Iron-based alloy powder for laser refabrication of rotor journal, and refabrication method thereof

A laser remanufacturing, iron-based alloy technology, applied in metal material coating process, coating and other directions, can solve the problems of increasing the cost of replacing the rotor, difficult to install and use again, not meeting energy saving and consumption reduction, etc. Good oxidation performance, excellent quality, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The total mass of this batch of powder alloy is 5.7Kg, and its chemical composition (weight percentage) is C: 0.1%, Cr: 16.0%, Si: 1.5%, B: 1.0%, Fe: balance. The particle size of the powder after sieving is 40-140um.

[0047] An iron-based alloy powder used for laser remanufacturing of 28CrMoNiV rotor shaft journal is used as follows:

[0048] (1) Turn the failure part of the rotor journal first to make the surface clean, smooth and degrease;

[0049] (2) Put the dry powder into the powder feeder;

[0050] (3) Adjust the laser position to the area to be repaired, and edit the program.

[0051] (4) Set the laser process parameters as follows: laser power to 3.0KW, scanning speed to 4mm / s, powder feeding rate to 10g / min, laser spot diameter to 6mm, overlap rate to 50%, and laser cladding remanufacturing ;

[0052] (5) Repeat cladding multiple layers according to actual needs to exceed the target size and leave a machining allowance;

[0053] (6) Turning to the targe...

Embodiment 2

[0056] The total mass of this batch of powder alloy is 2.8Kg, and its chemical composition (weight percentage) is C: 0.03%, Cr: 13.0%, Si: 0.9%, B: 0.5%, Fe: balance. The particle size of the sieved powder is 40-140um.

[0057] The specific steps of the laser combined manufacturing process are as follows:

[0058] (1) to (5) are the same as the laser combination manufacturing process steps in Embodiment 1.

[0059] After machining, the portable hardness tester is used to test the average Vickers hardness of the repaired area is 307Hv. As the number of layers increases, the hardness will decrease. After 4 layers, the hardness will hardly change, and the hardness will drop to 286Hv at the lowest. , No cracks were found by coloring flaw detection.

Embodiment 3-7

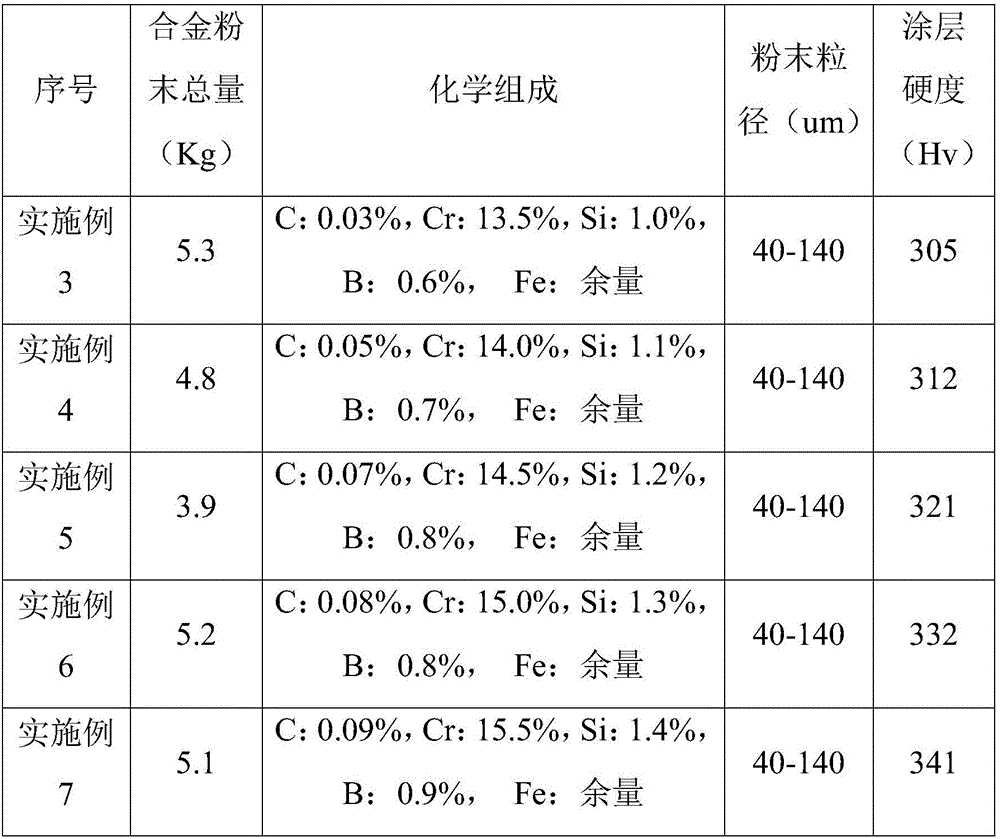

[0061] Implementation steps are with embodiment (1) and (2). The total amount, chemical composition, powder particle size and coating hardness of the batch of alloy powder are shown in Table 1.

[0062] Table 1 Examples 3-7

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com