Anti-fingerprint coating liquid and anti-fingerprint hardening film

An anti-fingerprint and coating liquid technology, applied in the field of materials, can solve the problems of easy residual fingerprints and surface contamination, and achieve the effect of improving smoothness, wear resistance and good hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

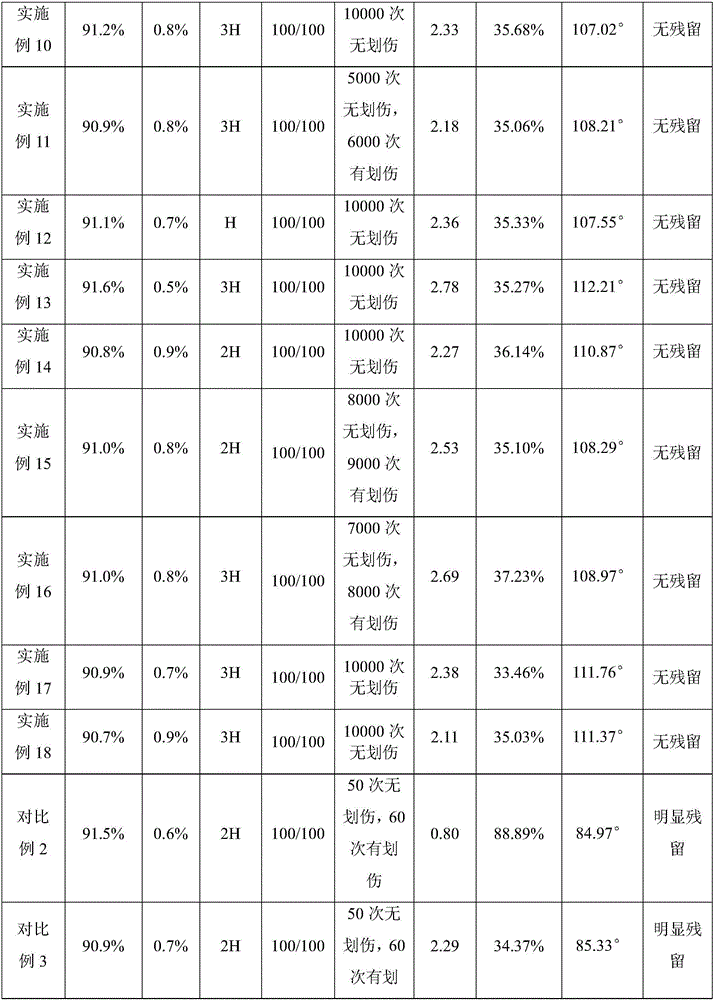

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned anti-fingerprint hardened film of the present invention may include the following steps: first, coating the anti-fingerprint hardened film on the surface of a substrate to form a hardened coating; then, performing photocuring on the above-mentioned hardened coating to obtain the above-mentioned anti-fingerprint Fingerprint hardening film. Those skilled in the art can set the process conditions of the above-mentioned coating process and photocuring treatment according to the existing technology. Before the anti-fingerprint hardened film is coated on the surface of the substrate, the above-mentioned preparation method may also include the step of diluting the anti-fingerprint coating solution, and the solid content of the anti-fingerprint coating solution after dilution is 20% to 50%, preferably 25% to 50%. 45%, more preferably 30-40%. Limiting the content of the organic solvent to the above preferred parameter range can enab...

Embodiment 1

[0042] The preparation method of the anti-fingerprint coating solution provided by the present embodiment comprises:

[0043] Mix 20 parts by weight of fluorine-containing acrylic acid prepolymer, 25 parts by weight of matrix resin, 5 parts by weight of photoinitiator and 50 parts by weight of organic solvent, wherein the fluorine-containing acrylic acid prepolymer is fluoromethacrylate butyl Ester, matrix resin is epoxy acrylic resin (Changxing chemical 621A-80), photoinitiator is 184 (manufacturer is BASF IRGACURE of Germany), and organic solvent is ethyl acetate.

Embodiment 2

[0045] The preparation method of the anti-fingerprint coating solution provided by the present embodiment comprises:

[0046] With 50 parts by weight of fluorine-containing acrylic prepolymer, 10 parts by weight of matrix resin, 1 part by weight of photoinitiator and 39 parts by weight of organic solvent, wherein the fluorine-containing acrylic prepolymer is fluorine-containing butyl methacrylate , matrix resin is epoxy acrylic resin, photoinitiator is 184 (manufacturer is BASF IRGACURE of Germany), and organic solvent is ethyl acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com