Full-automatic sapphire grinding machine

A sapphire and grinding machine technology, which is applied in the direction of grinding machine tools, grinding devices, grinding racks, etc., can solve the problems of trying to integrate without sapphire, and achieve the effect of improving environmental protection efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

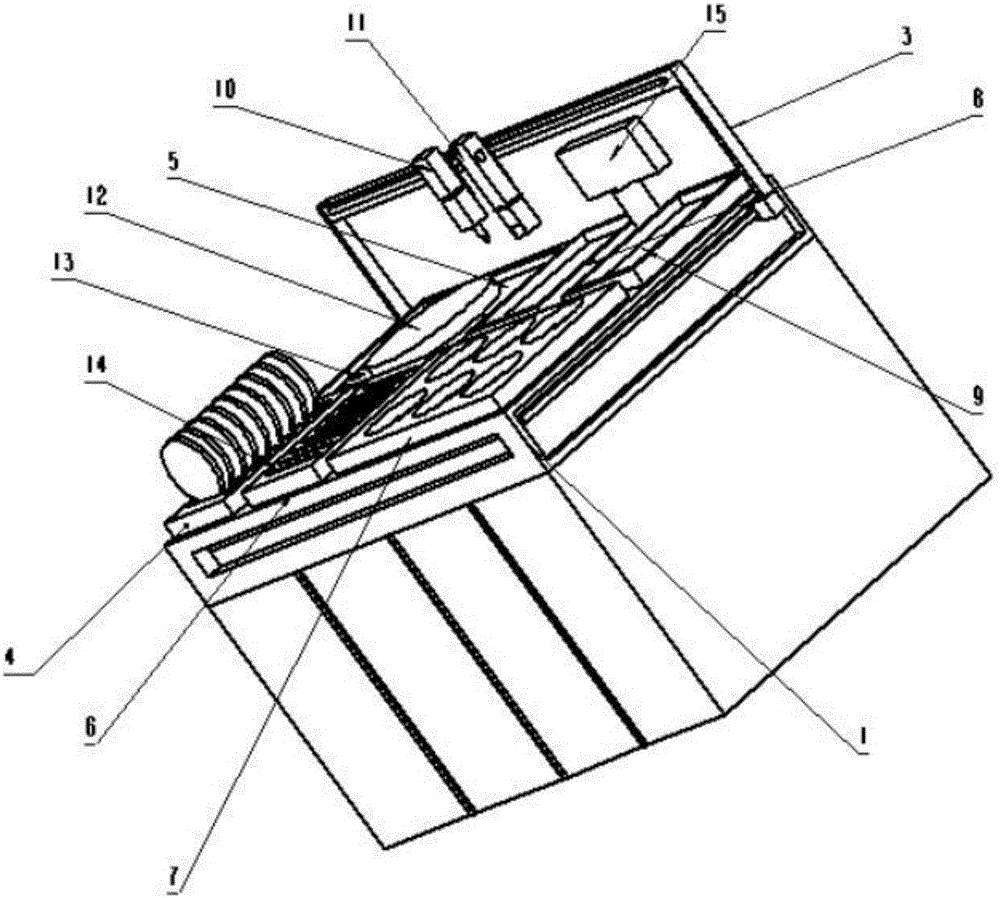

[0022] combine figure 1 make an explanation, figure 1 Suitable materials shown include, but are not limited to, disc or lens shapes.

[0023] A full-automatic sapphire grinding machine, comprising a frame provided with an operating table 1, an X-direction beam 3 slidingly connected with the frame 2 in the Y direction, and a control system. The operating table 1 includes a raw material area 4 provided with eight slots , the positioning grinding area 5, the cleaning area 6 provided with eight cleaning tanks 14, the waste liquid area located directly below the positioning grinding area 5 and the cleaning area 6 is located in the cabinet under the operating table 1, not shown in the figure, provided with The inspection area 7, waste area 8 and finished product area 9 of the six inspection tanks, the X-direction beam 3 is provided with a Z-direction liquid gun 10 and a Z-direction manipulator 11, and the positioning grinding area 5, Z-direction liquid gun 10 and the Z-direction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com