Preparing method for antibacterial nanofiltration membrane with ultrafiltration membrane as base membrane

A technology of ultrafiltration membrane and nanofiltration membrane, which is applied in the field of nanofiltration membrane, can solve the problems of insufficient antibacterial performance of nanofiltration membrane, low efficiency of nanofiltration membrane production, and need for more organic solvents, etc., so as to improve the service life and stability of use, short assembly time, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

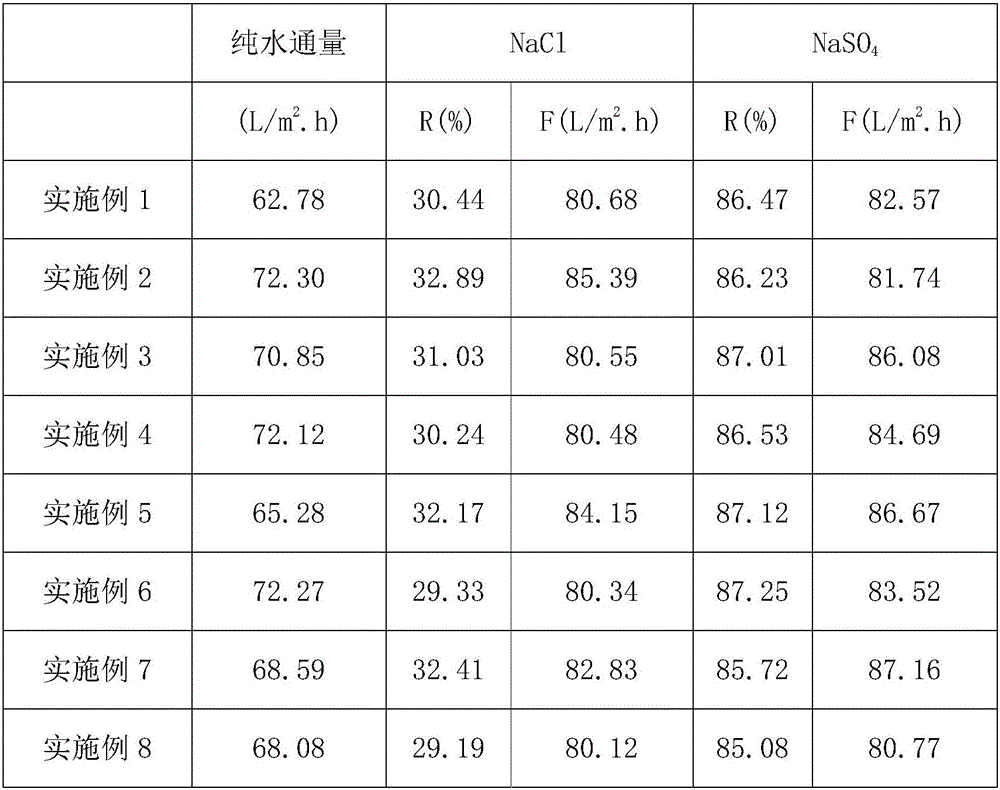

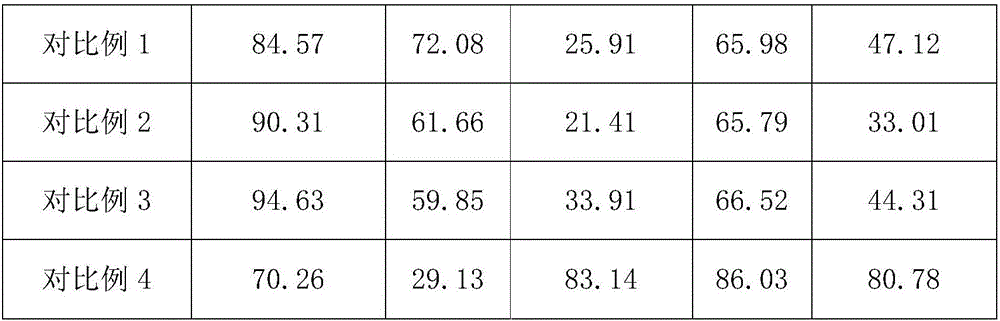

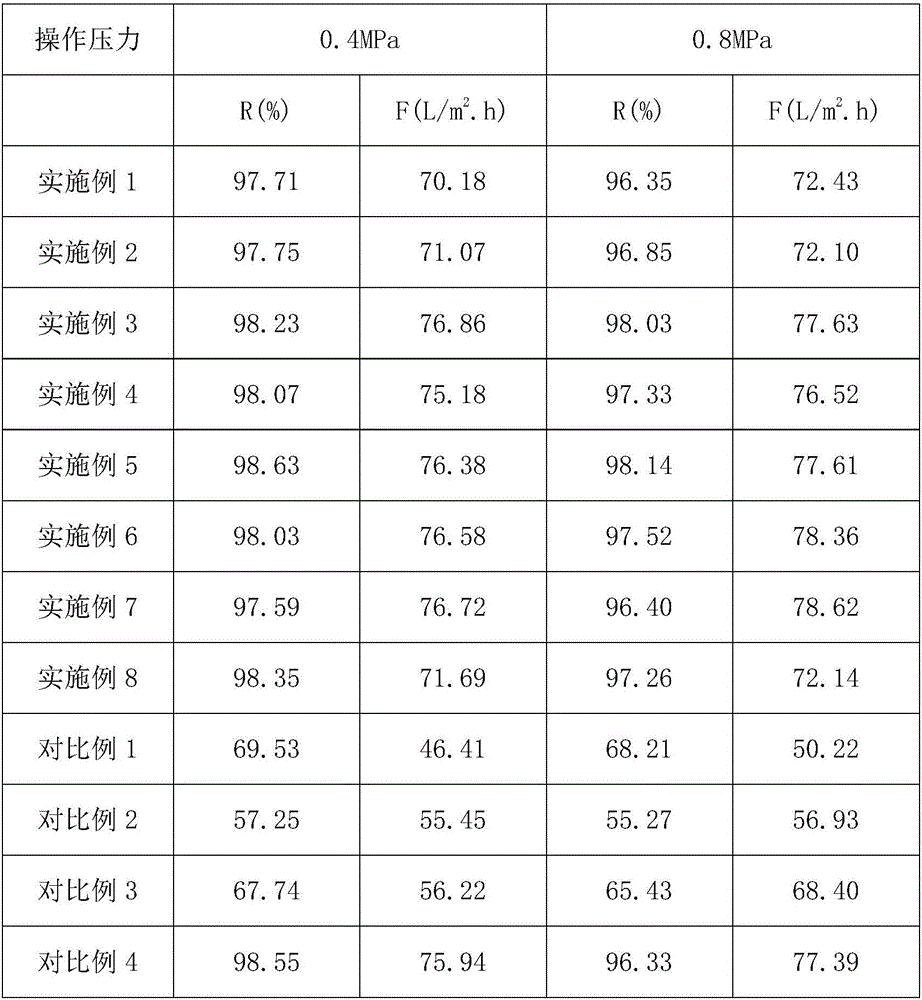

Examples

Embodiment 1

[0031] A preparation method of an antibacterial nanofiltration membrane using an ultrafiltration membrane as a base membrane, comprising the following steps:

[0032] The first step: soak the charged ultrafiltration membrane in polyallyl ammonium chloride solution (mass concentration is 0.1%) under vacuum state, add dropwise sodium hydroxide to adjust the pH value of the solution to 10.0, and the ultrafiltration The membrane is fixed in a container with a porous support layer, the membrane is facing up, and then the polyallyl ammonium chloride solution is injected into the container under pressure, and the ultrafiltration membrane is combined with the polyallyl ammonium chloride, and the assembly time is Obtain polycation composite membrane in 20 minutes;

[0033] The second step: use deionized water to clean the polycation composite membrane (cleaning time is 20 seconds), then soak the polycation polymer membrane in polyethylene sulfate solution (mass concentration is 0.2%), ...

Embodiment 2

[0036] A preparation method of an antibacterial nanofiltration membrane using an ultrafiltration membrane as a base membrane, comprising the following steps:

[0037] The first step: soak the charged ultrafiltration membrane in polyallyl ammonium chloride solution (mass concentration is 0.3%) under vacuum state, add dropwise sodium hydroxide to adjust the pH value of the solution to 10.2, and the ultrafiltration The membrane is fixed in a container with a porous support layer, the membrane is facing up, and then the polyallyl ammonium chloride solution is injected into the container under pressure, and the ultrafiltration membrane is combined with the polyallyl ammonium chloride, and the assembly time is Obtain polycation composite membrane in 25 minutes;

[0038] The second step: use deionized water to clean the polycation composite membrane (cleaning time is 30 seconds), then soak the polycation polymer membrane in polyethylene sulfate solution (mass concentration is 0.5%), ...

Embodiment 3

[0041] A preparation method of an antibacterial nanofiltration membrane using an ultrafiltration membrane as a base membrane, comprising the following steps:

[0042] The first step: soak the charged ultrafiltration membrane in polyallyl ammonium chloride solution (mass concentration is 0.1%) under vacuum state, add dropwise sodium hydroxide to adjust the pH value of the solution to 10.2, and the ultrafiltration The membrane is fixed in a container with a porous support layer, the membrane is facing up, and then the polyallyl ammonium chloride solution is injected into the container under pressure, and the ultrafiltration membrane is combined with the polyallyl ammonium chloride, and the assembly time is Obtain polycation composite membrane in 20 minutes;

[0043] The second step: use deionized water to clean the polycation composite membrane (cleaning time is 30 seconds), then soak the polycation polymer membrane in polyethylene sulfate solution (mass concentration is 0.2%), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com