Heat energy power system for liquid condensation

A power system and thermal energy technology, applied in steam/steam condensers, machines/engines, lighting and heating equipment, etc., can solve the problems of unstable medium pressure, low conversion efficiency of mechanical energy, and lower maximum efficiency of thermal energy, etc. efficiency and condensation efficiency, improve thermal energy conversion efficiency, and increase the effect of thermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

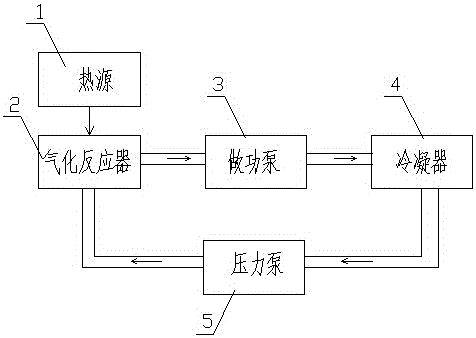

[0098] Embodiment one (such as figure 1 shown): a thermal power system for liquid condensation, including heat source 1, gasification reactor 2, work pump 3, condenser 4, pressure pump 5 and circulation pipeline 6, gasification reactor 2, work pump 3, condensation The device 4 and the pressure pump 5 realize circulation through the circulation pipe 6, and the gasification reactor 2 is in contact with the heat source 1;

[0099] As a specific description of the above implementation process, the heat source 1 adopts medium-high temperature gas.

[0100] As a specific description of the above implementation process, the gasification reactor 2 includes a layer of cavity 21; the cavity 21 is elliptical.

[0101] As a specific description of the above implementation process, the working pump 3 is an impeller working pump.

[0102] As a specific description of the above implementation process, the condenser 4 is an air-cooled condenser.

[0103] As a specific description of the ab...

Embodiment 2

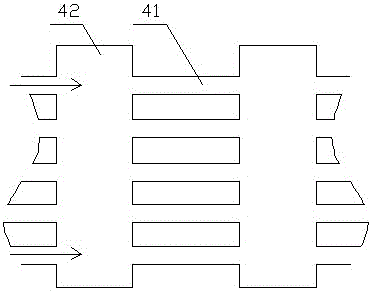

[0106] Embodiment two (such as figure 2 shown): The difference from Embodiment 1 is that the condenser 4 adopts a liquid cooling method, and the condenser 4 includes a condensation pipe 41 and four condensation chambers 42, and multiple condensation pipes are passed between the two condensation chambers 42 The pipe 41 is connected; the condensation pipe 41 is curved; the condensation pipe 41 is spiral.

[0107] With the above-mentioned structure, since the working medium in the condenser 4 undergoes multiple mixing and splitting, and has a large contact area with the outside world, the working medium can be separated from gas and liquid in the condensation chamber 42, which can effectively avoid incomplete condensation and reduce condensation. The pressure of the chamber 42 increases the amount of work done by the work pump 3, and at the same time increases the expansion ratio of the working fluid in the gasification reactor 2, thereby improving efficiency.

[0108]Experimen...

Embodiment 3

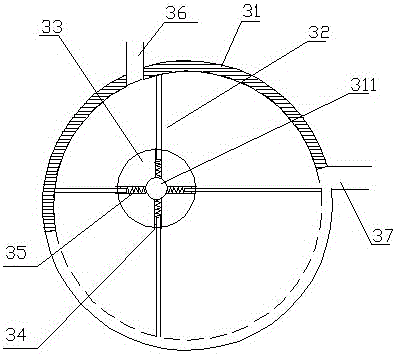

[0109] Embodiment three (such as image 3 shown): The difference from Embodiment 1 is that the working pump 3 includes a circular chamber 31, eccentric blades 32 and a grooved runner 33, and the grooved runner 33 is eccentrically installed on the eccentric shaft 311 of the circular chamber 31 Inside, the side of the grooved runner 33 is provided with a card slot 34, the eccentric blade 32 is installed in the card slot 34 through a spring leaf 35, and the sides of the circular cavity 31 are respectively provided with an air inlet 36 and an air outlet 37, and the air inlet The spacing angle between mouth 36 and air outlet 37 is greater than the spacing angle between adjacent two eccentric blades 32; The pitch angle between two adjacent eccentric blades 32; the eccentric blades 32 of the working pump 3 include four pieces.

[0110] Adopt above-mentioned structure, form isolated chamber between adjacent eccentric blades 32, and what communicate with air inlet 36 is expansion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com