Recovery process of anion exchange resin in a solvent recovery process

A technology of exchange resin and anion, applied in the field of recovery process of ion exchange resin, can solve the problems of rising electrical conductivity, increasing production cost, blocking ion exchange channels, etc., to achieve the effect of improving exchange capacity, long service life and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

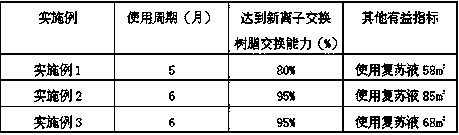

Embodiment 1

[0039] Embodiment 1 Recovery process of anion exchange resin in a solvent recovery process

[0040] Anion exchange resin resuscitation fluid composition

[0041] Anion exchange resin resuscitating fluid of the present invention is alkaline common saline;

[0042] The alkaline salt solution is a solution formed by dissolving sodium chloride and sodium hydroxide in water;

[0043] The concentration of sodium chloride in the alkaline saline: 15%; the concentration of sodium hydroxide: 3%;

[0044] The amount of alkaline salt water: 58m 3 ;Specification of anion resin: 15m 3 .

[0045] Anion Exchange Resin Recovery Procedure

[0046] Anion exchange resin recovery was carried out three times; each recovery was divided into two steps of static and dynamic top water; after the third recovery was completed, positive washing and backwashing were performed, and regeneration was performed when the pH reached 9;

[0047] The regeneration volume is 3BV; 3BV refers to 3 times the volu...

Embodiment 2

[0068] Embodiment 2 Recovery process of anion exchange resin in a solvent recovery process

[0069] Anion exchange resin resuscitation fluid composition

[0070] Anion exchange resin resuscitating fluid of the present invention is alkaline common saline;

[0071] The alkaline salt solution is a solution formed by dissolving sodium chloride and sodium hydroxide in water;

[0072] The concentration of sodium chloride in the alkaline salt water: 13%; the concentration of sodium hydroxide: 2.5%;

[0073] The amount of alkaline salt water: 85m 3 ;Specification of anion resin: 15m 3 .

[0074] Anion Exchange Resin Recovery Procedure

[0075] Anion exchange resin recovery was carried out three times; each recovery was divided into two steps of static and dynamic top water; after the third recovery was completed, positive washing and backwashing were performed, and regeneration was performed when the pH reached 9;

[0076] The regeneration volume is 3BV; 3BV refers to 3 times th...

Embodiment 3

[0097] Example 3 Recovery process of anion exchange resin in a solvent recovery process

[0098] Anion exchange resin resuscitation fluid composition

[0099] Anion exchange resin resuscitating fluid of the present invention is alkaline common saline;

[0100] The alkaline salt solution is a solution formed by dissolving sodium chloride and sodium hydroxide in water;

[0101] The concentration of sodium chloride in the alkaline salt water: 15%; the concentration of sodium hydroxide: 2.5%;

[0102] The amount of alkaline salt water: 68m 3 ;Specification of anion resin: 15m 3 .

[0103] Anion Exchange Resin Recovery Procedure

[0104] Anion exchange resin recovery was carried out three times; each recovery was divided into two steps of static and dynamic top water; after the third recovery was completed, positive washing and backwashing were performed, and regeneration was performed when the pH reached 9;

[0105] The regeneration volume is 3BV; 3BV refers to 3 times the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com