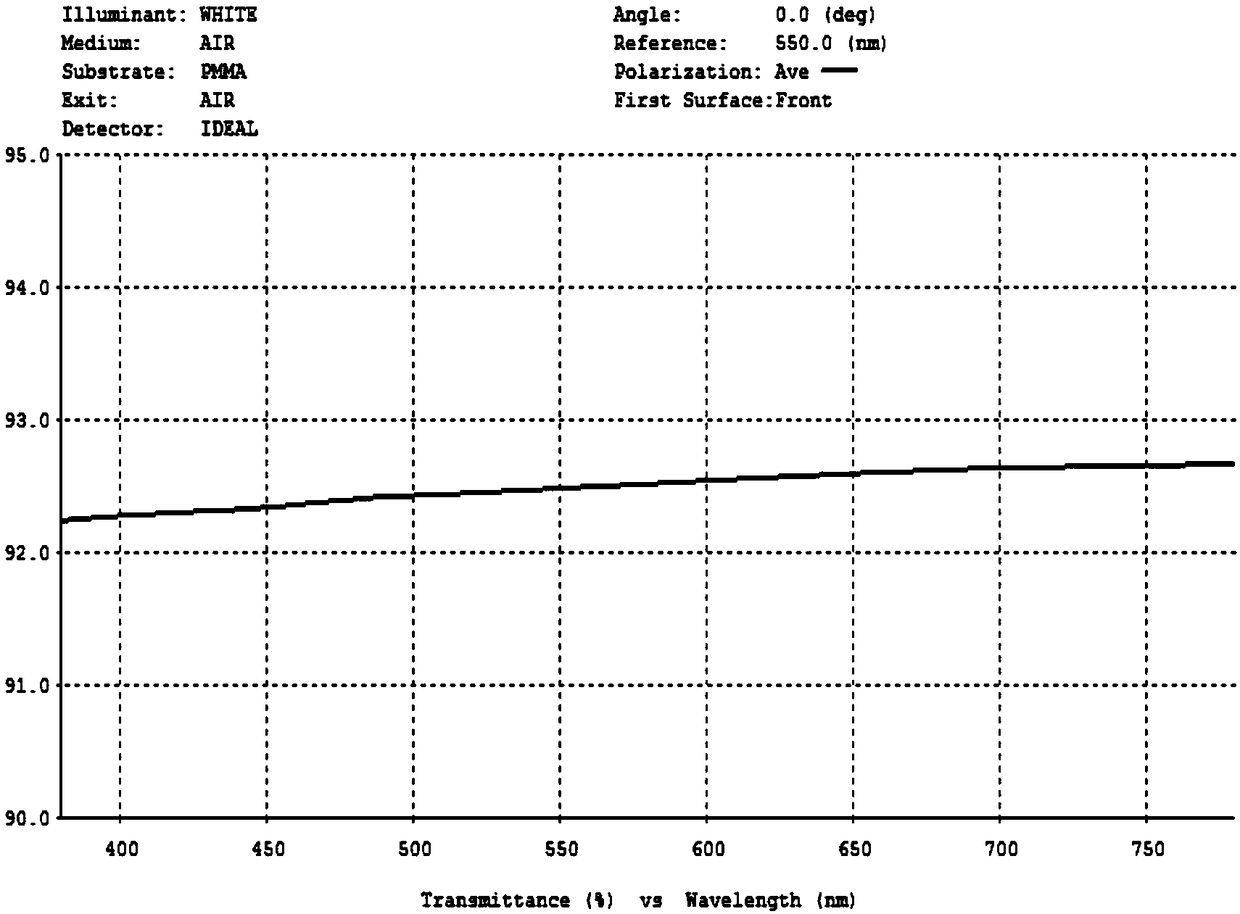

[0025] Among them, PMMA (polymethyl methacrylate) is selected as the base, which is a kind of optical plastic material widely used at present, commonly known as plexiglass. The penetration is as high as 92% and has very low birefringence.

[0026] Among them, the anti-blue light film structure is composed of six layers of high and low refractive index materials. From the inside to the outside, they are: the first layer of high refractive index film 11, the second layer of low refractive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com