Combination process for preparing liquefied natural gas (LNG) through high-oxygen-content and high-nitrogen-content coalbed methane

A technology of liquefied natural gas and combined process, applied in the field of coalbed methane to liquefied natural gas, can solve the problems of less research on the removal of high oxygen content and low oxygen content of coalbed methane, so as to eliminate hidden dangers of oxygen, improve methane recovery rate and reduce The effect of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

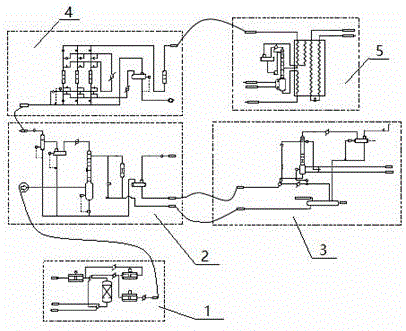

[0034] Embodiment 1: as attached figure 1 As shown, the deoxygenated coalbed gas outlet 113 of the deoxygenation booster unit 1 is connected to the deoxygenation inlet 209 of the deacidification absorption unit 2, and the outlet 211 of the de-poor rich liquid heat exchanger of the deacidification absorption unit 2 is connected to the inlet of the amine liquid storage tank. 212 are respectively connected to the self-flash tank inlet 308 of the deacidification regeneration unit 3 and the outlet of the amine solution pump 309, the deacidification natural gas outlet 210 of the deacidification absorption unit 2 is connected to the deacidification coalbed gas inlet 408 of the dehydration unit 4, and the dehydration unit The dry natural gas outlet 410 of 4 is connected to the dehydrated natural gas inlet 508 of the refrigeration rectification unit 5;

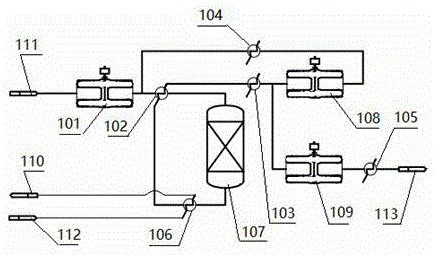

[0035] In the deoxygenation pressurization unit 1, as attached figure 2 As shown, the coalbed methane inlet 111 is divided into two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com