A master-slave electromechanical servo cooperative motion control system

A technology of servo control and cooperative motion, applied in control systems, vector control systems, motor generator control, etc., can solve the problems of large specific power and load requirements, low dynamic performance indicators, etc., and achieve high power-to-mass ratio and low product cost Moderate, compact space layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

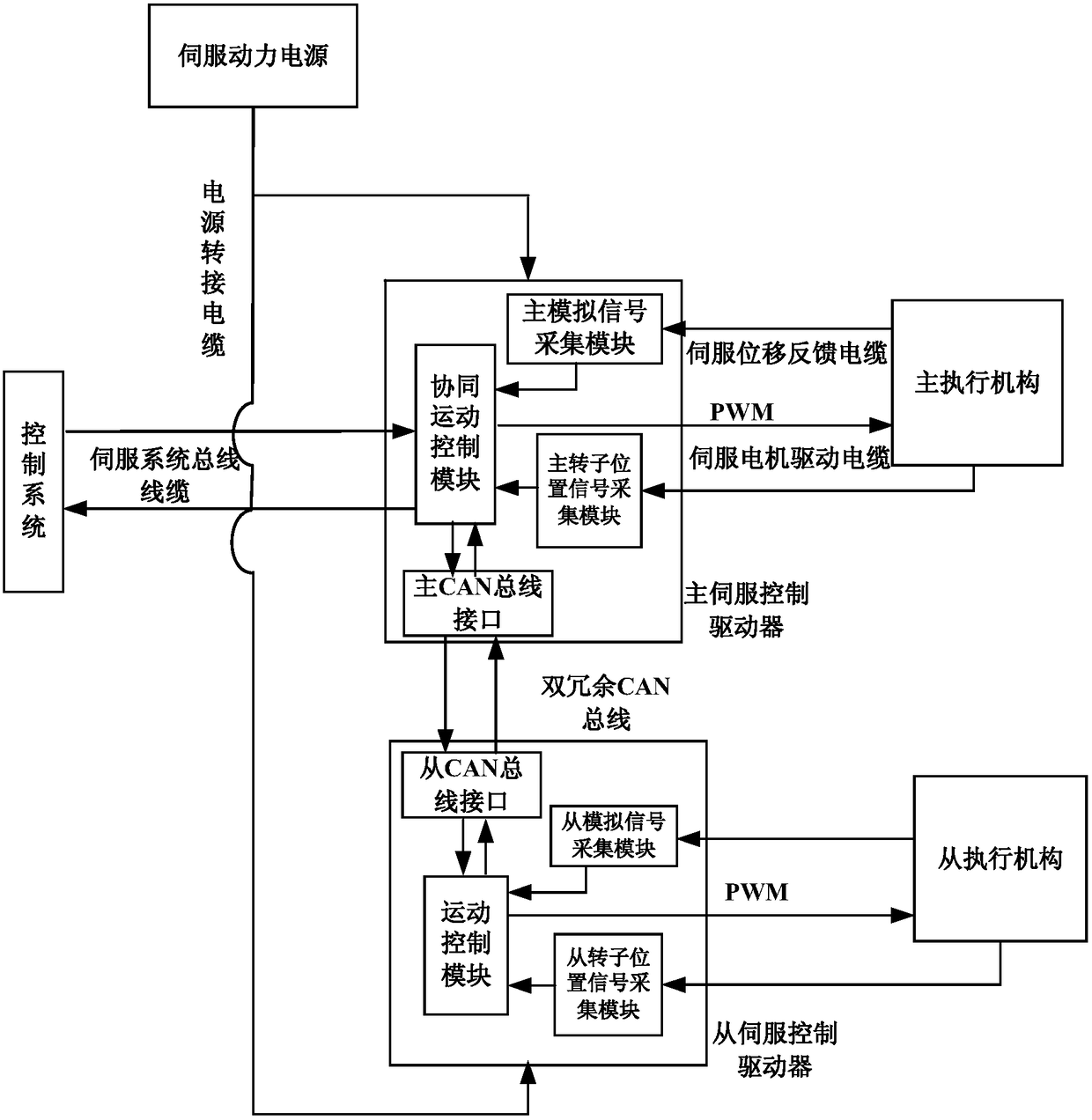

[0032] The main task of the main servo control driver is to receive all kinds of instructions issued by the control system, generate an interrupt after receiving the bus message of the control system and enter the interrupt service program, and perform various operations required by the bus protocol; and communicate through the dual redundant CAN bus Query whether a new CAN message is received in the timer interrupt service program, and receive the running status of the slave servo control driver and the slave actuator in real time. According to the required nozzle swing angle, calculate the expansion and contraction lengths corresponding to the master and slave actuators in real time, and adjust the acceleration factor and jerk factor of the master and slave motion trajectories in real time to realize the master and slave actuators. Real-time m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com