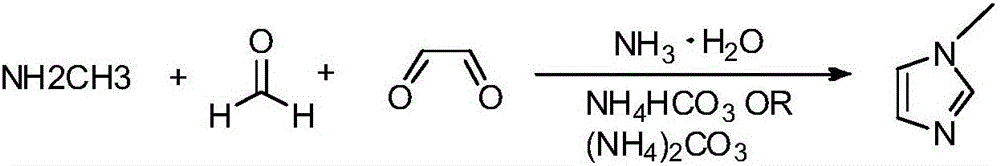

Method for preparing 1-methylimidazole

A technology of methyl imidazole and methylamine, applied in the field of chemical synthesis, can solve the problems of high amine dosage and low yield, and achieve the effects of improving yield, reducing production cost and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Drop into 40% 1-methylamine 280g and 20% ammoniacal liquor 300g and 40g ammonium bicarbonate in the three-necked flask of 2L, water-bath is warmed up to 40~45 ℃, drop by 40% glyoxal 500g and 37% 278g of formaldehyde is configured as a mixed aldehyde. After the dropwise addition is completed, it is raised to 50°C for 2 hours. After the heat preservation is completed, the reaction solution is concentrated and then rectified. Under a vacuum of 4.0KPa, collect 100 ~ The fraction at 110°C yielded 220 g of 1-methylimidazole, with a yield of 78%.

Embodiment 2

[0026] Drop into 40% 1-methylamine 280g and 20% ammoniacal liquor 300g and 25g ammonium carbonate in the three-necked flask of 2L, water-bath is warming up to 40~45 ℃, drop by 40% glyoxal 500g and 37 % of 278g of formaldehyde is configured as a mixed aldehyde. After the dropwise addition is completed, it is raised to 50°C for 2 hours. After the heat preservation is completed, the reaction solution is concentrated and then rectified. Under a vacuum of 4.0KPa, collect 100-110 ℃ fraction, 225g of 1-methylimidazole product was obtained, and the yield was 79.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com