Memory and manufacturing method thereof

A manufacturing method and technology of memory elements, which are applied in the fields of electric solid state devices, semiconductor devices, electrical components, etc., can solve the problems of limiting the memory density of memory elements, reducing process margins, insufficient engraving depth, etc., and achieving improved process margins, The effect of large etching profile and good work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

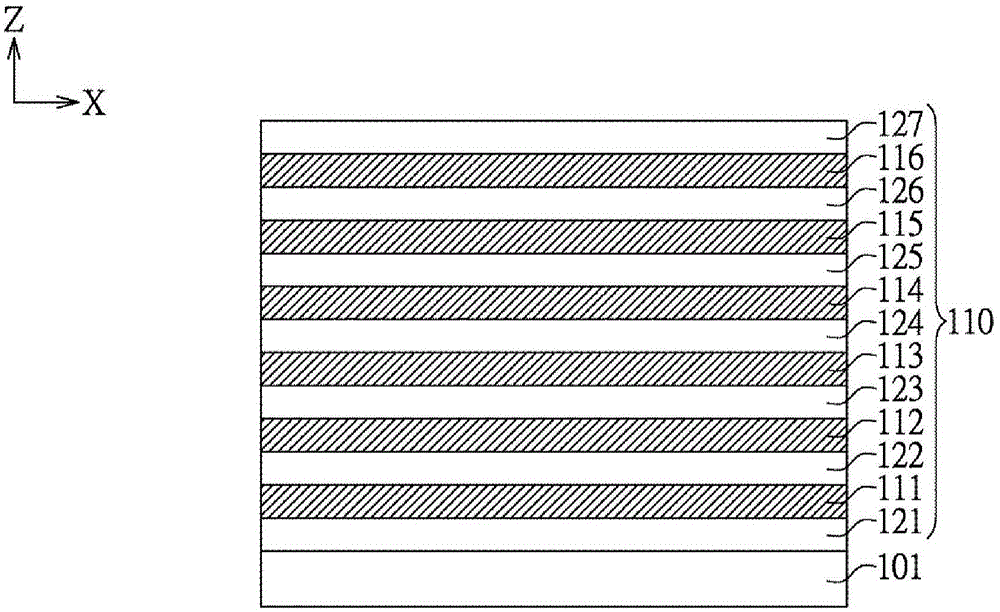

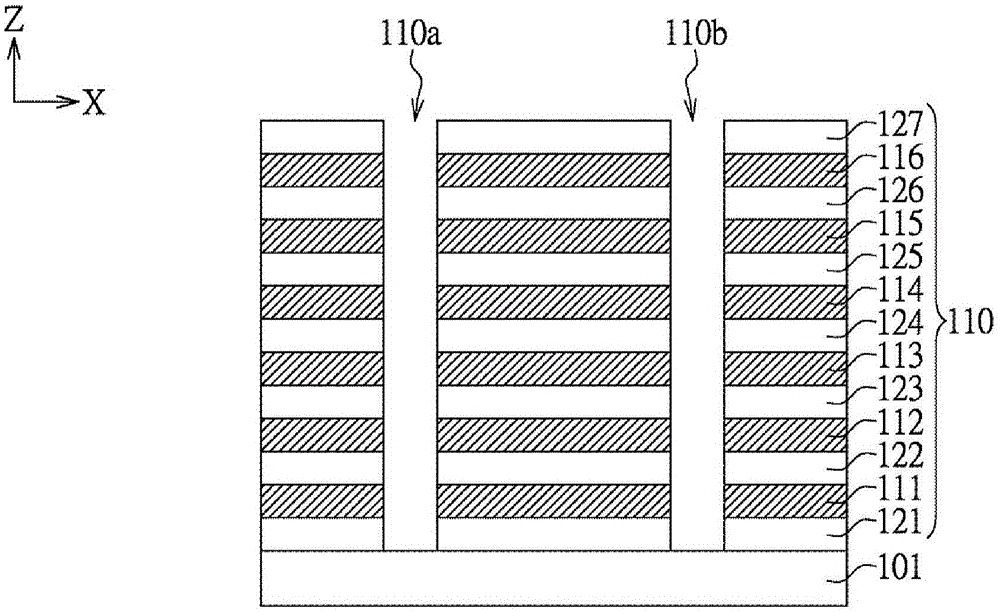

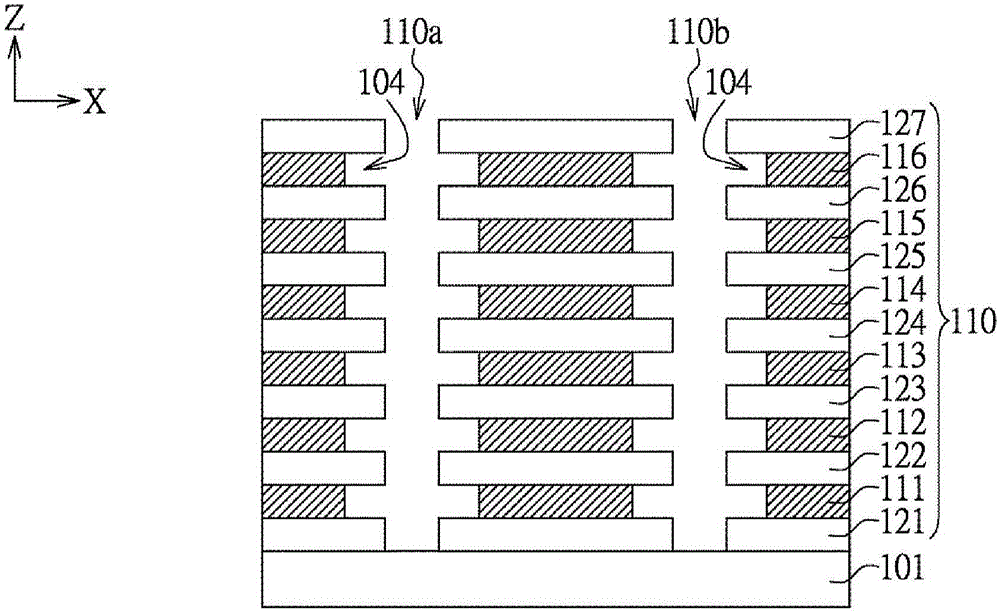

[0061] The present invention provides a semiconductor element and a manufacturing method thereof, which can improve the reliability problem of memory elements affecting the reliability of writing / erasing operations due to corner effects. In order to make the above-mentioned embodiments of the present invention and other objects, features and advantages easier to understand, an embedded memory element with a memory unit, a logic unit and a high-voltage unit and its manufacturing method are specifically cited below as a preferred embodiment, and in conjunction with Attached drawings describe in detail.

[0062] However, it must be noted that these specific implementation cases and methods are not intended to limit the present invention. The invention can still be implemented with other features, elements, methods and parameters. The proposal of the preferred embodiment is only used to illustrate the technical characteristics of the present invention, and is not used to limit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com