Preparation method of fiber and cold patch asphalt mixture

A technology of cold patching asphalt and mixture, applied in the field of road repairing materials, can solve the problems of short service life, peeling, high cost, etc., achieve excellent low temperature crack resistance, improve fatigue life, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

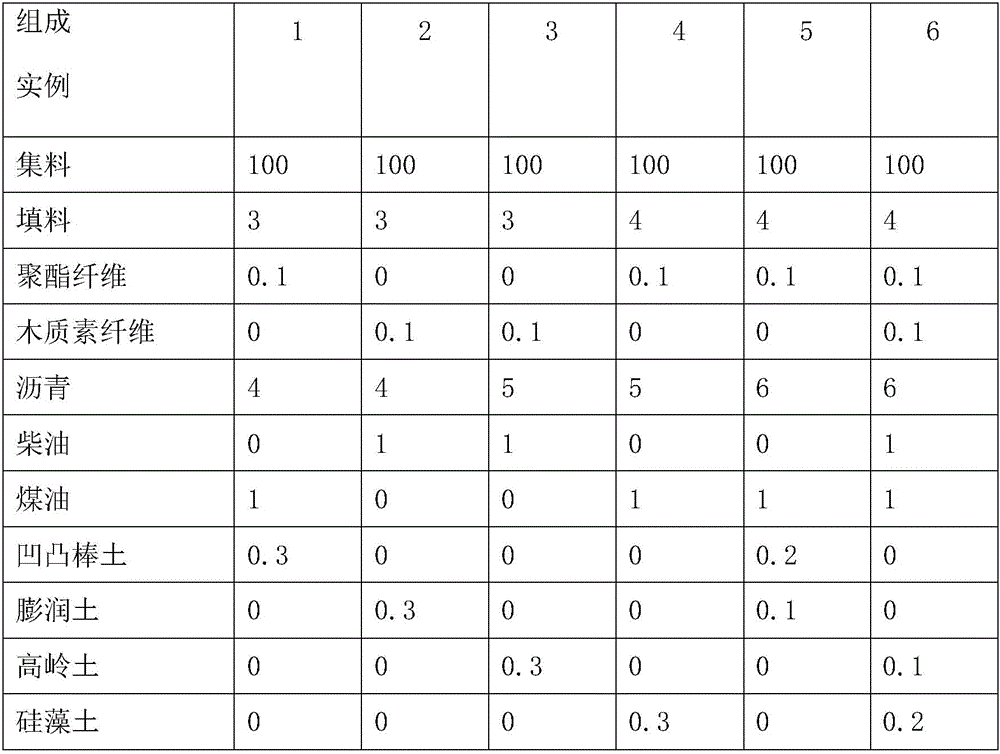

[0018] In order to illustrate the present invention better, further elaborate below in conjunction with example, but content of the present invention is not only limited to following example. Table 1 is the composition mass ratio of 6 embodiments.

[0019] Table 1 Mass ratio of cold-patch asphalt mixture

[0020]

[0021] The aggregate used in the above 6 examples is basalt, the asphalt is 70# matrix asphalt, and the filler is limestone. Examples 1-3 were graded as LB-16, and Examples 4-6 were graded as LB-13.

[0022] It needs to be explained that in addition to limestone powder, cement or fly ash can also be used as a filler. The above two fillers can also have similar effects, so we will not introduce them in detail here.

[0023] The preparation method of the fiber cold patch asphalt mixture of above-mentioned embodiment 1-6, it comprises the steps:

[0024] (1) carry out batching as shown in table 1;

[0025] (2) Mix the aggregate and filler evenly;

[0026] (3) H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com