Method for preparing electronic tobacco juice from tobacco raw material by using alkali type low-temperature dry distillation process

An electronic cigarette liquid and dry distillation technology, which is applied in the field of electronic cigarettes, can solve the problems of burnt taste, sour taste, and high acidic content of dry distillation products, and achieves the effects of solving sour taste, making up for lack of flavor, and retaining tobacco flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

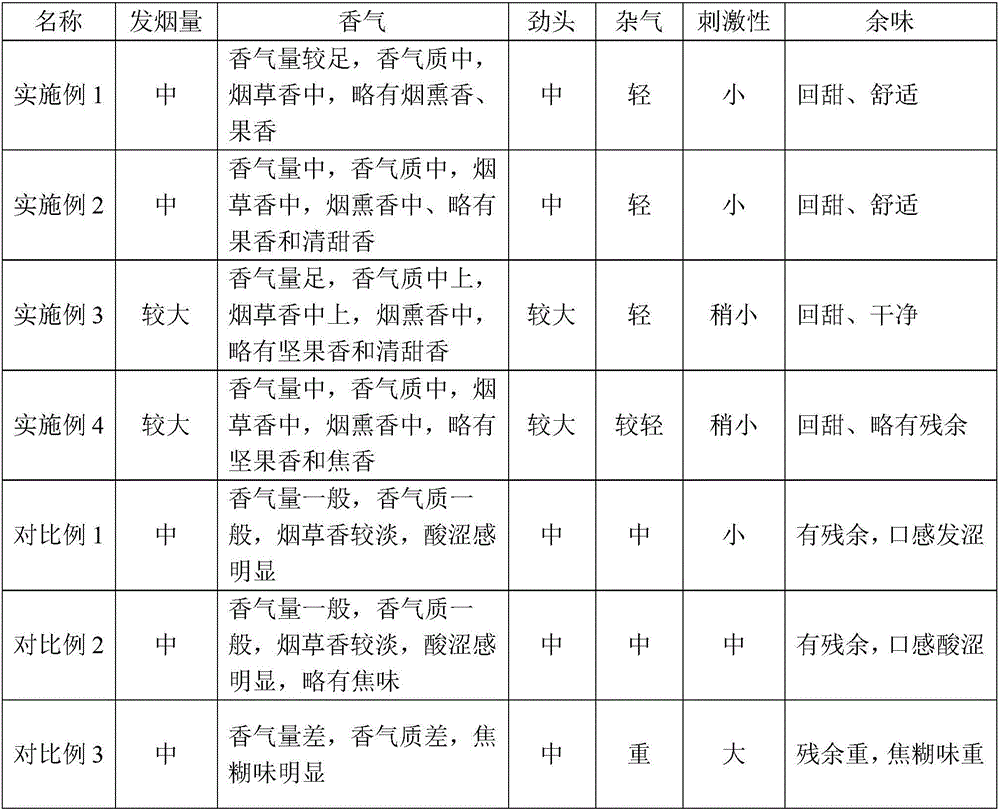

Examples

Embodiment 1

[0027] Weigh 5g of shredded tobacco and lay it flat on the tray, spray 5% w / w sodium hydroxide aqueous solution evenly on the surface of the shredded tobacco according to 1% of the mass of the shredded tobacco, transfer the shredded tobacco to the aluminum retort of the carbonization furnace, feed nitrogen gas, and program the temperature of the carbonization furnace When the temperature reaches 180°C, the carbonized product is taken out of the carbonization furnace by the carrier gas through the conduit, and is collected by an absorption bottle containing 30mL of e-cigarette solvent in a cold trap to obtain a dry distillation extract of shredded tobacco.

[0028] The obtained dry distillate solution is added with guaiacol, damascenone, dihydrodamascenone and 4-hydroxy-2,5-dimethyl-3(2H)-furanone, and mixed to obtain electronic cigarette liquid ; Wherein the mass ratio of guaiacol and tobacco dry distillation extract, the mass ratio of damascenone and tobacco dry distillation e...

Embodiment 2

[0030] Weigh 5g cut stems and lay them flat on the tray, spray 5% w / w ammonia water evenly on the surface of the cut stems according to 3% of the cut stems mass, transfer the cut stems to the aluminum retort of the retort furnace, feed nitrogen gas, and perform temperature-programmed retort The furnace was heated to 200°C, and the retort product was taken out of the retort furnace by the carrier gas through the conduit, and was collected by an absorption bottle containing 30mL of e-cigarette solvent in a cold trap, to obtain dry distillation extract of shredded stems.

[0031] The obtained dry distillate solution is added with guaiacol, damascenone, dihydrodamascenone and 4-hydroxy-2,5-dimethyl-3(2H)-furanone, and mixed to obtain electronic cigarette liquid ; Wherein the mass ratio of guaiacol and tobacco dry distillation extract, the mass ratio of damascenone and tobacco dry distillation extract, the mass ratio of dihydrodamascenone and tobacco dry distillation extract and 4-h...

Embodiment 3

[0033] Weigh 5g of shredded tobacco and lay it flat on the tray, spray 10% w / w sodium bicarbonate aqueous solution evenly on the surface of the shredded tobacco according to 5% of the mass of the shredded tobacco, transfer the shredded tobacco to the aluminum retort of the carbonization furnace, introduce air, and program the temperature of the carbonization furnace When the temperature reaches 240°C, the carbonized product is taken out of the carbonization furnace by the carrier gas through the conduit, and is collected by an absorption bottle containing 30mL of e-cigarette solvent in a cold trap to obtain a dry distillation extract of shredded tobacco.

[0034] The obtained dry distillate solution is added with guaiacol, damascenone, dihydrodamascenone and 4-hydroxy-2,5-dimethyl-3(2H)-furanone, and mixed to obtain electronic cigarette liquid ; Wherein the mass ratio of guaiacol and tobacco dry distillation extract, the mass ratio of damascenone and tobacco dry distillation ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com