Polyaniline graphene anti-corrosion coating and preparation method thereof

An anti-corrosion coating, graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of increased wear resistance, anti-corrosion performance needs further research, etc., to achieve difficult deposition and sag, anti-corrosion performance High and strong sealing performance

Inactive Publication Date: 2017-02-22

ZHONGSHAN MOORE CHEM IND CO LTD

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Some researchers used graphene as raw material to prepare polyaniline graphene composite materials. After adding it to the anti-corrosion coating system, the comprehensive performance of the coating film was greatly improved. If the required coating thickness was reduced, the coating adhesion and wear resistance increased, but Its anti-corrosion performance needs further study

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~3

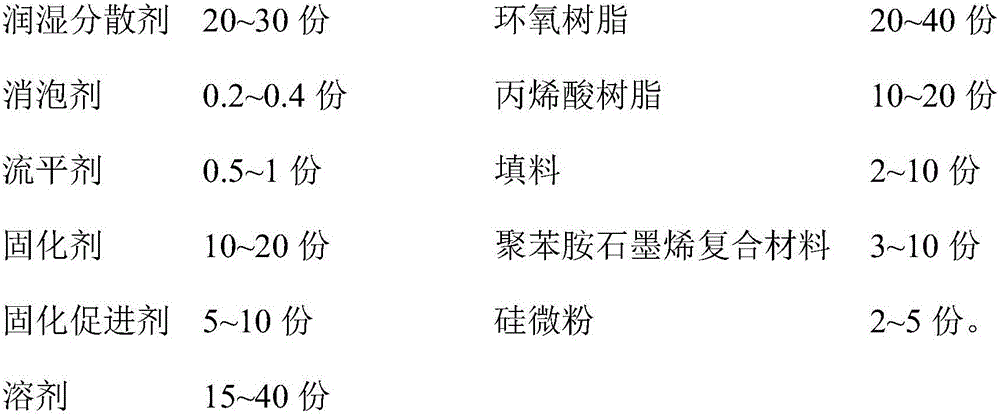

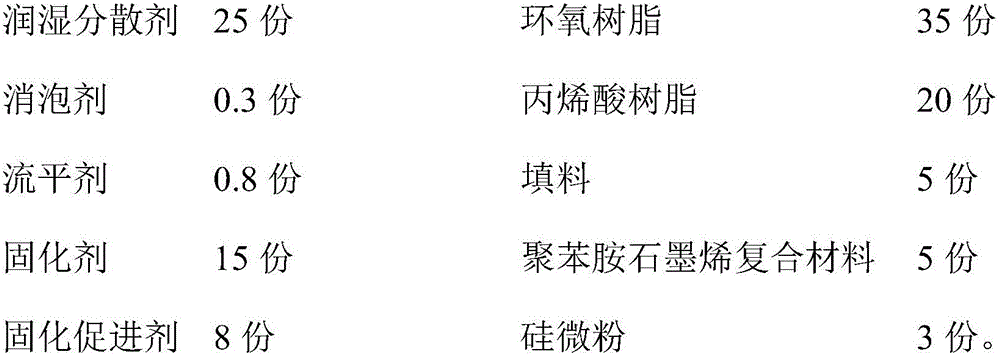

[0045] Embodiment 1~3 discloses a kind of polyaniline graphene anticorrosion coating, and its component and weight part thereof are as shown in table 1:

[0046] The composition distribution ratio of table 1 embodiment 1~3

[0047]

[0048]

[0049] With the preparation method in the specific embodiment, obtain polyaniline graphene anticorrosion coating.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a polyaniline graphene anti-corrosion coating and a preparation method thereof. The polyaniline graphene anti-corrosion coating comprises a wetting dispersant, a defoaming agent, a leveling agent, a curing agent, a curing accelerator, a solvent, epoxy resin, acrylic resin, a filler, a polyaniline graphene composite material and silicon micro-powder. The preparation method includes the steps: 1) pouring the epoxy resin and the solvent into a ball-milling tank and uniformly mixing the epoxy resin and the solvent to obtain a mixed solution; 2) adding the filler, the polyaniline graphene composite material and the silicon micro-powder into the mixed solution, grinding the mixed solution and then adding the curing agent and the curing accelerator to obtain grinding fluid; 3) adding the wetting dispersant, the defoaming agent, the leveling agent and the acrylic resin into the grinding fluid, uniformly stirring and mixing the wetting dispersant, the defoaming agent, the leveling agent, the acrylic resin and the grinding fluid to obtain the polyaniline graphene anti-corrosion coating. The anti-corrosion coating has good insulating property and durability, is beneficial to resisting physical damage to a film and excellent in comprehensive performance, and achieves an anti-corrosion function.

Description

technical field [0001] The invention relates to a polyaniline graphene anticorrosion coating and a preparation method thereof, belonging to the technical field of architectural coatings. Background technique [0002] Metal materials are damaged by the action of the surrounding medium, which is called metal corrosion (Metallic Corrosion). Metal rusting is the most common form of corrosion. During corrosion, a chemical or electrochemical heterogeneous reaction occurs at the interface of the metal, turning the metal into an oxidized (ion) state. This will significantly reduce the mechanical properties of metal materials such as strength, plasticity, and toughness, destroy the geometry of metal components, increase wear between parts, deteriorate electrical and optical physical properties, and shorten the service life of equipment. Corrosion of metals is very common. Among them, the corrosion of iron products, the metal with the largest amount, is the most common. There are ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D163/00C09D133/00C09D5/08C09D7/12

CPCC09D163/00C08K2201/014C08L2205/035C09D5/08C09D7/61C09D7/65C08L33/00C08L79/02C08K13/02C08K3/04C08K3/36C08K2003/265

Inventor 黄宏亭桂玲黎司华余兵王海洋魏婷婷刘彬梁丽娟

Owner ZHONGSHAN MOORE CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com