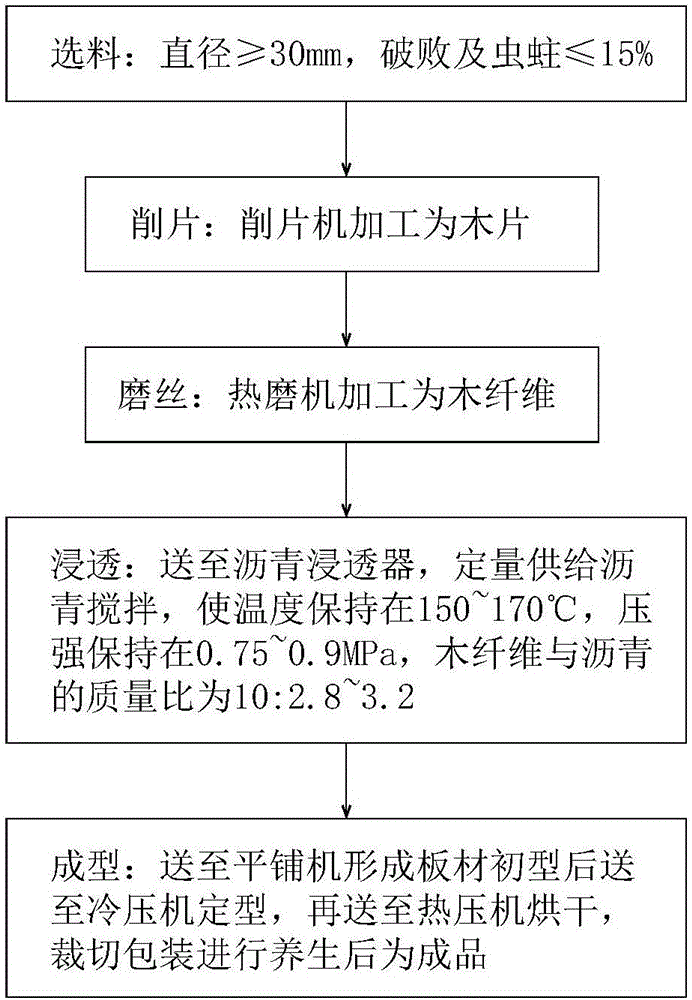

Pitch-wood-wool plate production process

A production process and asphalt wood technology, applied in wood processing appliances, wood treatment, impregnated wood, etc., can solve the problems of easy decay and deterioration, and easy aging of asphalt wood wool boards, so as to reduce labor costs and construction difficulties, and eliminate potential hidden dangers. , the effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

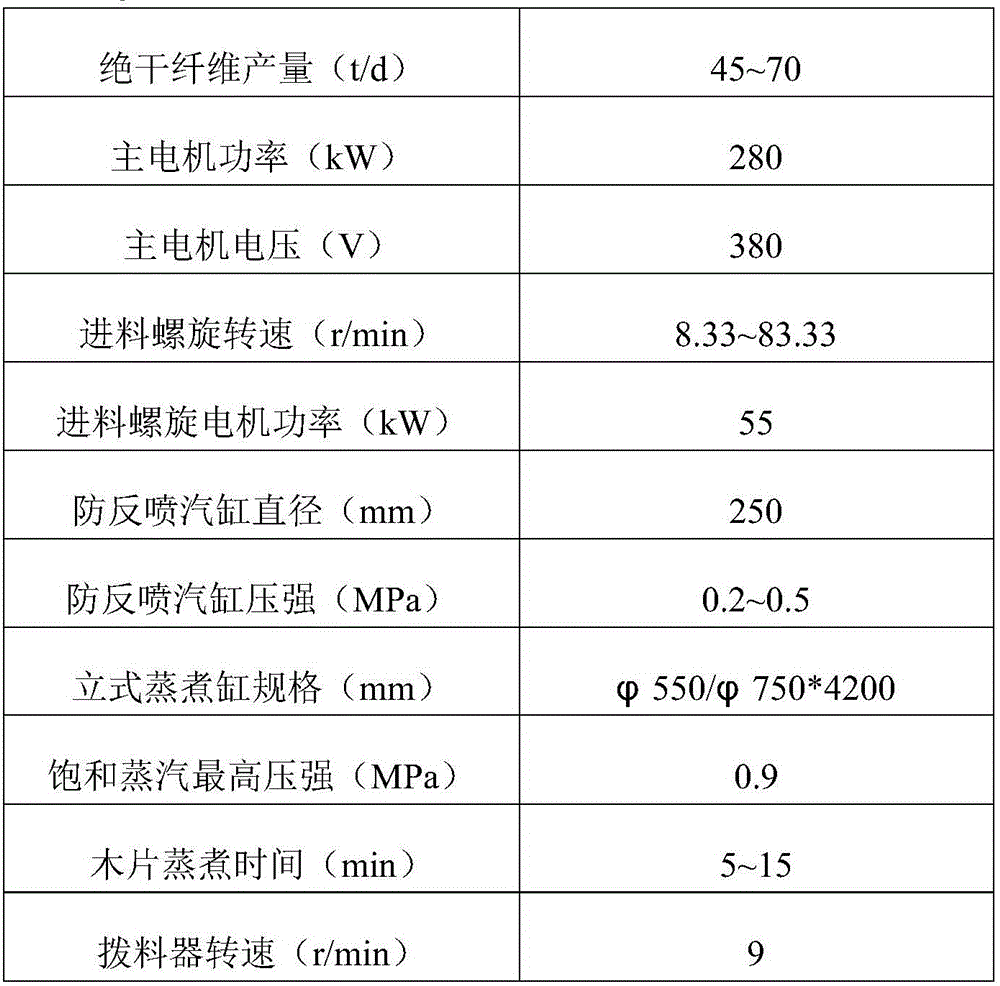

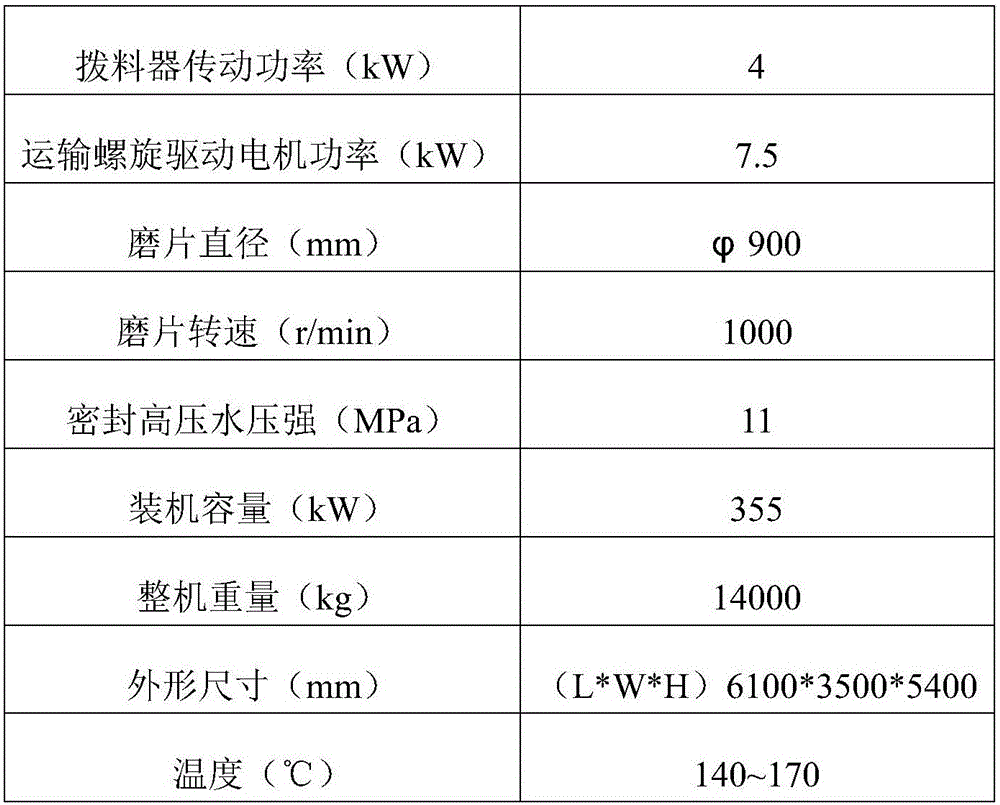

Method used

Image

Examples

Embodiment 1

[0046] In the soaking step, the stirring and mixing temperature is 150° C., the pressure is 0.75 MPa, the mass ratio of wood fiber to pitch is 10:2.8, and the rest are the same as above.

Embodiment 2

[0048] In the soaking step, the stirring and mixing temperature is 150°C, the pressure is 0.75MPa, the mass ratio of wood fiber to pitch is 10:3, and the rest are the same as above.

Embodiment 3

[0050] In the soaking step, the stirring and mixing temperature is 150° C., the pressure is 0.75 MPa, the mass ratio of wood fiber to pitch is 10:3.2, and the rest are the same as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com