Ultralow residual reflectance ZnS substrate long wave antireflection film

A residual reflection and anti-reflection technology, applied in optical components, optics, instruments, etc., can solve the problems of immaturity, unable to meet the bandwidth and ultra-low residual reflectivity at the same time, and achieve the effect of avoiding shedding and cracking and high application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

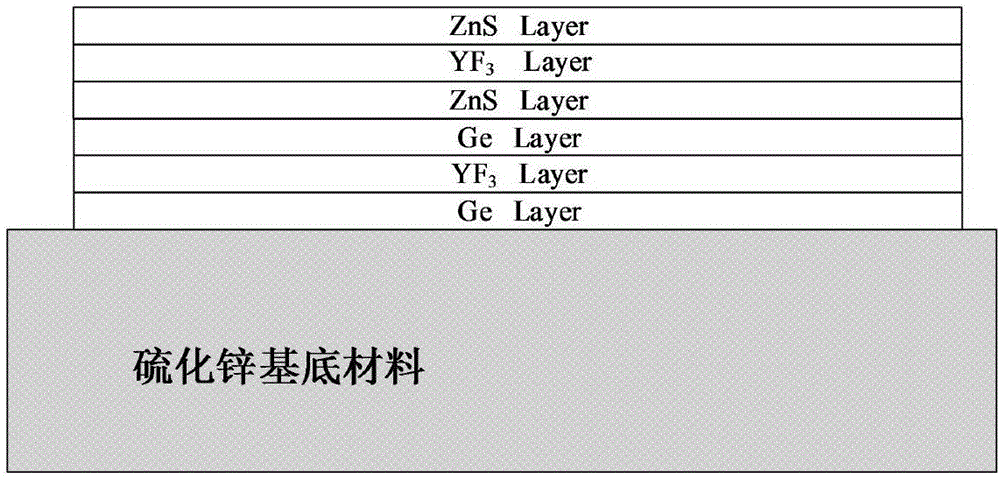

[0033] In order to solve the technical problems in the prior art, the present invention provides an ultra-low residual reflectance ZnS substrate long-wave anti-reflection film, the structure of the anti-reflection film is:

[0034] Sub / x 1 x 2 Lx 3 x 4 M x 5 x 6 M / Air

[0035] Among them, the substrate Sub is ZnS, H, M and L represent high refractive index, medium refractive index and low refractive index materials respectively, x 1 ~x 6 Represent the optical thickness coefficient of each layer of film, and the unit optical thickness is λ 0 / 4.

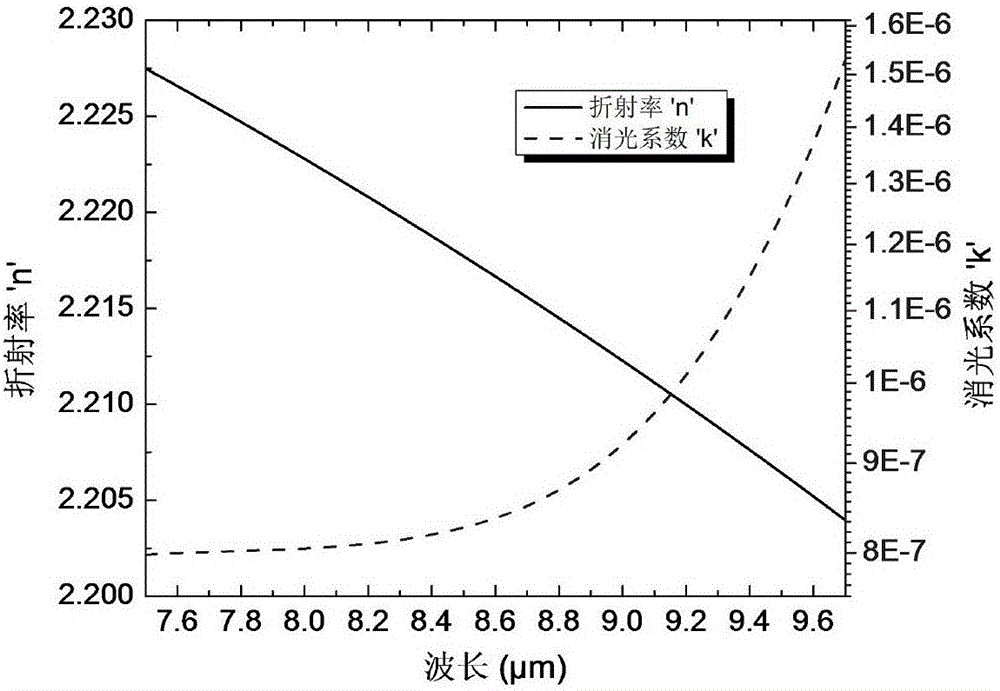

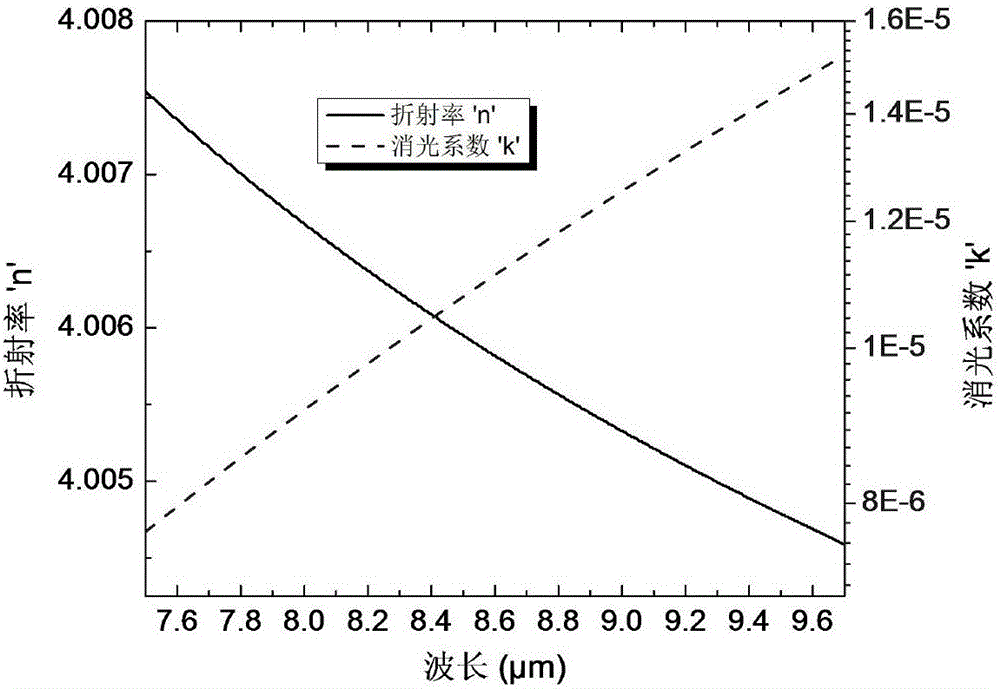

[0036] Further, the high, medium and low refractive index materials are germanium, zinc sulfide and yttrium fluoride respectively.

[0037] The optical thickness coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com