Production method of N-cyclohexyl-2-benzothiazole sulfenamide

The technology of a benzothiazole sulfenamide and a production method is applied in the field of production and preparation of N-cyclohexyl-2-benzothiazole sulfenamide, and can solve the problem of affecting the generation rate, target N-cyclohexyl-2-benzene Problems such as the reduction of the generation rate of the thiazole sulfenamide and the reduction of the usable amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

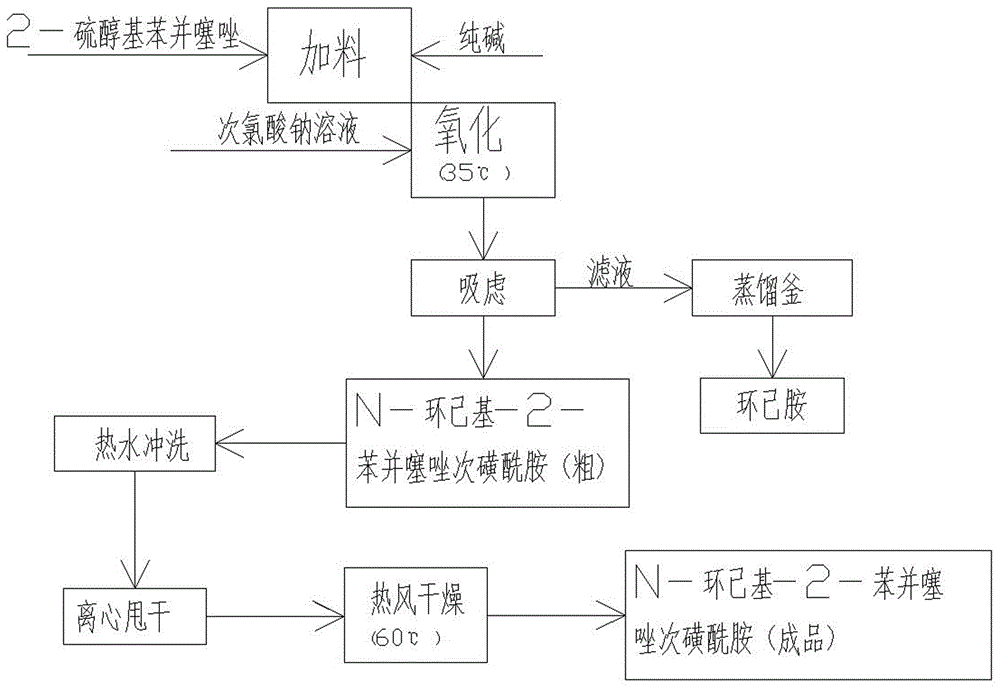

[0032] Such as figure 1 The shown production method of N-cyclohexyl-2-benzothiazole sulfenamide includes the following steps:

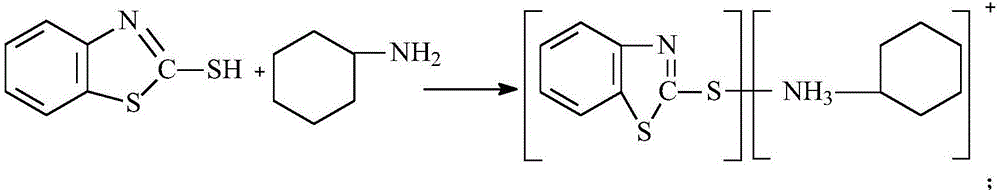

[0033] Step 1: Feeding: Add 16% cyclohexylamine in the oxidation tank, stir the cyclohexylamine solution and add 2-mercaptobenzothiazole to form a mixed solution, cyclohexylamine and 2-mercaptobenzothiazole The amine ratio is 2.3;

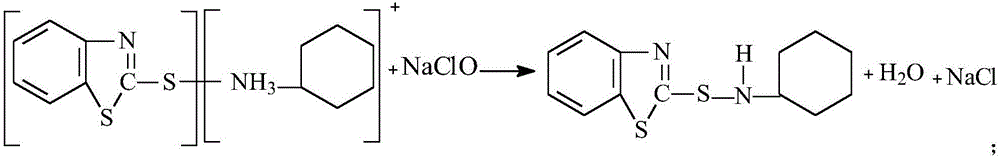

[0034] Step 2: Oxidation: Stir the mixture thoroughly, then cool it to 35°C, and slowly drop a 5% sodium hypochlorite solution into the mixture to form a reaction solution until there is N-cyclohexyl-2-benzothiazole sulfenic acid The amide is formed and the yellow particles of 2-thiol benzothiazole in the reaction solution disappear;

[0035] Step 3: Stir the oxidized reaction solution and pour it into a suction filter tank for filtration. The filtered N-cyclohexyl-2-benzothiazole sulfenamide is washed with hot water to neutrality, then centrifuged to dry and used The finished product of N-cyclohexyl-2-benzothiazole sulfenamid...

Embodiment 2

[0037] The difference between Example 2 and Example 1 is that the concentration of cyclohexylamine added in step 1 is 15%.

Embodiment 3

[0039] The difference between Example 3 and Example 1 is that the concentration of cyclohexylamine added in step 1 is 17%.

[0040] Compared with the methods commonly used in the market, the production method of the present invention can significantly increase the formation of N-cyclohexyl-2-benzothiazole sulfenamide under the same dosage of 2-thiol benzothiazole. At the same time, it reduces the dosage of cyclohexylamine. Meanwhile, among the three embodiments, the first embodiment is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com