Working condition control device in pump turbine speed adjusting system and control method of working condition control device

A technology of water pump turbine and speed control system, which is applied in the direction of speed control, safety device, control system use, etc., can solve the problems of insufficient protection of units and equipment, limited operating range and operating interval of units, and easily damaged equipment, etc., and achieves a simple structure. , low cost, the effect of expanding the operating range and scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

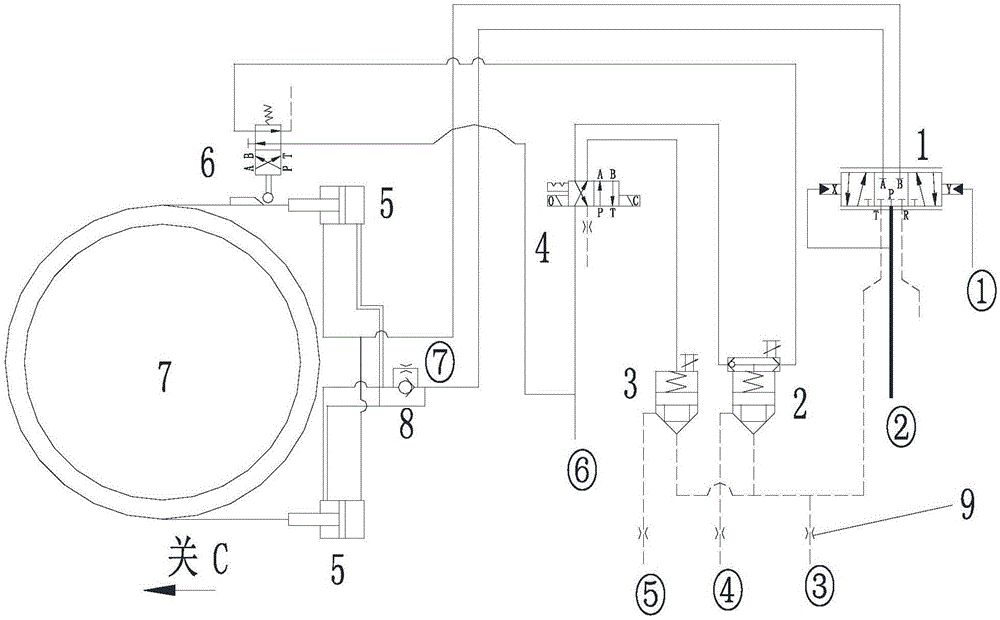

[0037] see figure 1 , the operating condition control device in the speed regulating system of the water pump and turbine in this embodiment includes a main pressure distribution valve 1, a shuttle valve cartridge valve group 2, a cartridge valve 3, a working condition selection valve 4, a servomotor 5, and a segmented closing valve group 6. Guide vane control ring 7, check valve 8, electro-hydraulic control oil input port ①, pressure oil input port ②, 3 throttle oil discharge ports (the first throttle oil discharge port ③, the second throttle oil discharge port Port ④, third throttle oil discharge port ⑤), control oil input port ⑥, throttle valve ⑦. According to the figure, the following describes the connection relationship of each component as follows.

[0038] The input end of the main pressure distribution valve 1 is respectively connected to the electro-hydraulic control oil input port ① and the pressure oil input port ② through pipelines, and the output end is respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com