Processing method of defatted pumpkin seed cheese

A processing method and a technology for pumpkin seeds are applied in the processing field of defatted pumpkin seed cheese, which can solve the problem of less products derived from pumpkin seeds, and achieve the effects of rich nutrients, low moisture content and easy transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

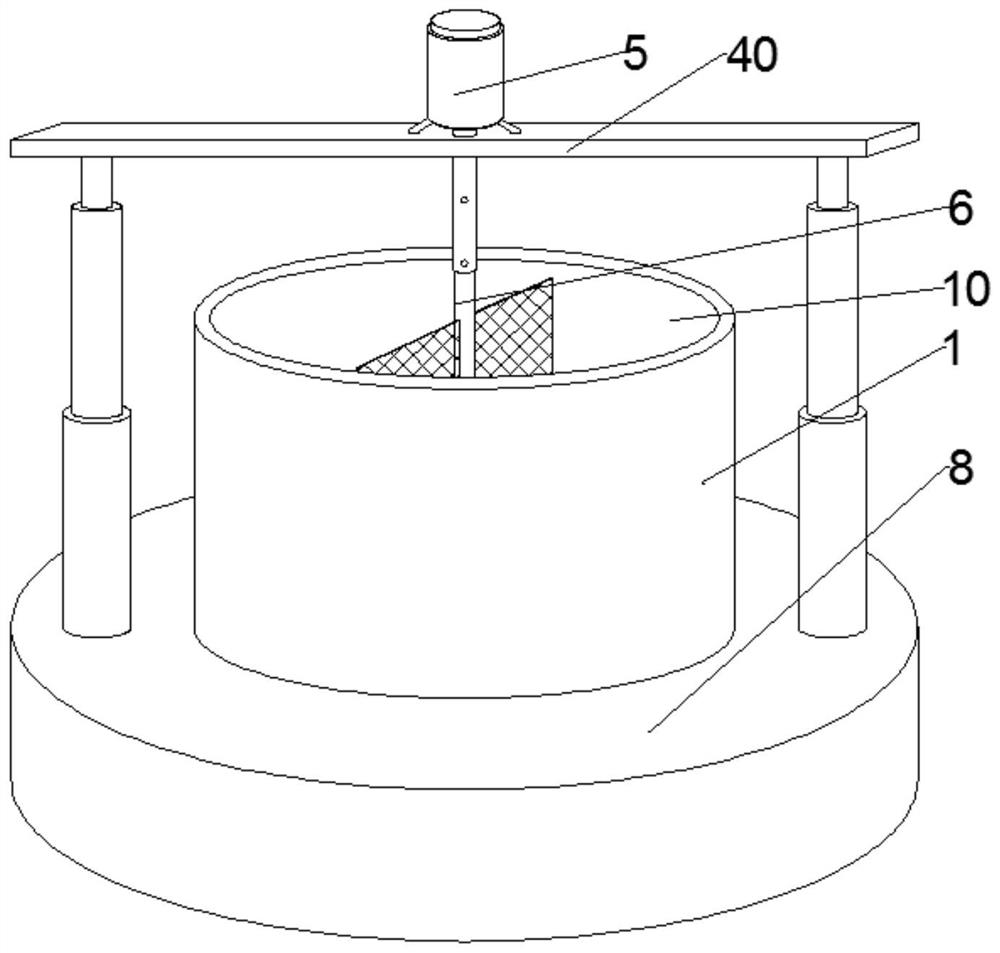

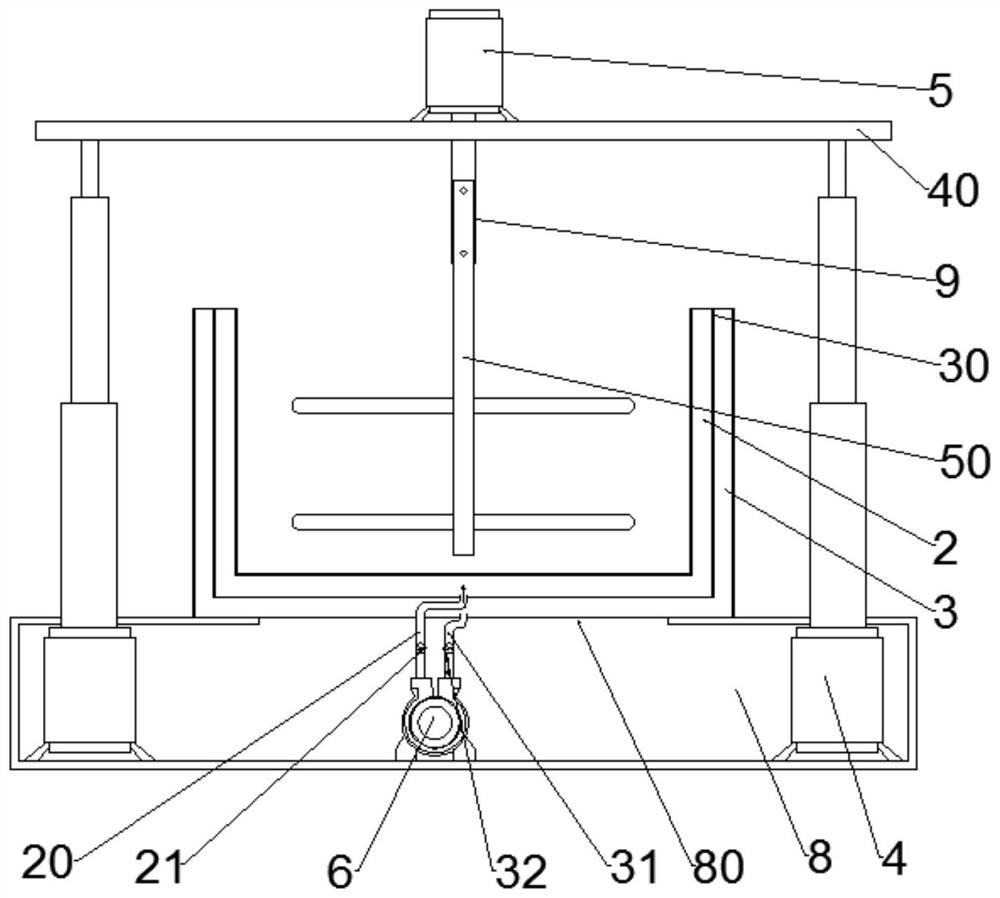

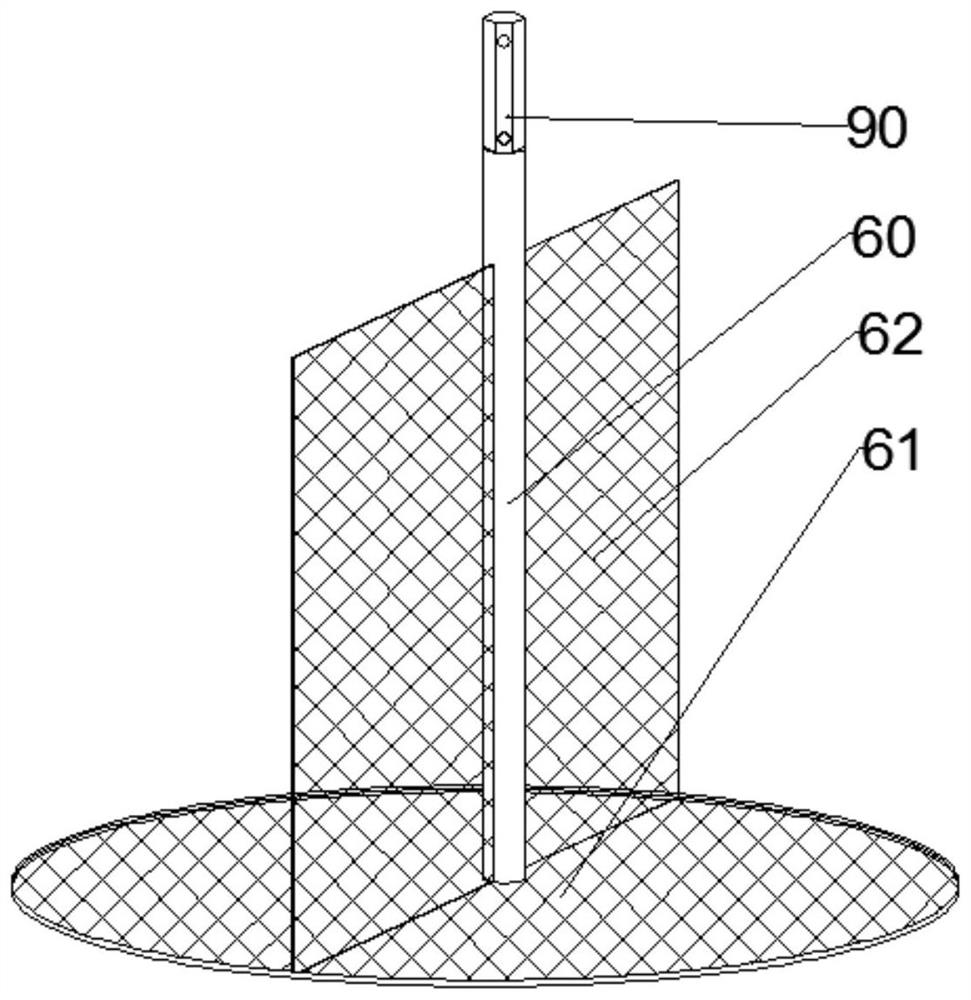

Image

Examples

Embodiment 1

[0040] The processing method of defatted pumpkin seed cheese comprises the following steps:

[0041] S1. Put the pumpkin seeds with naked kernels in a colloid mill, add water to homogenate, and filter through a 200-mesh sieve to obtain pumpkin seed pulp, wherein the mass ratio of pumpkin seeds with naked kernels to the added water is 1:6;

[0042] S2. Put the pumpkin seed pulp through a centrifuge at 10,000 r / min, centrifuge for 10 minutes, remove the upper layer of grease, and sterilize it at 60° C. for 30 minutes to obtain degreased pumpkin seed pulp;

[0043]S3, add defatted pumpkin seed pulp to pure milk (pasteurized milk) and mix and stir evenly to obtain a raw material liquid, add a starter to the raw material liquid, and stir evenly to obtain a compound liquid, wherein the starter is a mass ratio of 1:1 mixed bacteria of Streptococcus thermophilus and Bacillus bulgaricus, the concentration of the starter is 5g / L, and the volume fraction of deesterified pumpkin seed pulp...

Embodiment 2

[0046] The processing method of defatted pumpkin seed cheese comprises the following steps:

[0047] S1. Put the pumpkin seeds with naked kernels in a colloid mill, add water to homogenate, and filter through a 200-mesh sieve to obtain pumpkin seed pulp, wherein the mass ratio of pumpkin seeds with naked kernels to the added water is 1:6;

[0048] S2. Put the pumpkin seed pulp through a centrifuge at 5000r / min, centrifuge for 15min, remove the upper layer of grease, and sterilize it at 70°C for 30min to obtain defatted pumpkin seed pulp;

[0049] S3. Add a leavening agent to pure milk, and mix defatted pumpkin seed pulp accounting for 1 times its volume and stir evenly to obtain a compound solution, wherein the leavening agent is Streptococcus thermophilus and Streptococcus thermophilus with a mass ratio of 1:1. The mixed bacteria of Bacillus bulgaricus, the concentration of the starter is 1g / L;

[0050] S4. Control the temperature to 39°C, sterilize at 95°C for 5 minutes aft...

Embodiment 3

[0052] The processing method of defatted pumpkin seed cheese comprises the following steps:

[0053] S1. Put the pumpkin seeds with naked kernels in a colloid mill, add water to homogenate, and filter through a 200-mesh sieve to obtain pumpkin seed pulp, wherein the mass ratio of pumpkin seeds with naked kernels to the added water is 1:6;

[0054] S2. Put the pumpkin seed pulp through a centrifuge at 8000r / min, centrifuge for 13 minutes, remove the upper layer of grease, and sterilize it at 65°C for 30 minutes to obtain degreased pumpkin seed pulp;

[0055] S3. Adding a leavening agent to the pure milk, mixing defatted pumpkin seed pulp accounting for 2.3 times its volume and stirring evenly to obtain a compound solution, wherein the leavening agent is Streptococcus thermophilus and Streptococcus thermophilus with a mass ratio of 1:1 The mixed bacteria of Bacillus bulgaricus, the concentration of the starter is 4g / L;

[0056] S4. Control the temperature to 39° C., sterilize a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com