Cooperative processing system for hazardous wastes and high-concentration salty waste water and method thereof

A high-concentration salt-containing and co-processing technology is applied in the field of co-processing systems for hazardous waste and high-concentration salt-containing wastewater, which can solve problems such as poor adaptability, and achieve the effects of low operating costs and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

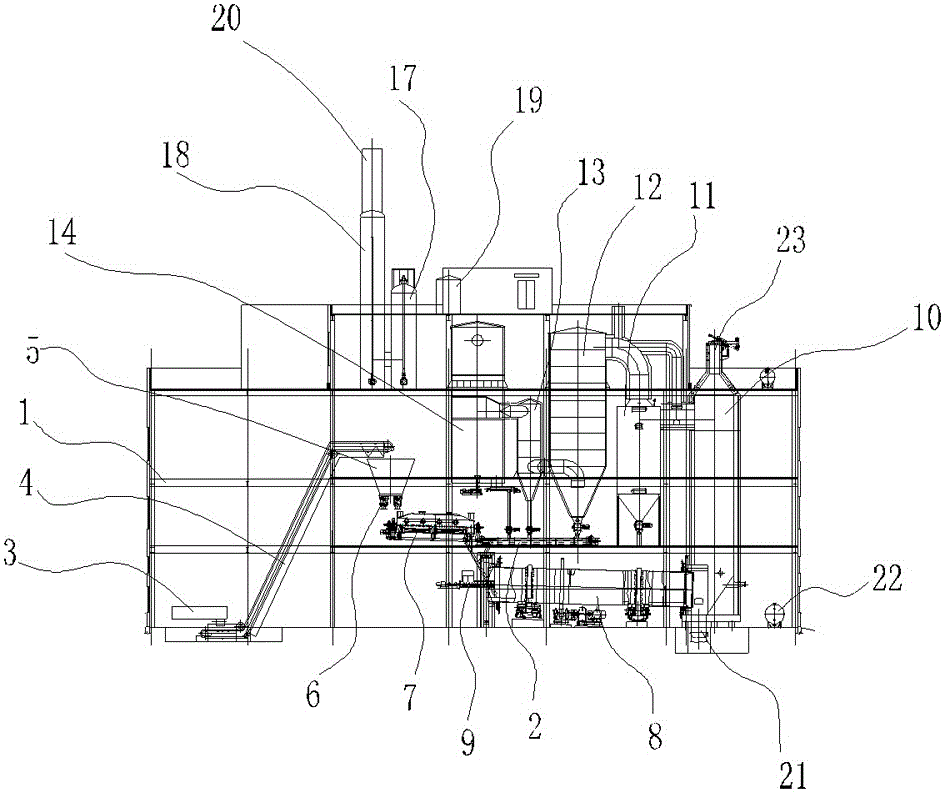

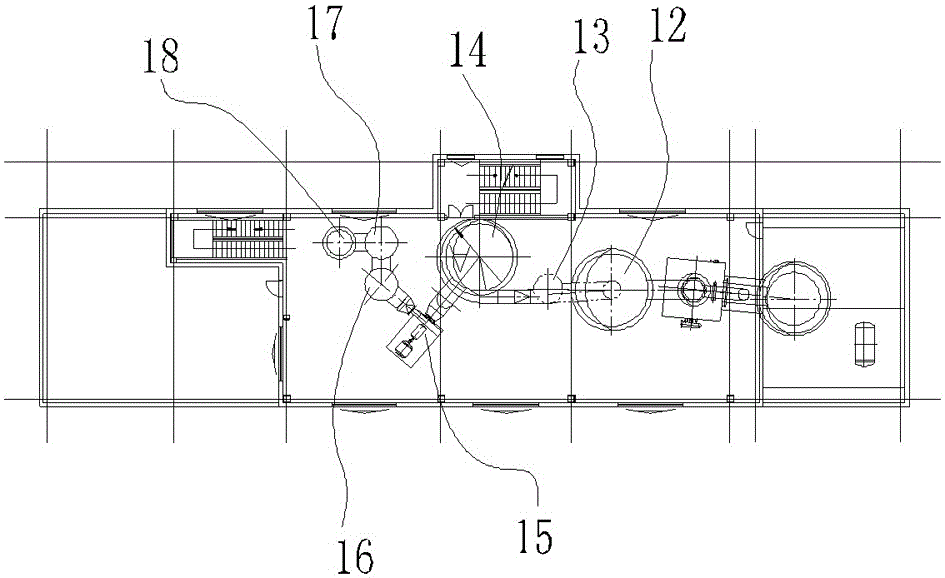

[0040] Embodiment 1: as figure 1 and figure 2 As shown, a cooperative treatment system for hazardous waste and high-concentration saline wastewater includes a treatment frame 1, a waste heat utilization drying incineration treatment device and a condenser 2, and the treatment frame 1 is equipped with a wet solid waste conveyor 3 , the waste heat utilization drying incineration treatment device includes a large-inclination conveyor 4, the wet solid waste conveyor 3 is arranged at the bottom of the large-inclination conveyor 4, and the bottom of the high-inclination conveyor 4 is arranged below the upper end There is a high-level storage tank 5 matched with the large-inclination conveyor 4, a discharge auger 6 is installed at the bottom of the high-position storage tank 5, and a paddle dryer 7 is arranged below the discharge auger 6. The top of the paddle dryer 7 communicates with the condenser 2, the bottom end of the paddle dryer 7 and the bottom end of the condenser 2 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com