Phenolic resin foam and manufacturing method thereof

A technology of phenolic resin and foam, applied in the direction of chemical instruments and methods, layered products, building components, etc., can solve the problems of storage place, storage method limitation, increase flame spread speed, etc., and achieve excellent flame retardancy, The effect of maintaining thermal insulation performance and excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

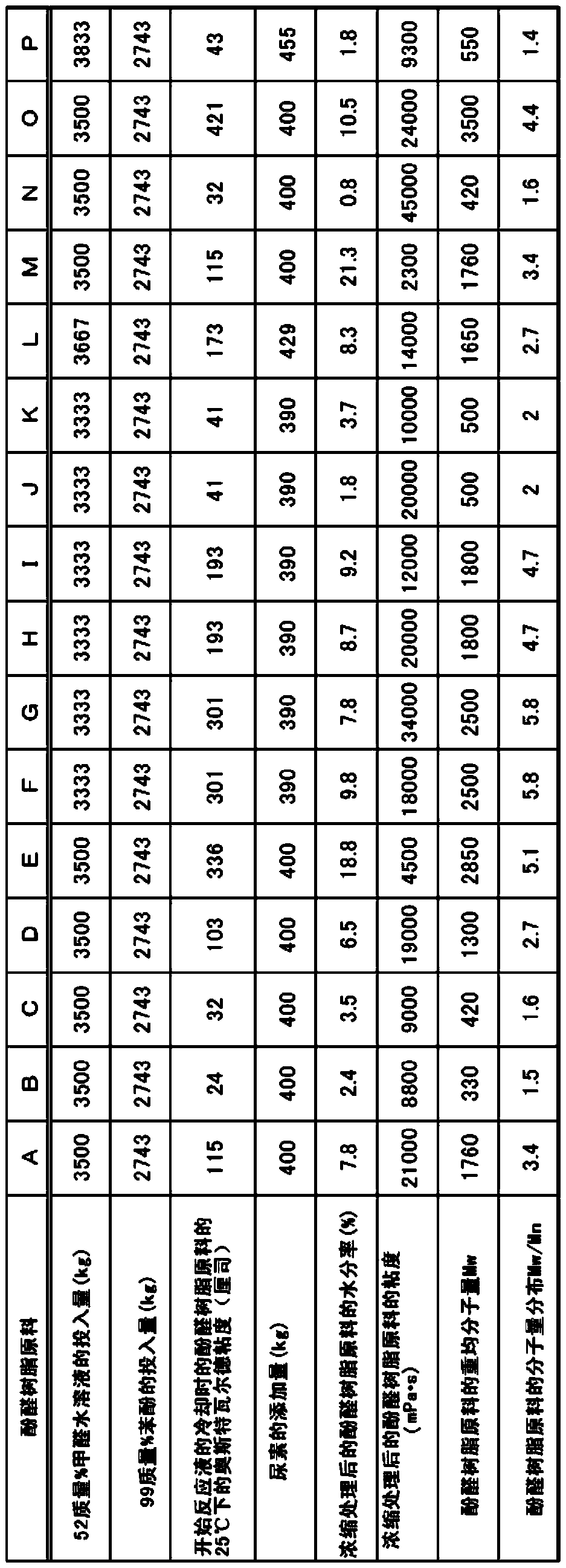

Method used

Image

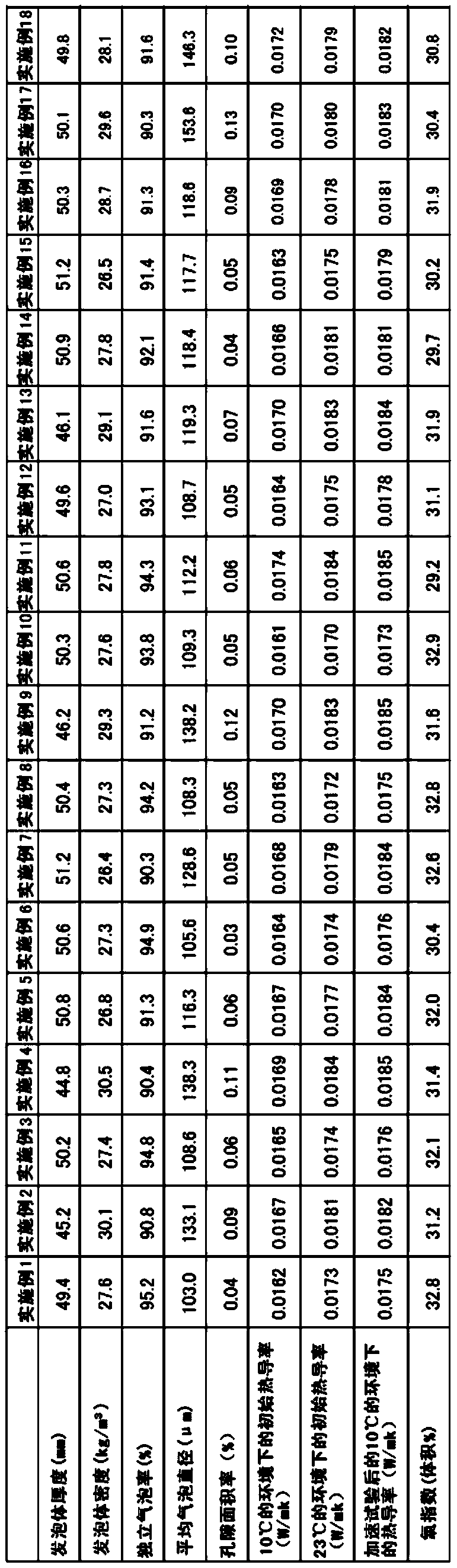

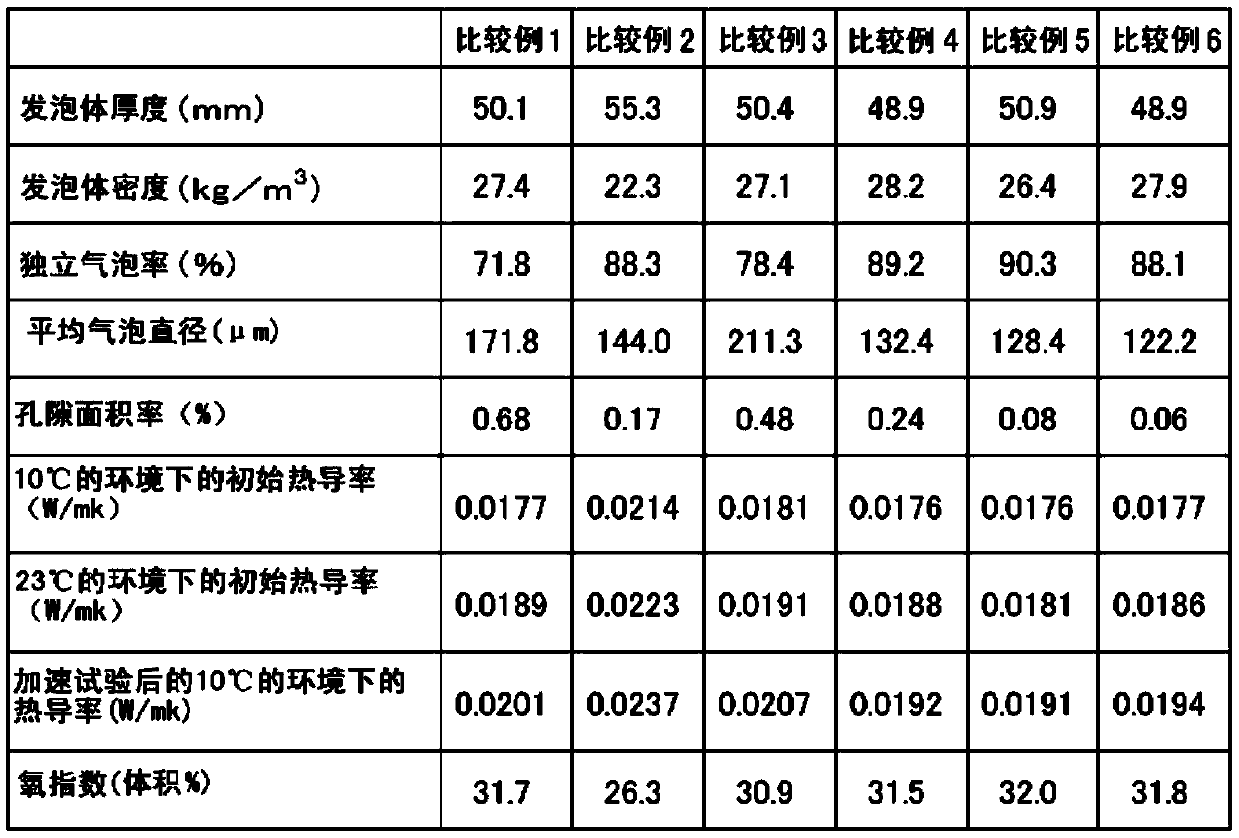

Examples

Embodiment 1

[0125] Manufacture of phenolic resin foam

[0126] 50% by mass and 50% by mass of ethylene oxide-propylene oxide block copolymers and polyoxyethylene dodecylphenyl ether compositions as surfactants with respect to 100 parts by mass of phenolic resin Raw material A was mixed in a ratio of 3.0 parts by mass. 11 parts by mass of 1-chloro-3,3,3-trifluoropropene as a foaming agent and 14 parts by mass of A mixture of 80% by mass of xylenesulfonic acid and 20% by mass of diethylene glycol as an acid curing catalyst. The foamable phenolic resin composition as the final mixture is dispensed from a branch pipe, and supplied onto the moving surface material.

[0127] The surface opposite to the surface contacting the surface material of the foamable phenolic resin composition on the surface material is covered with another surface material, and the foamable phenolic resin composition is sandwiched between the two surface materials. In this state, the foamable phenolic resin compositi...

Embodiment 2

[0130] The foaming agent was changed to 1,3,3,3-tetrafluoro-1-propene, and 8 parts by mass of the aforementioned foaming agent was added to 100 parts by mass of the mixture of the surfactant and the phenolic resin raw material. Example 1 was carried out in the same manner to obtain a phenolic resin foam.

Embodiment 3

[0132] The foaming agent was changed to 1,1,1,4,4,4-hexafluoro-2-butene, and 14 parts by mass of the aforementioned foam was added to 100 parts by mass of a mixture of a surfactant and a phenolic resin raw material. Except for the foaming agent, it carried out similarly to Example 1, and obtained the phenolic resin foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bubble diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com