A method for preparing anhydrous calcium sulfate filler with phosphogypsum

A technology of anhydrous calcium sulfate and phosphogypsum, applied in chemical instruments and methods, calcium/strontium/barium sulfate, inorganic chemistry, etc., can solve the problems of low technical content and low added value of products, and achieve broad industrial application prospects , good economic benefits, and the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

[0033] This example is to provide a preparation method of "Double 90" anhydrous calcium sulfate filler with high raw material utilization rate, simple process and high purity.

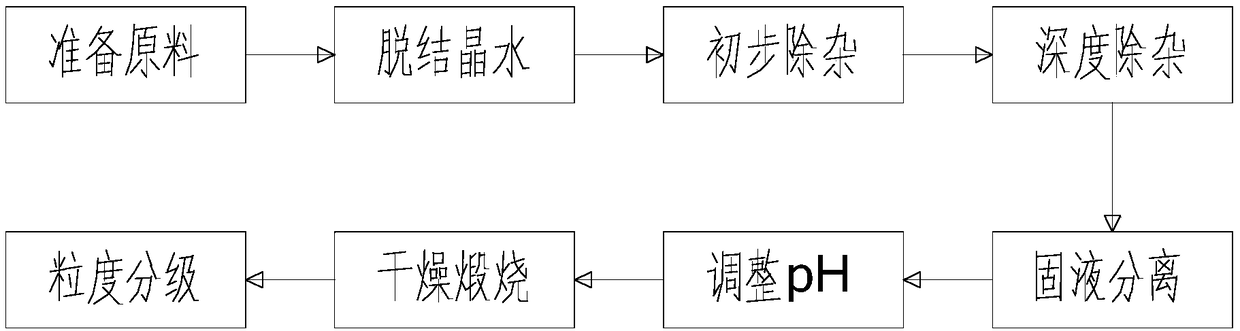

[0034] Such as figure 1 As shown, the method includes the following steps: preparing raw materials, decrystallization water, preliminary impurity removal reaction, deep impurity removal reaction, solid-liquid separation, pH adjustment, drying and calcination and particle size classification;

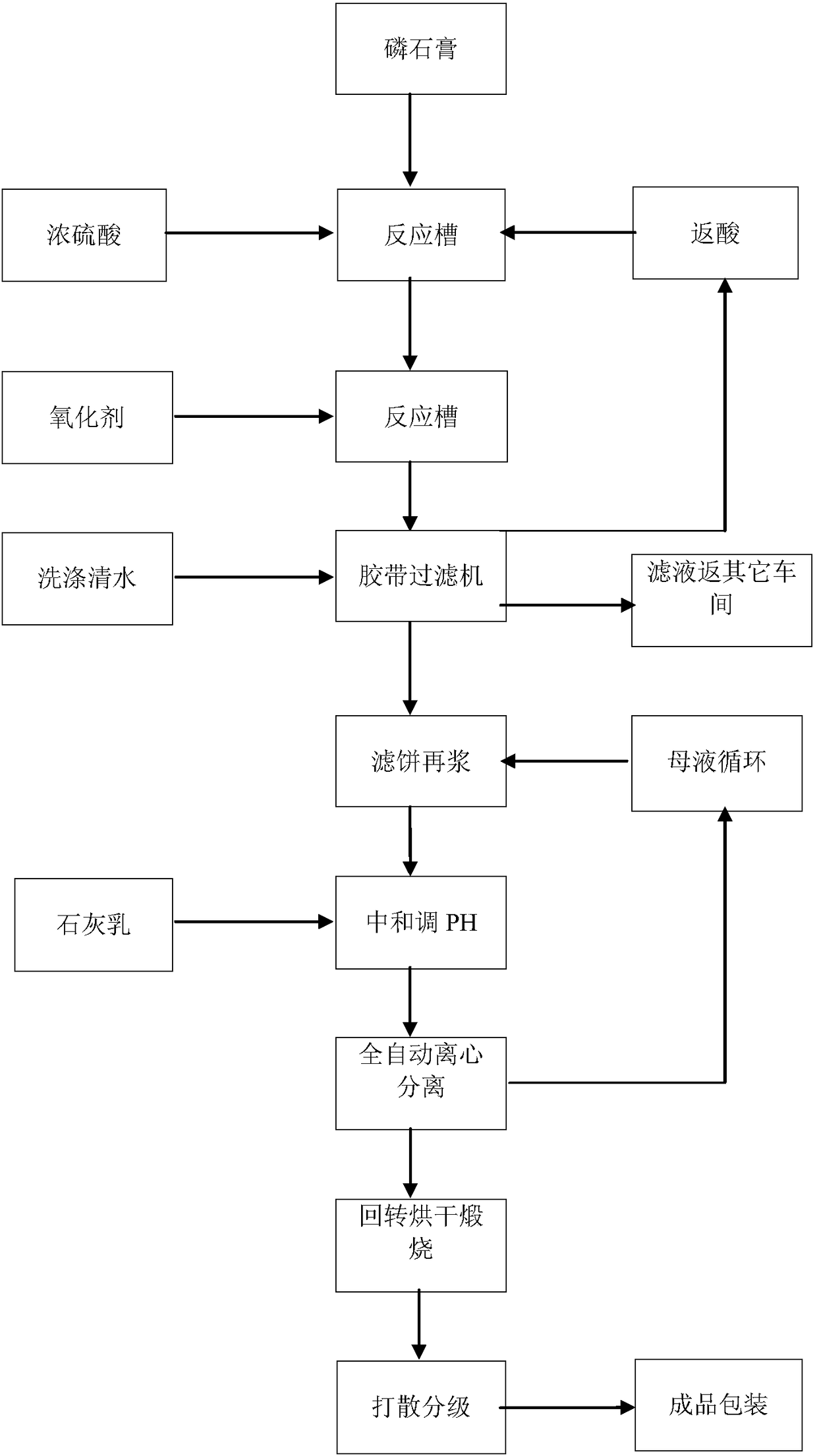

[0035] Such as figure 2 As shown, the specific steps of this method are as follows:

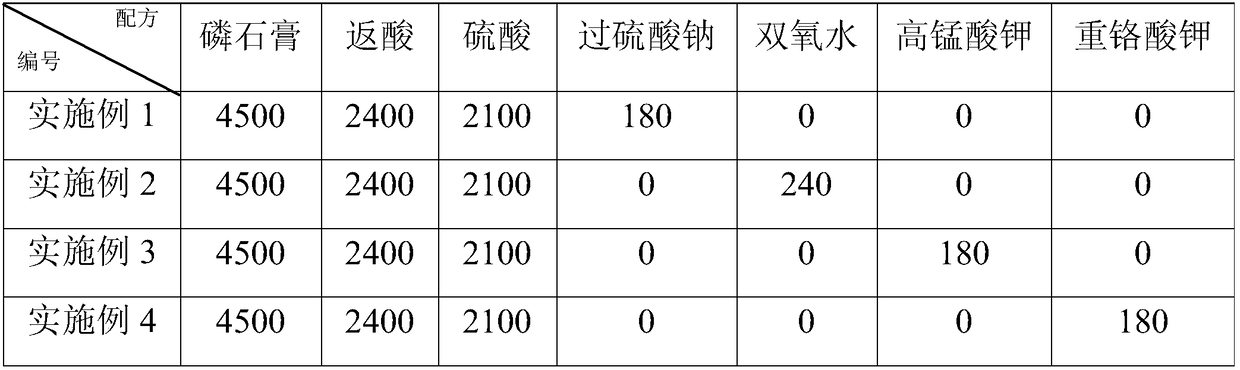

[0036] (1) The following raw materials are taken in parts by weight: 200-220 phosphogypsum with a free water rate of 21.8%, 80-100 concentrated sulfuric acid with a mass concentration of not less than 95%, and 5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com