Preparation method of low molecular weight peptide in larva chrysomyiae

A technology of small molecular polypeptide and separation method, applied in the field of separation of traditional Chinese medicinal materials, can solve problems such as low extraction yield, achieve the effects of simple operation, good reproducibility, and avoidance of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

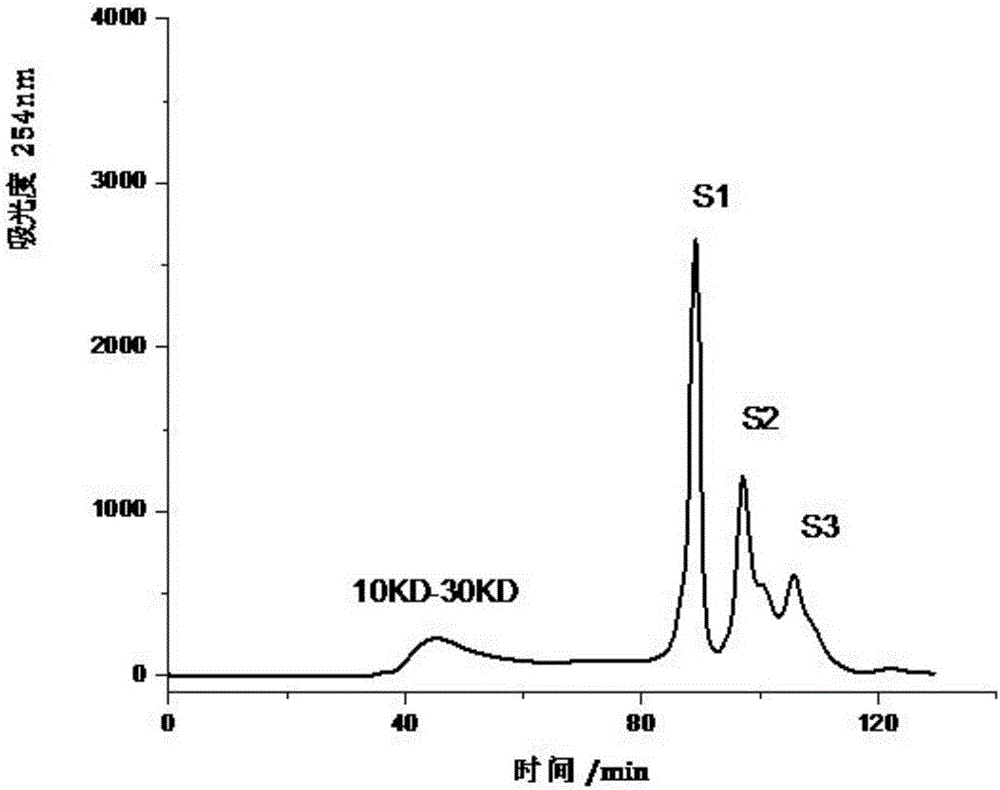

[0030] A. The preparation method of the small molecule polypeptide freeze-dried powder of grain worm:

[0031] 1) Homogenization: take freshly frozen grain worms, thaw and weigh them, add single distilled water 3 times the weight and volume of grain worms, and homogenize in a high-speed tissue homogenizer, and filter the homogenate with a 200-mesh gauze to obtain a filtrate;

[0032] 2) Ultrasonic crushing: Ultrasonic crushing of the filtrate for 40s, repeated 5 times, intensity 14kHz, 800W;

[0033] 3) Centrifugal filtration: Centrifuge the ultrasonically treated sample at 4°C and 12000rpm / min for 25min, take the supernatant, filter it with absorbent cotton to remove the fat in the uppermost layer, repeat this step twice to obtain the filtrate;

[0034] 4) Heating in a water bath: heat the filtrate in a water bath at 90°C while stirring for 12 minutes to remove macromolecular proteins;

[0035] 5) Take the supernatant by centrifugation: after heating the filtrate in a water ...

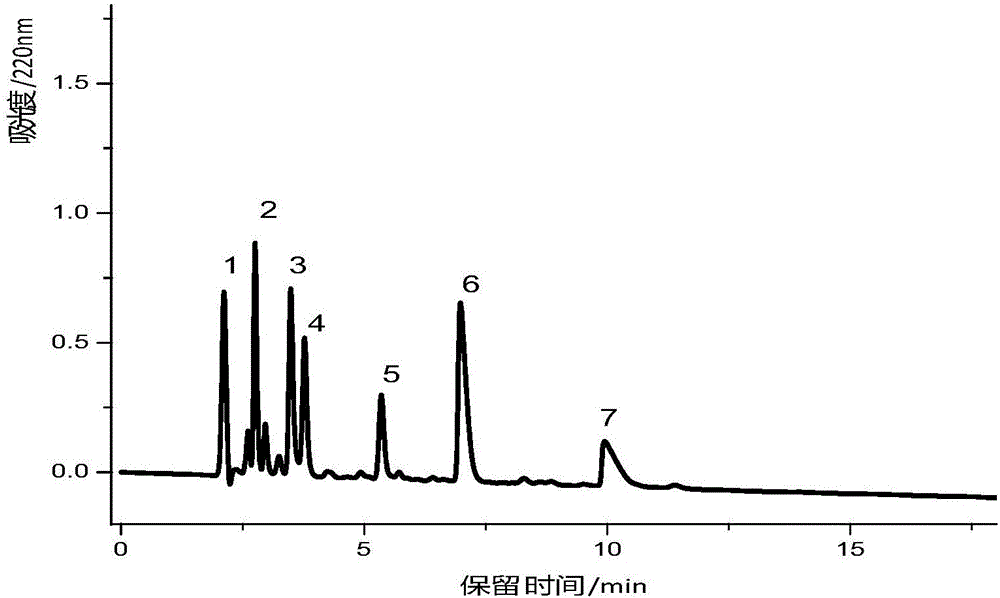

Embodiment 2

[0061] A. The preparation method of the small molecule polypeptide freeze-dried powder of grain worm:

[0062] 1) Homogenization: take freshly frozen grain worms, thaw and weigh them, add single-distilled water twice the weight and volume of grain worms, and homogenize in a high-speed tissue homogenizer, and filter the homogenate with a 200-mesh gauze to obtain a filtrate;

[0063] 2) Ultrasonic crushing: Ultrasonic crushing of the filtrate for 30s, repeated 4 times, intensity 14kHz, 600W;

[0064] 3) Centrifugal filtration: centrifuge the ultrasonically treated sample at 4°C and 10,000 rpm / min for 25 minutes, take the supernatant, filter it with absorbent cotton to remove the uppermost layer of fat, repeat this step twice to obtain the filtrate;

[0065] 4) Heating in a water bath: heat the filtrate in a water bath at 100°C while stirring for 12 minutes to remove macromolecular proteins;

[0066] 5) Take the supernatant by centrifugation: after heating the filtrate in a wate...

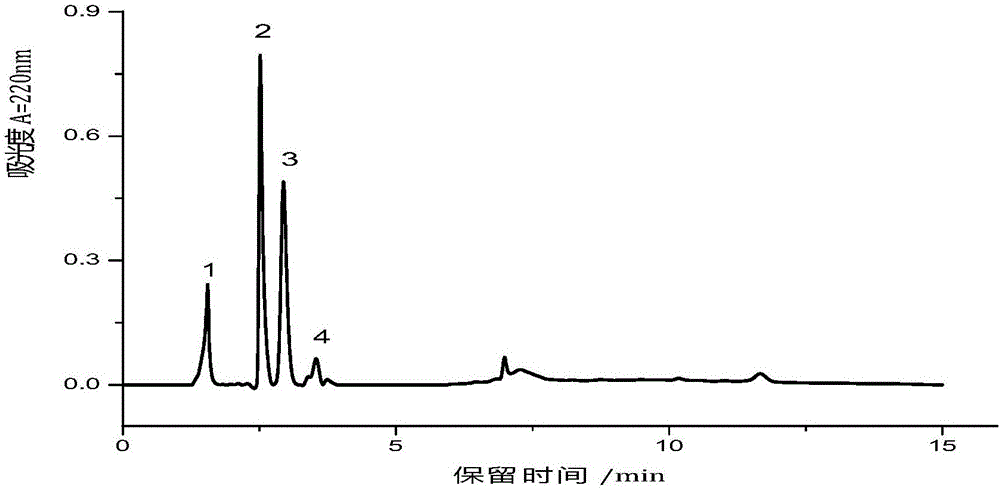

Embodiment 3

[0093] A. Preparation method of small molecule polypeptide freeze-dried powder of grain worm:

[0094] 1) Homogenization: take freshly frozen grain worms, thaw and weigh them, add single distilled water 4 times the weight and volume of grain worms, and homogenize in a high-speed tissue homogenizer, and filter the homogenate with a 200-mesh gauze to obtain a filtrate;

[0095] 2) Ultrasonic crushing: Ultrasonic crushing of the filtrate for 50s, repeated 6 times, intensity 16kHz, 800W;

[0096] 3) Centrifugal filtration: Centrifuge the ultrasonically treated sample at 4°C and 12000rpm / min for 25min, take the supernatant, filter it with absorbent cotton to remove the fat in the uppermost layer, repeat this step twice to obtain the filtrate;

[0097] 4) Heating in a water bath: heat the filtrate in a water bath at 100°C while stirring for 12 minutes to remove macromolecular proteins;

[0098]5) Take the supernatant by centrifugation: after heating the filtrate in a water bath, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com