A central feeding device and method for silica particle deposition

A silicon dioxide and feeding device technology, which is applied in the direction of measuring devices, general control systems, sequence/logic controller program control, etc., can solve the problems of low utilization rate of land resources, frequent operations by operators, and heavy physical exertion, etc. problems, to achieve the effect of improving feeding quality and work efficiency, reducing the risk of human error, and high-quality and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

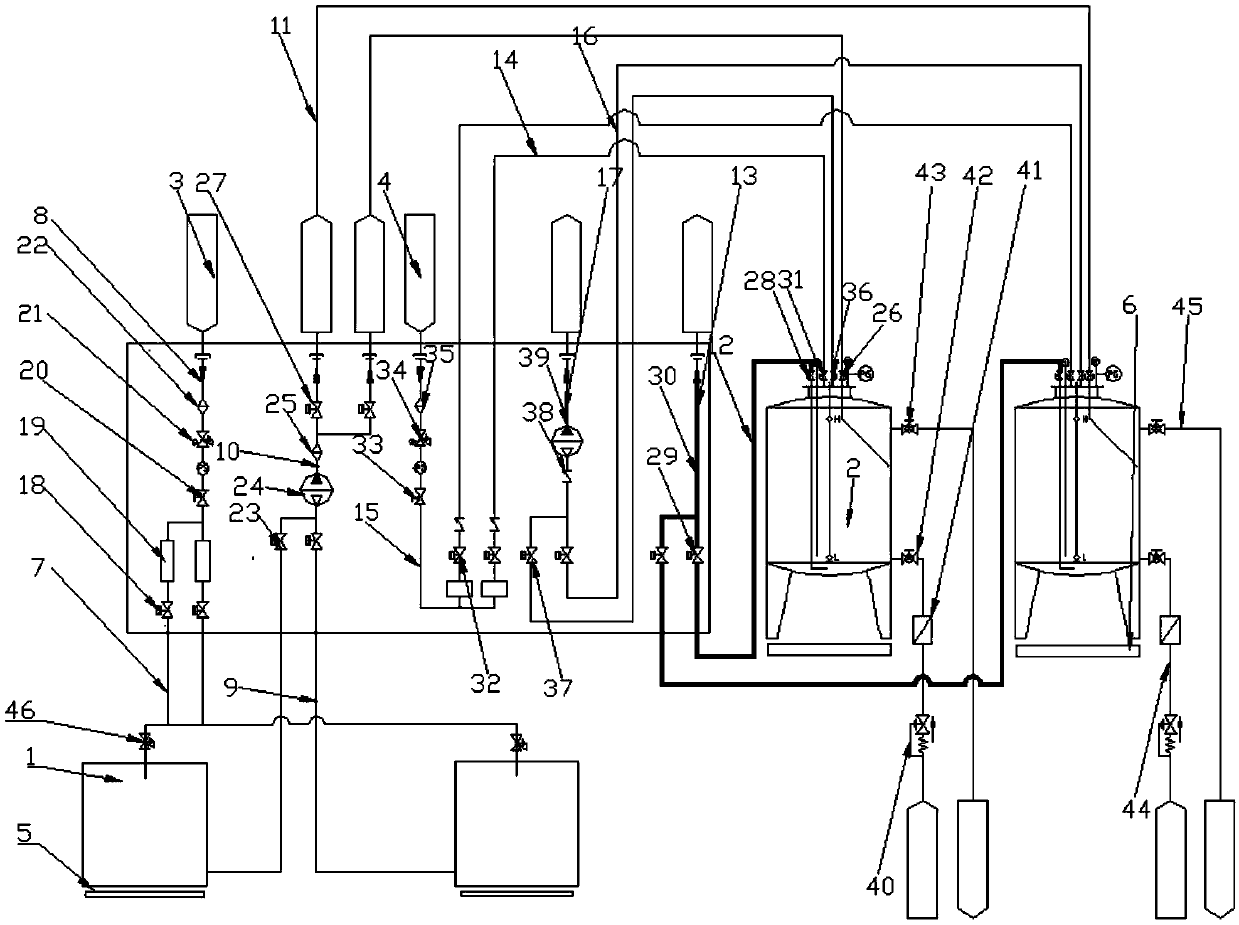

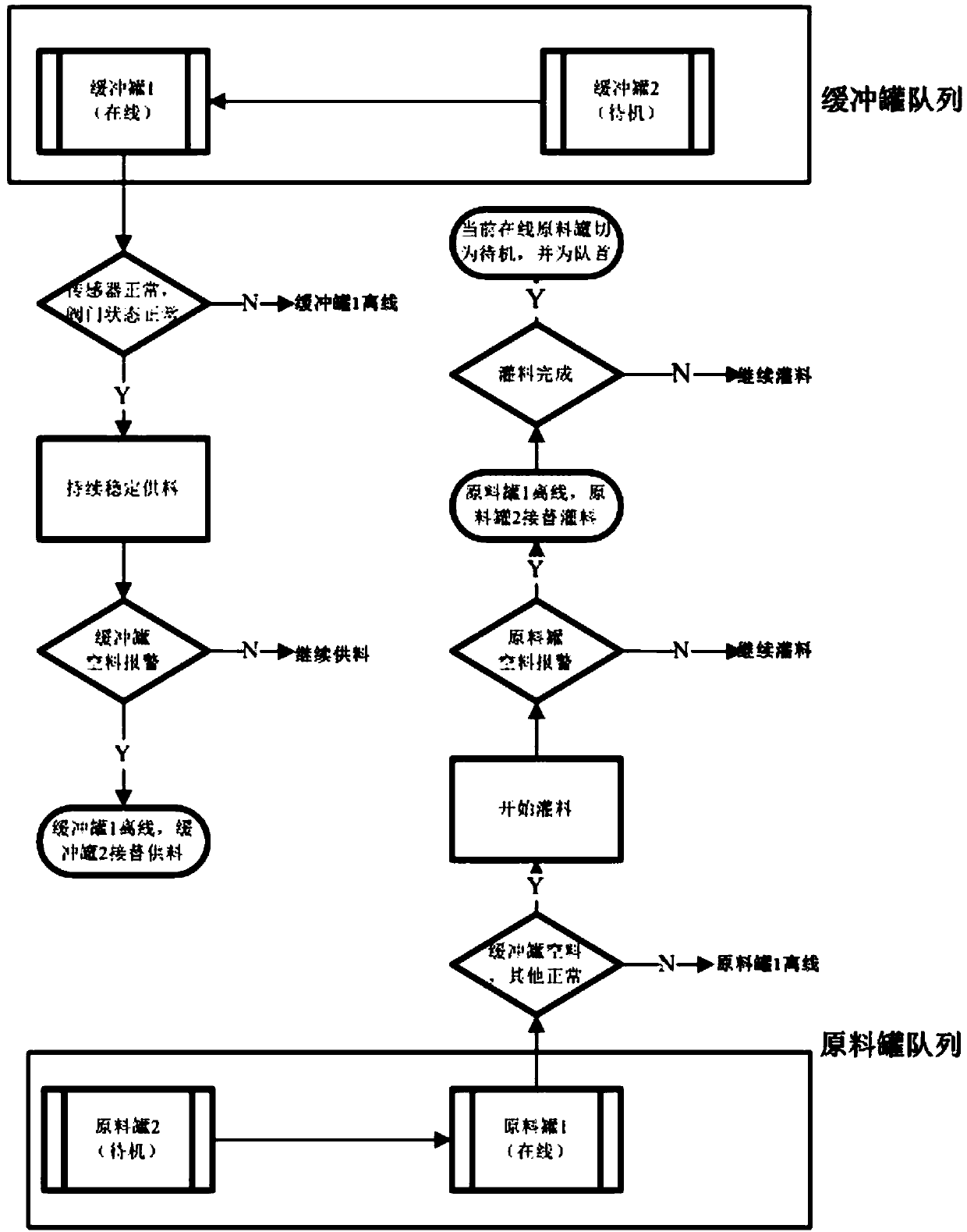

[0024] Such as figure 1As shown, a central feeding device for the deposition of silica particles includes several raw material tanks 1, several buffer tanks 2, stabilized gas tanks 3 and pressure gas tanks 4, and several raw material tanks are equipped with The air supply port and the filling port, the air supply port is connected to one end of the air supply main pipe 8 through the air supply branch pipe 7, the stabilized air tank is connected to the other end of the air supply main pipe, and the filling port is connected to the filling main pipe 10 through the filling pipe 9 , Several buffer tanks are provided with feed inlet, feed inlet, air inlet and exhaust outlet, the feed inlet is connected with the filling main pipe through the feed sub-pipe 11, and the feed port is connected with the feed mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com