Lightweight, low-cost and impact-resistant laminated prepreg composite board

A technology of impact resistance and composite panels, applied in the direction of synthetic resin layered products, layered products, glass/slag layered products, etc., can solve problems such as inability to obtain reinforcement effects, material stress concentration, and reduced impact strength. Achieve the effects of strong adhesion, low equipment investment, and overall cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

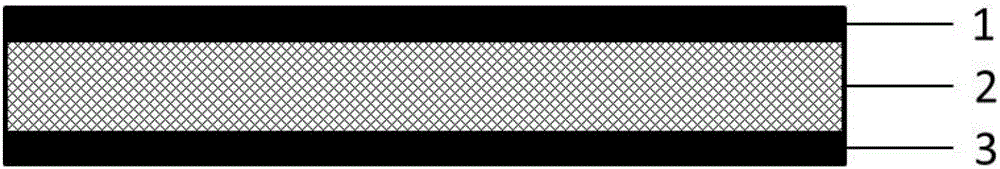

[0027] The upper skin 1 of the prepreg is a composite material of chopped glass fiber reinforced thermoplastic resin, the weight ratio of glass fiber to thermoplastic resin is 4:6, and the grammage is 350g / m 2 . The length of the chopped glass fiber is 25mm, and it has a network cross structure in the thermoplastic resin. The thermoplastic resin is a modified polypropylene film with a melt index of 50g / 10min and a weight of 105g / m 2 . The structure and grammage of the lower skin 3 of the prepreg are the same as those of the lower skin 3 of the prepreg. The core material 2 is a composite material of chopped glass fiber reinforced thermoplastic resin, and its structure and grammage are the same as those of the prepreg upper skin 1 .

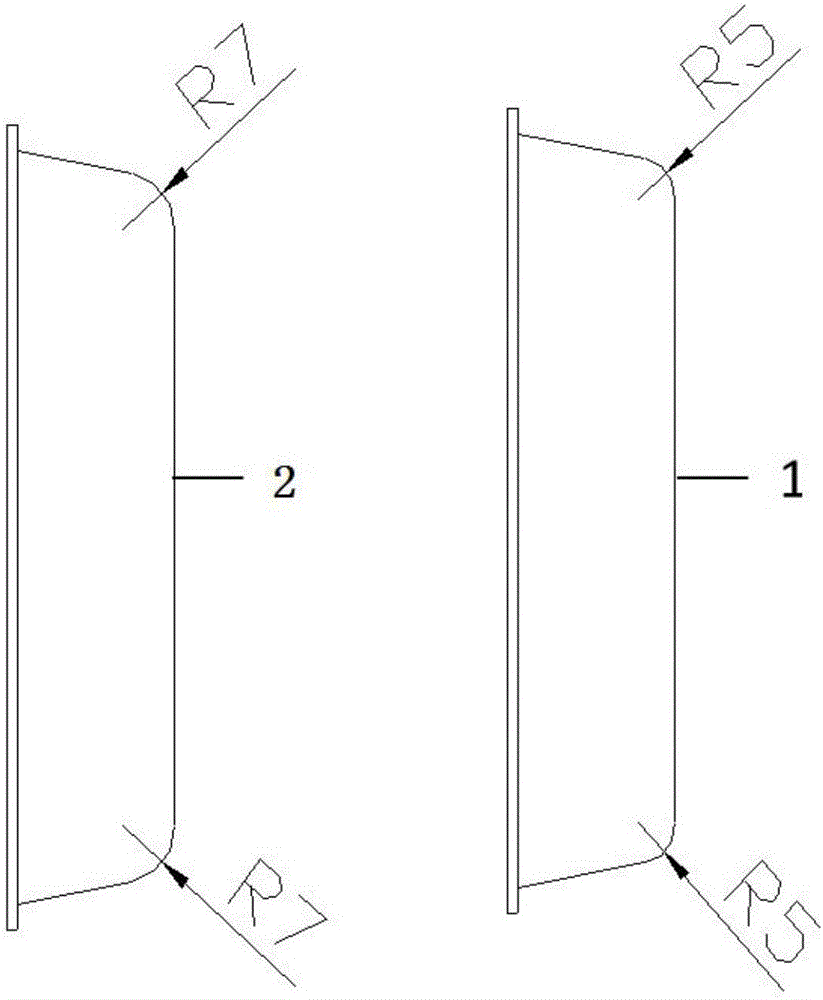

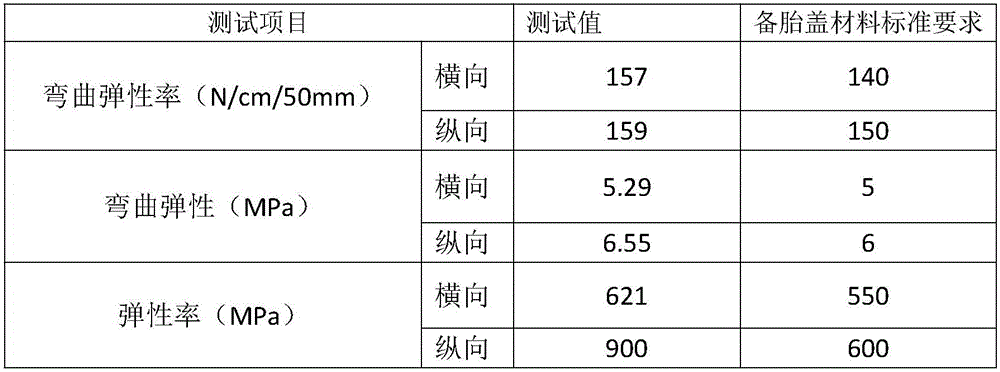

[0028] Press the upper three layers of materials together with a compound machine to form a 1050g / m 2 The laminated prepreg composite board can be used for the skin of the car interior material floor, spare tire cover and other materials, and ca...

Embodiment 2

[0033] The upper skin 1 of the prepreg is a composite material of chopped glass fiber reinforced thermoplastic resin, the weight ratio of glass fiber to thermoplastic resin is 6:4, and the grammage is 350g / m 2 . The length of the chopped glass fiber is 100mm, and it has a network cross structure in the thermoplastic resin. The thermoplastic resin is a modified polypropylene film, the melt index is 100g / 10min, and the weight is 70g / m 2 . The structure and grammage of the lower skin 3 of the prepreg are the same as those of the lower skin 3 of the prepreg. Core material 2 is unidirectional long-fiber prepreg, with a sheet weight of 350g / m 2 .

[0034] Press the upper three layers of materials together with a compound machine to form a 1050g / m 2 laminated prepreg composite panels. It can be used for the skin of the polypropylene honeycomb panel, which is the material of the truck compartment, and can play a reinforcing role.

Embodiment 3

[0036] The material and structure of the upper and lower skin layers in Example 3 are the same as in Example 1, except for the core layer: the core material 2 is grid glass fiber cloth, and the weight of a single sheet is 350g / m 2 .

[0037] Press the upper three layers of materials together with a compound machine to form a 1050g / m 2 laminated prepreg composite panels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com