Clay crucible forming machine

A clay crucible and molding machine technology, used in ceramic molding machines, molding indenters, molds, etc., can solve the problems of difficult to increase the genuine product rate, poor economic benefits, perforation, etc., to ensure product quality, reduce production costs, use and install handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

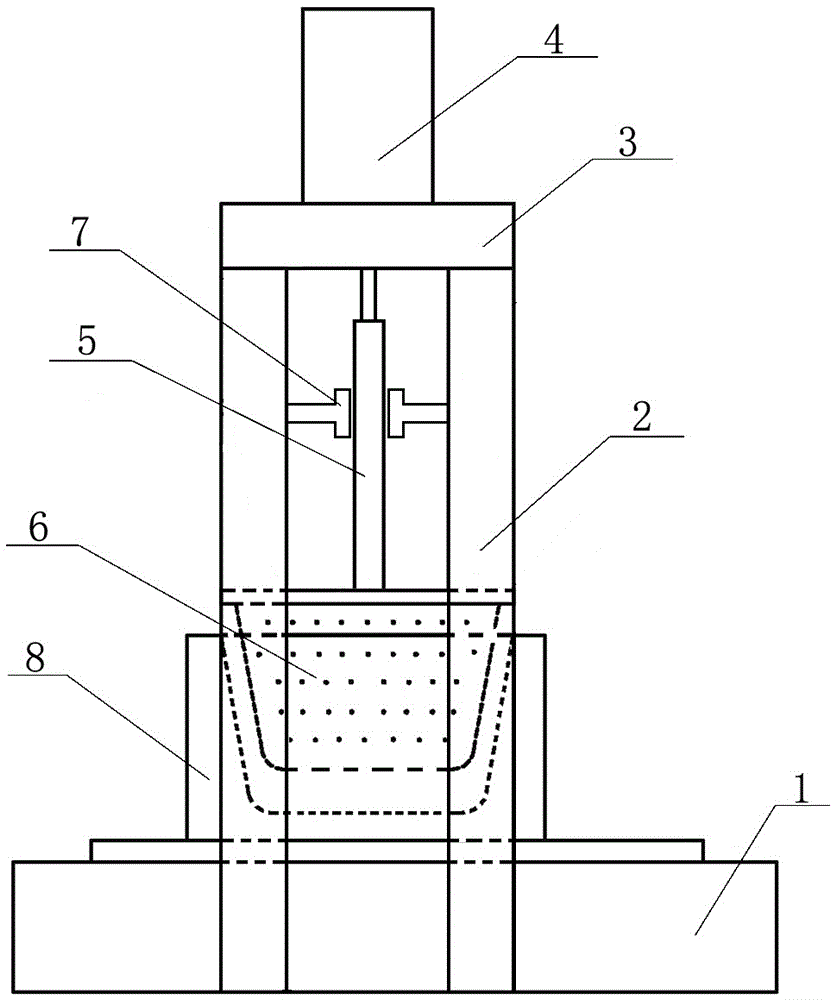

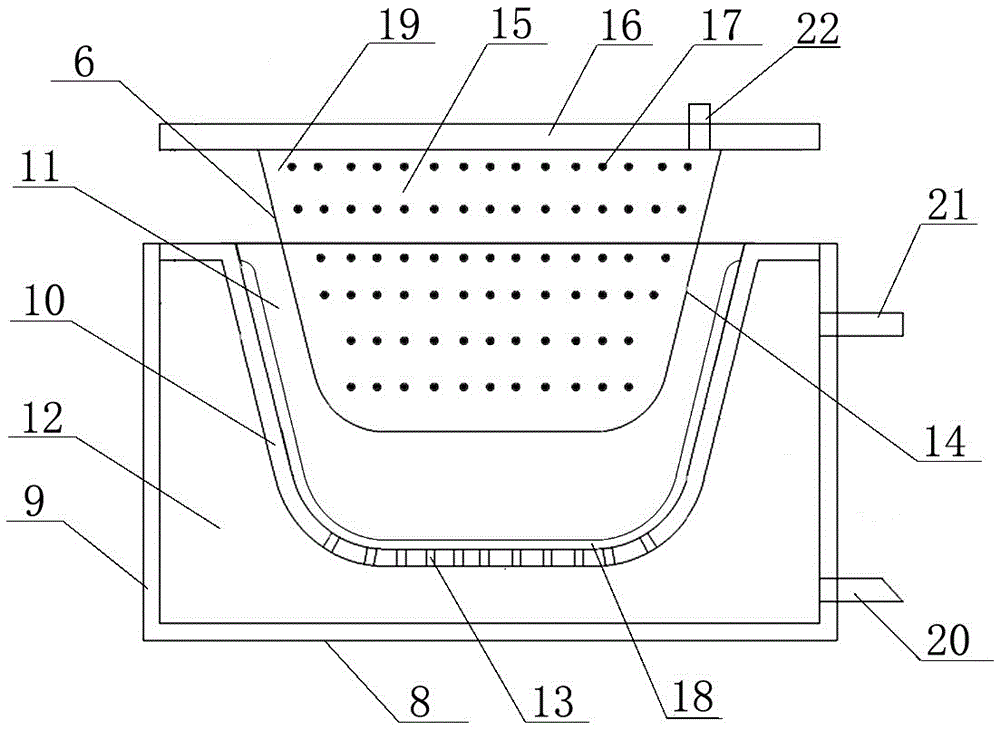

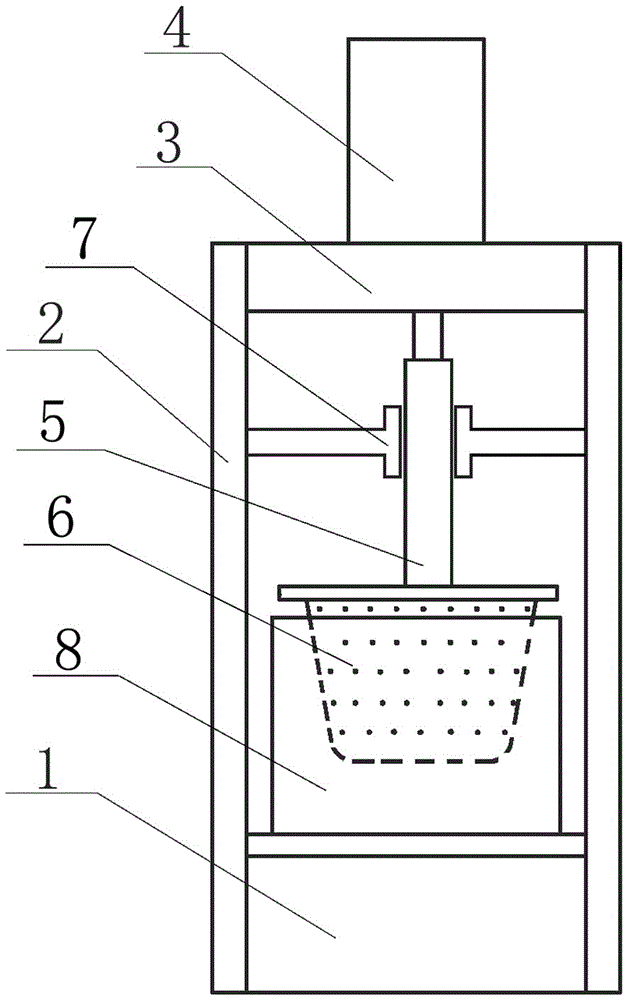

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 , 2 As shown, a clay crucible forming machine according to the present invention includes a frame provided with a working platform 1, and two vertically arranged columns 2 or a piece of Plate frame, the upper end of the column 2 or the plate frame is connected with a horizontal support plate 3, and constitutes an N-shaped support body; an oil cylinder 4 is installed on the horizontal support plate 3, and the piston of the oil cylinder 4 is vertically downward and A upper mold 6 that moves up and down is connected by a pressing rod 5, and the described pressing rod 5 is sleeved in a guide sleeve 7 that is transversely fixed on the N-shaped support body; on the working platform 1 below the upper mold 6 A lower die 8 matched with the upper die 6 is arranged, and the periphery of the lower die 8 is respectively fixedly connected with the four columns 2 or two pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com