An integrated quantum dot synthesis method and device based on a microchannel ion pump

A quantum dot and microchannel technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve the problem of difficult distribution of precursor solutions, achieve controllable reactions and improve synthesis rates. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The above device was used to prepare the green perovskite quantum dot solution.

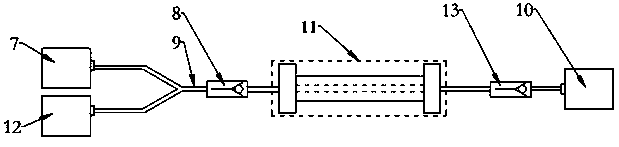

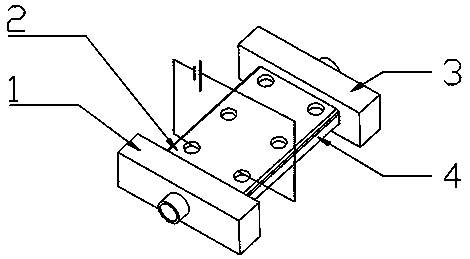

[0051] According to attached figure 1 The ion pump device is assembled as shown, and the device is connected to the precursor liquid container and the quantum dot collector according to the above connection method, and the reaction chamber of the device is placed in a temperature-controlled oil bath. Wherein the groove of the device micro-grooved corrugated plate 4 is V-shaped, the depth of the V-shaped groove is 2mm, and the top angle is 90°.

[0052] (1) Fully dissolve 0.2mmol of cesium bromide in 10ml of dimethylformamide (DMF), pour into the first precursor solution container 7; fully dissolve 0.2mmol of lead bromide in 10ml of DMF, and pour into the first precursor container 7; Two precursor liquid containers 12;

[0053] (2) Add 1ml of oleic acid (OA), 0.5ml of oleylamine (OAm) and 57.5mL of toluene to both the first precursor container 7 and the second precursor container 12. Pre...

Embodiment 2

[0059] According to attached figure 1 The ion pump device is assembled as shown, and the device is connected to the precursor liquid container and the quantum dot collector according to the above connection method, and the reaction chamber part of the device is placed in a temperature-controlled oil bath. Wherein the groove of the device micro-grooved corrugated plate 4 is a trapezoidal groove with a depth of 1 mm, the upper width of the trapezoid is 300 μm, and the lower width is 2 mm.

[0060] (1) Fully dissolve 0.2mmol of cesium bromide in 10ml of dimethylformamide (DMF), pour into the first precursor solution container 7; fully dissolve 0.2mmol of lead bromide in 10ml of DMF, and pour into the first precursor container 7; Two precursor liquid containers 12;

[0061] (2) Add 1ml of oleic acid (OA), 0.5ml of oleylamine (OAm) and 57.5mL of toluene to both the first precursor container 7 and the second precursor container 12. Precursor solution A and precursor solution B are...

Embodiment 3

[0067] According to attached figure 1 The ion pump device is assembled as shown, and the device is connected to the precursor liquid container and the quantum dot collector according to the above connection method, and the reaction chamber part of the device is placed in a temperature-controlled oil bath. Wherein the groove of the device micro-grooved corrugated plate 4 is a rectangular groove, the groove depth is 1mm, and the groove width is 1.5mm.

[0068] (1) Fully dissolve 0.2mmol of cesium bromide in 10ml of dimethylformamide (DMF), pour into the first precursor solution container 7; fully dissolve 0.2mmol of lead bromide in 10ml of DMF, and pour into the first precursor container 7; Two precursor liquid containers 12;

[0069] (2) Add 1ml of oleic acid (OA), 0.5ml of oleylamine (OAm) and 57.5mL of toluene to both the first precursor container 7 and the second precursor container 12. Precursor solution A and precursor solution B are respectively prepared in the containe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com