A valveless reciprocating micropump

A main pipeline and elastic rod technology, applied in the field of microfluidics, can solve the problems of unsatisfactory micropump efficiency and difficulty in reaching the ideal level of output capacity, so as to facilitate mass production, improve stability and reliability, and overcome clogging problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

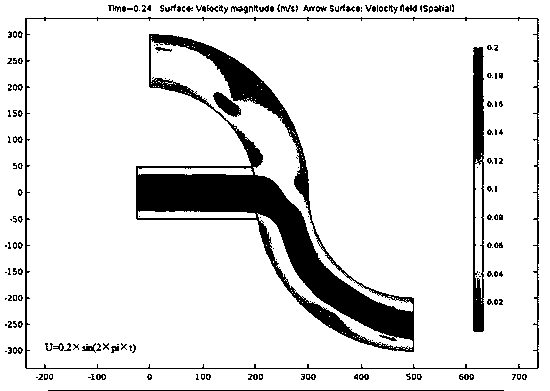

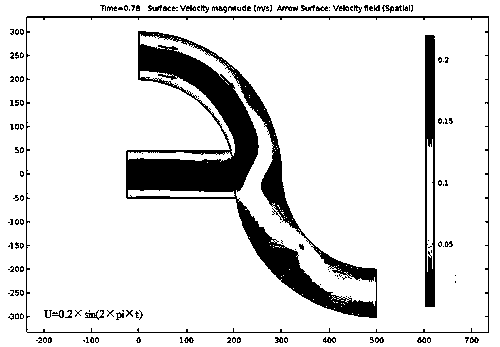

[0020] A valveless reciprocating micropump, using PDMS as the material, through photolithography, development and other process steps to make the SU8 mold; then apply the PDMS material mixed with the curing agent on the mold, and then release the mold after heating and curing Obtain the PDMS negative mold; then apply the PDMS material mixed with the curing agent on the PC sheet, and then heat and cure it to release the mold to obtain a PDMS flat plate; assemble the linear elastic rod according to the requirements, and then bond the PDMS negative mold and the flat plate to obtain a microstructure That is the micropump structure.

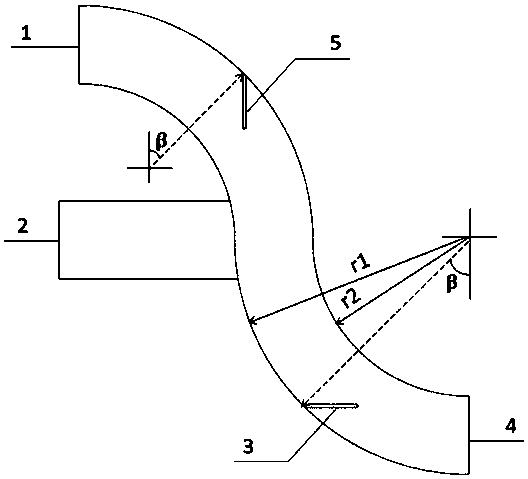

[0021] The micropump includes an inlet pipe, an upper main pipe, a lower main pipe, a vertical linear elastic rod and a horizontal linear elastic rod, wherein the upper main pipe and the lower main pipe are connected together to form an "S"-shaped main pipe that needs to pump fluid, At the same time, the radius r2 of the inner tube of the main pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com