Semi-automatic mold polishing device capable of preventing flying chips

A polishing device and semi-automatic technology, applied in grinding/polishing safety devices, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of debris splashing, inability to clean debris, etc., to improve utilization, improve Operational efficiency and the effect of improving environmental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

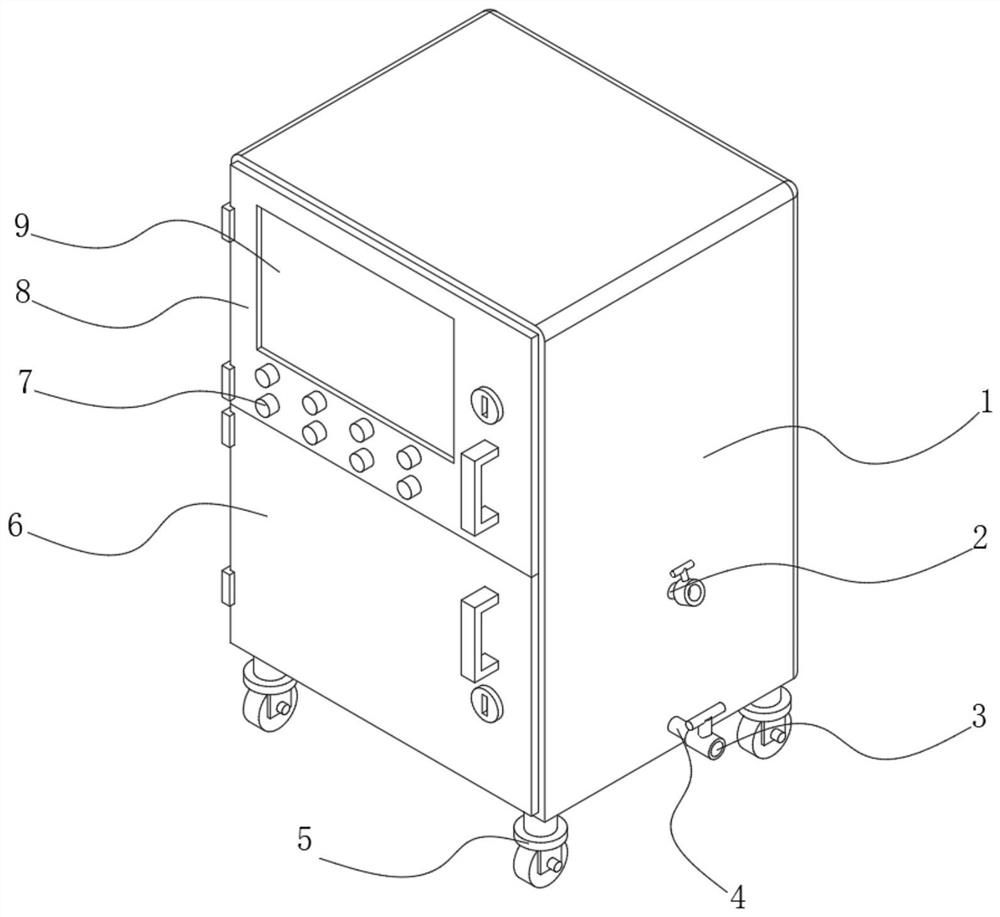

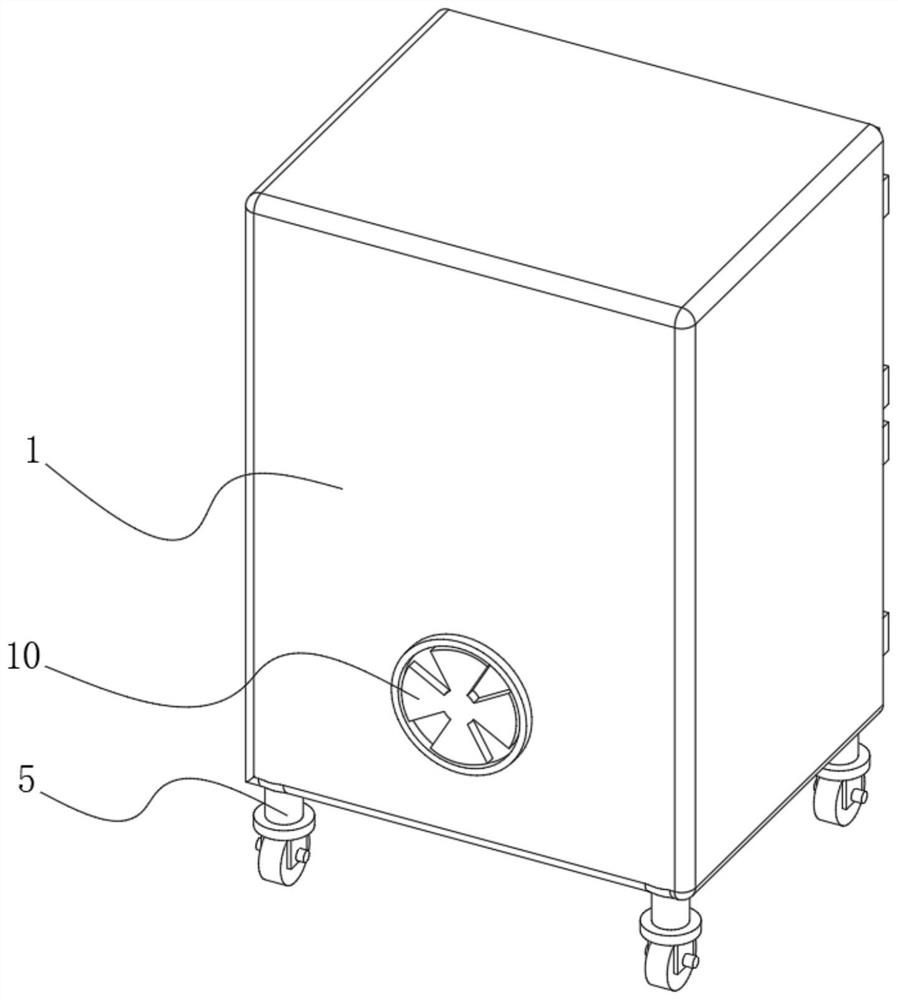

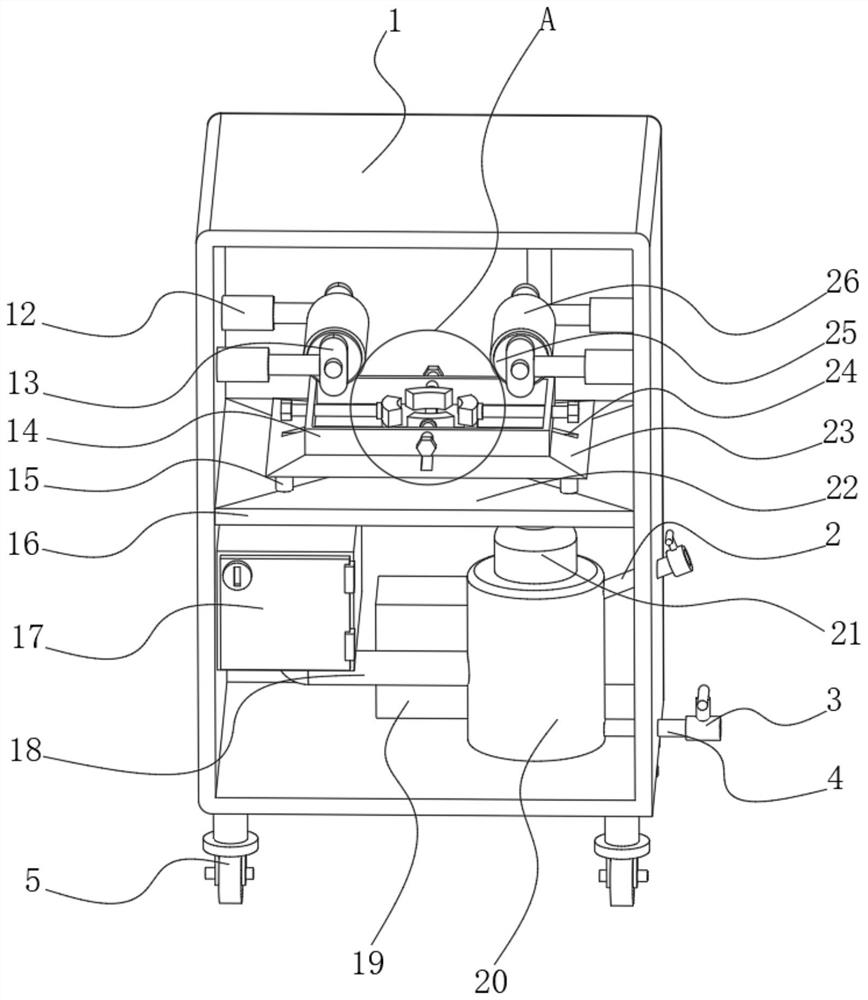

[0041] see Figure 1-7 , the present invention provides a technical solution: a semi-automatic mold polishing device capable of preventing flying debris, comprising a box body 1, a bottom box door 6 is movably installed on the bottom of the front side of the box body 1, and a top box door 6 is movably installed on the front side of the box body 1. Box door 8, the internal activity of top box door 8 is equipped with observation window 9, and the outside of top box door 8 is equipped with operation button 7, and the inside of box body 1 is fixedly installed with support plate 16, and the top of support plate 16 is hinged with four A pillar 15, the tops of the four pillars 15 are hinged with a swash plate 23, the inside of the swash plate 23 is provided with a cross chute 24, and the inside of the cross chute 24 is movably equipped with four slide blocks 32, and the tops of the four slide blocks 32 Both are fixedly installed with a soft ring plate 30, the opposite side of the sof...

Embodiment 2

[0044] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the cross chute 24 extends to the outside of the swash plate 23, the adjusting bolt 29 hinges through the limit frame 14 and extends to the outside of the limit frame 14, Both output ends of the double-head motor 25 are hingedly mounted inside the limiting plate 13 , and the polishing roller sleeve 26 is sleeved on the outside of the double-head motor 25 .

[0045] In this embodiment, open the top box door 8, put the mold that needs to be polished into the opposite side of the soft ring plate 30, and rotate the adjusting bolt 29 under the condition of the hinge limit force of the limit frame 14 on the shaft. The seat 31 is rotated inside, and the soft ring plate 30 is pushed inwardly under the action of the bottom slider 32 sliding in the cross chute 24 to clamp the mold, and the double-head motor 25 rotates to drive the outer polishing roller sleeve 26 to ro...

Embodiment 3

[0047] Such as Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the top of the support plate 16 is provided with a diversion groove 22, and the diversion pipe 11 is connected to the output end of the diversion groove 22, Quartz sand filter plates 33 are installed in the internal activities of the two groups of blocks 36, semi-permeable membrane filter plates 35 are installed in the internal activities of the two groups of blocks 36, the water storage tank 20 is fixedly installed at the bottom of the inner cavity of the box body 1, the drain 4 and the water inlet pipe 2 run through the outer side of the box body 1, and a water valve 3 is movably installed, and the end of the communication pipe 37 away from the water pump 21 is connected to the atomizer 28, and the communication pipe 37 runs through the support plate 16 and extends to the input end of the atomizer 28 , the atomizer 28 is fixedly installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com