Air-cooled permanent magnet eddy-current flexible speed regulation device for preventing overheating

A permanent magnet eddy current and flexible adjustment technology, which is applied in the direction of electromechanical devices, permanent magnet clutches/brakes, magnetic circuit rotating parts, etc., can solve the problems that restrict the development and application of high-power permanent magnet eddy current transmission products, and cannot issue high temperature alarms in time , can not guarantee the temperature measurement and other problems, to achieve the effect of solving adverse effects, improving the accuracy of temperature measurement, and avoiding inaccurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

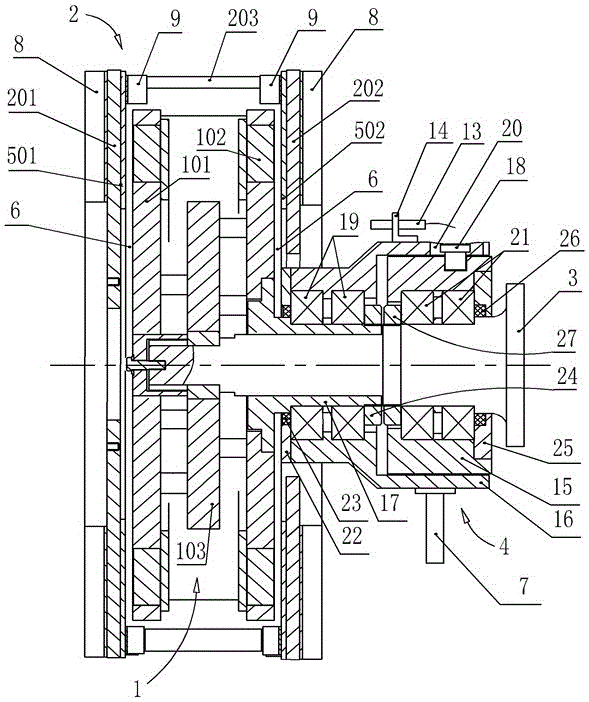

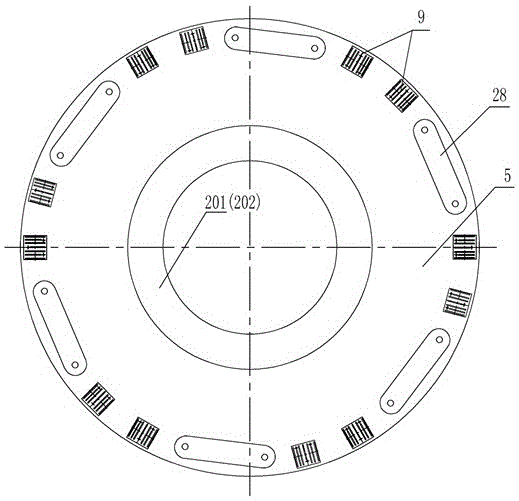

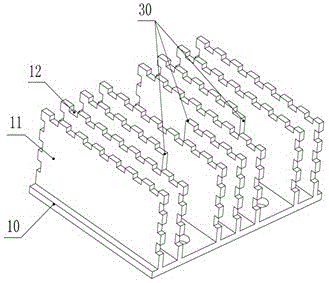

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0028] See figure 1 , is a structural schematic diagram of an embodiment of an air-cooled permanent magnet eddy current flexible speed control device for preventing overheating according to the present invention, including a permanent magnet rotor 1, a conductor rotor 2, a main shaft 3 and an air gap adjustment mechanism 4, and the permanent magnet rotor 1 is provided with a permanent magnet rotor. Disk 1 101, permanent disk 2 102 and intermediate disk 103, conductor rotor 2 is provided with conductor disk 1 201, conductor disk 2 202 and spacer bracket 203, and the back side of conductor disk 1 201 and conductor disk 2 202 are equipped with main heat dissipation Sheet 8, conductor 5 is all provided with conductor 5 on the opposite inner surface of conductor disk one 201 and conductor disk two 202, between conductor one 501 and the coupling surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com