Thermal isolation techniques

A heat and thermal barrier technology, applied in the direction of cooling/ventilation/heating transformation, modification through conduction heat transfer, climate sustainability, etc., can solve the problems of noisy cooling system, increasing the total energy consumption of the system, and increasing the cost of the system, etc. Achieve the effect of reducing thermal problems and increasing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

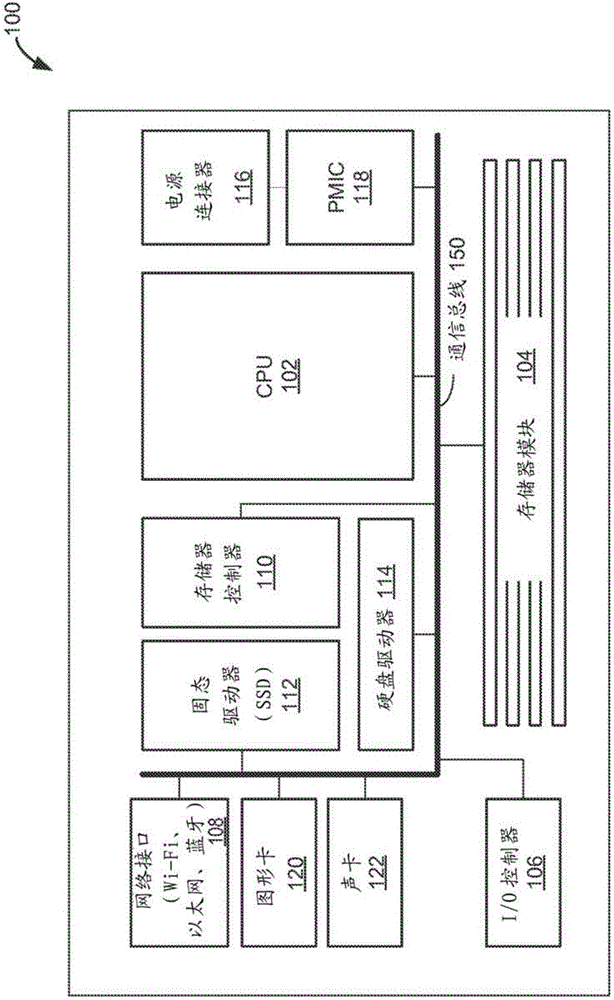

[0021] Various embodiments described herein include systems, methods, and / or devices for use by or integrated into electronic assemblies. In particular, the electronic systems, heat sinks, and methods of heat dissipation described herein facilitate the dissipation of heat generated by electronic components in the electronic system.

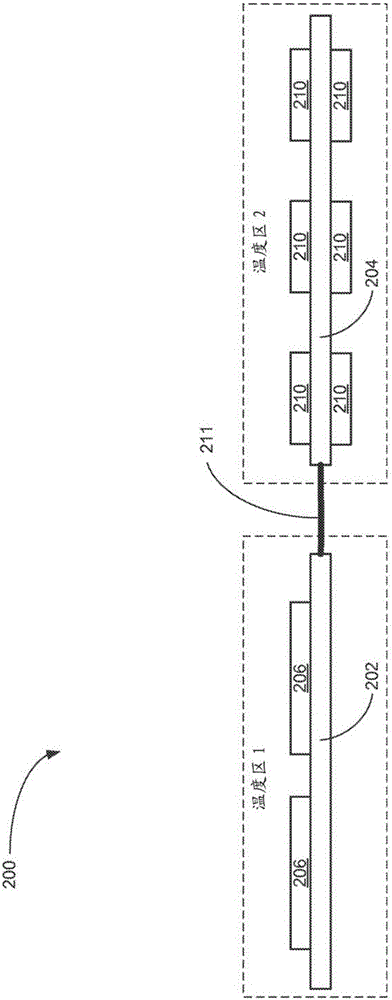

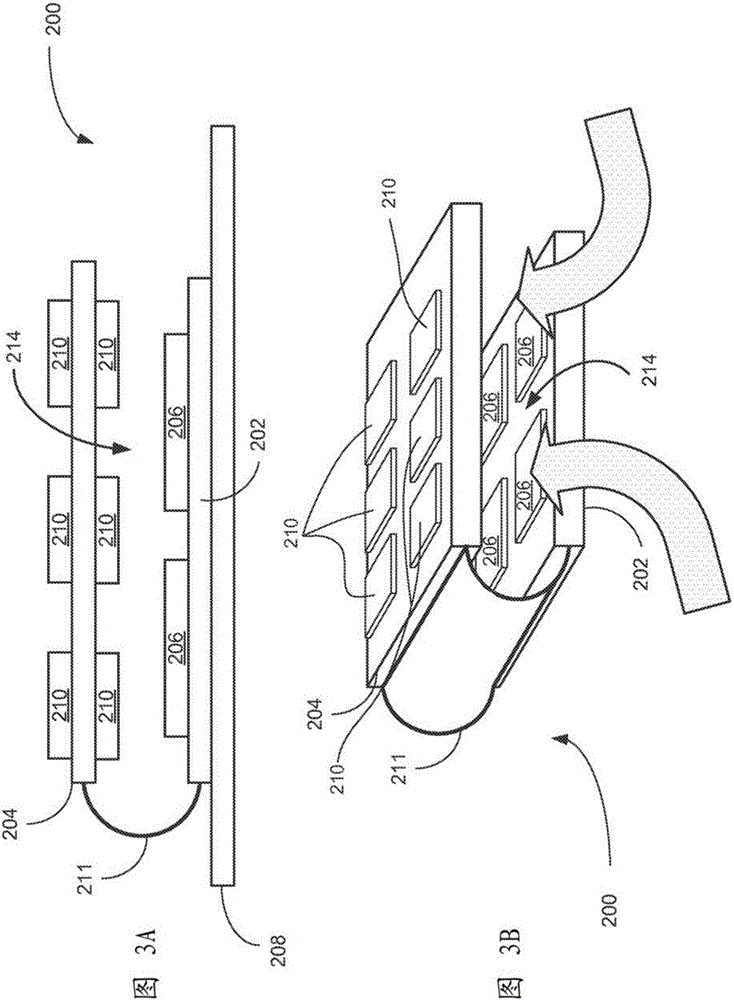

[0022] Embodiments described herein allow isolation of heat sensitive devices from heat generating devices on a PCBA (printed circuit board assembly). In some embodiments, the thermal barrier is formed by using a thermal barrier interconnect, such as a flex circuit board between two rigid printed circuit boards. This thermal barrier is used to allow one plate to operate at a lower temperature relative to the other plates. For example, a board with NAND flash may operate at a lower temperature relative to a board containing a NAND flash controller and power electronics. The difference in temperature between plates can be as high as 20 °C. This m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com