A staggered bed drying device

A technology of drying device and fixed bed, which is applied in the direction of drying, dryer, drying gas arrangement, etc. It can solve the problems of low thermal efficiency, large power consumption, and small production capacity of a single machine, and achieve the effect of high thermal efficiency and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

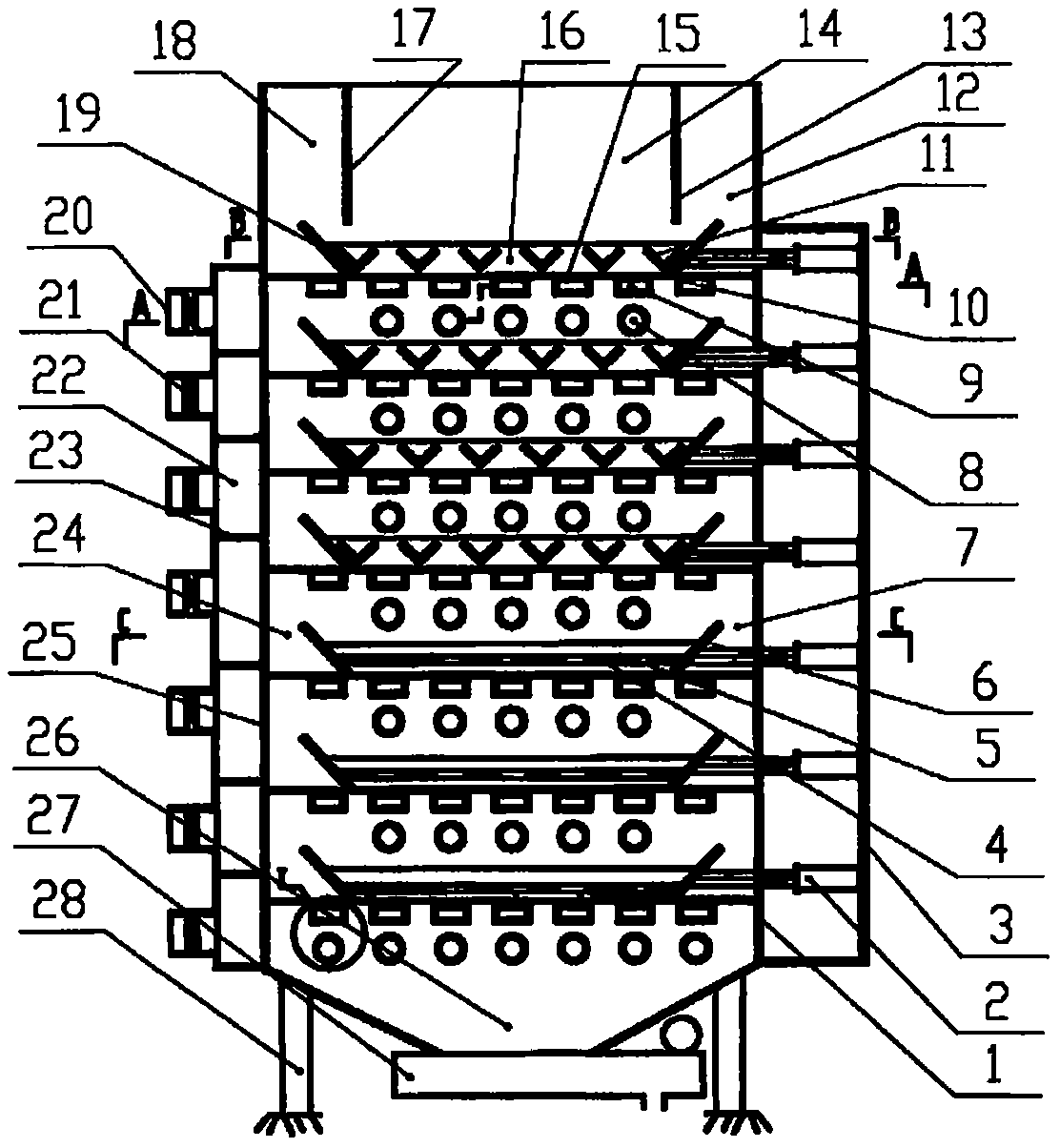

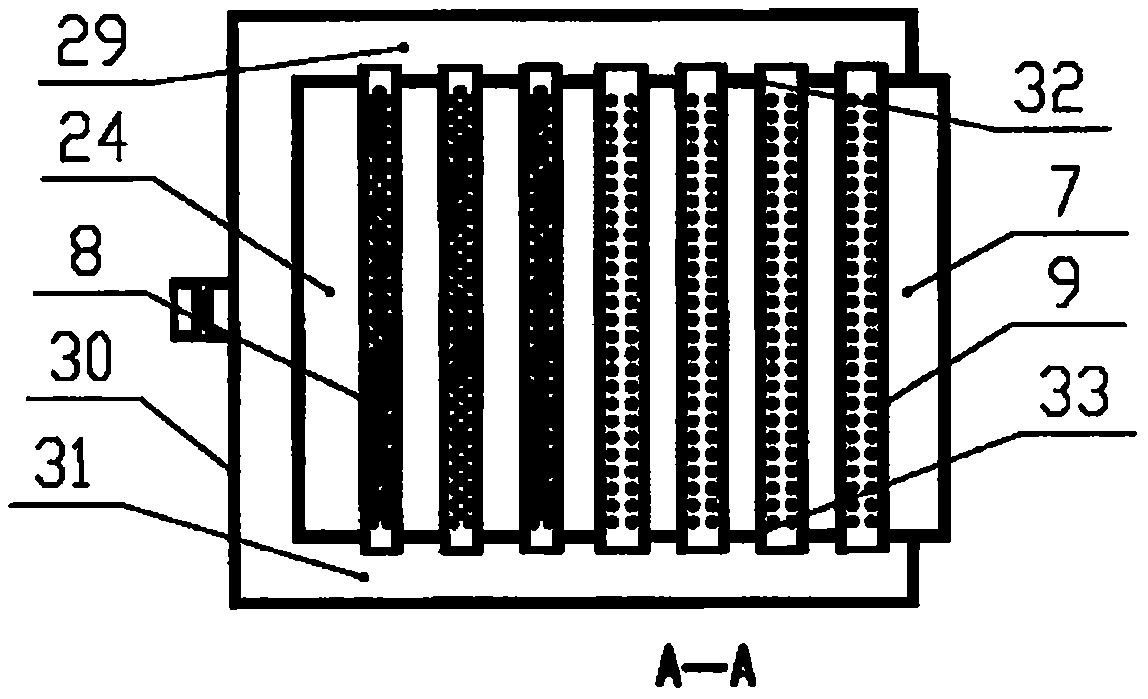

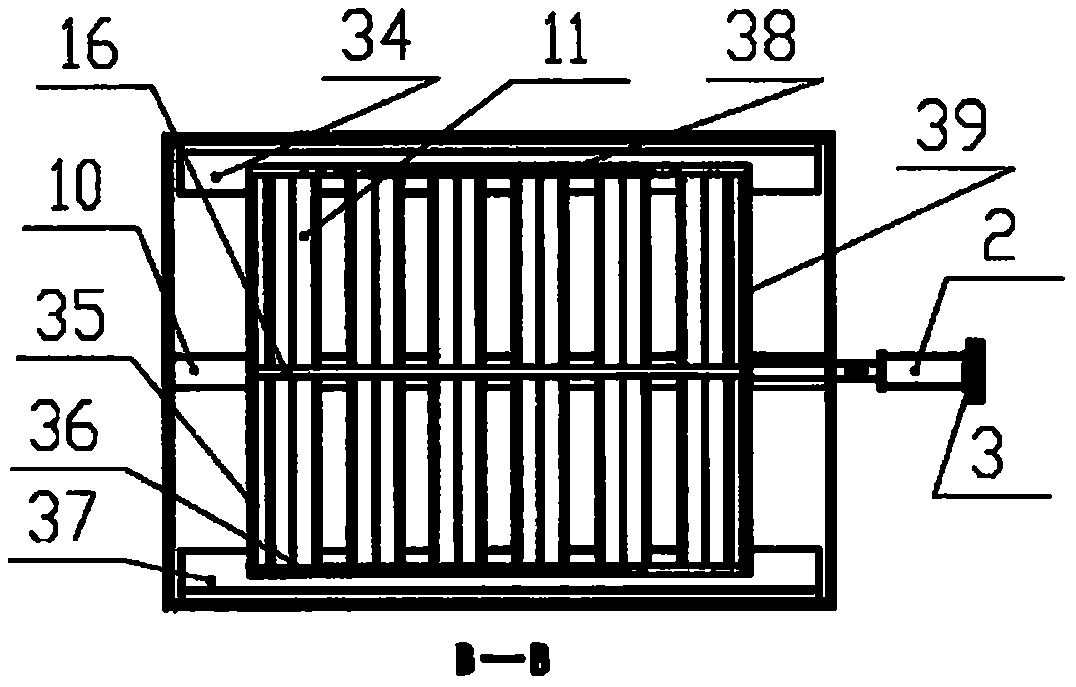

[0025] Such as Figure 1 to Figure 4 A staggered bed drying device shown is composed of a main body front plate 25, a main body rear plate 1, a main body left plate 33, and a main body right plate 32 to form a vertical rectangular box main body supported by legs 28; the upper part of the main body is provided with The silo 14, the front moisture outlet 18, and the rear moisture outlet 12 are surrounded by the silo rear plate 13, the silo front plate 17, the main body right plate 32, and the main body left plate 33; the finished product hopper 26 and the conveyor 27 are arranged at the lower part of the main body; The side of the main body is provided with a multi-layered hot air channel 22 from top to bottom, a left hot air header 31, a right hot air header 29 and a hot air inlet 20; The bed 19 is connected to the oil hydraulic cylinder transmission assembly 2 of the slab movable bed 6 .

[0026] The main body is provided with multi-level layers consisting of angle steel 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com