P type layer open pipe Al diffusion silicon element and preparation method thereof

A technology for diffusing silicon and components, which is applied in the field of P-type layer open-tube Al diffusion silicon components and their preparation, can solve the problems of low surface concentration, poor diffusion consistency, poor intra-chip uniformity, etc., and achieves low equipment requirements and simple preparation method. , The effect of strong industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a P-type layer open tube Al diffused silicon element, comprising the following steps:

[0029] Step 1, coating an Al film on the Si surface;

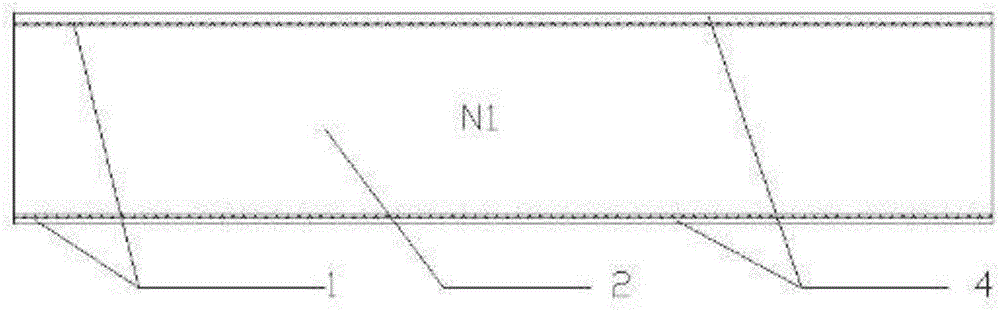

[0030] Step 2, Al-Si alloy layer 1 is formed by alloying, such as figure 1 As shown, that is, the Si surface includes an Al-Si alloy layer 1 and an Al film layer 4;

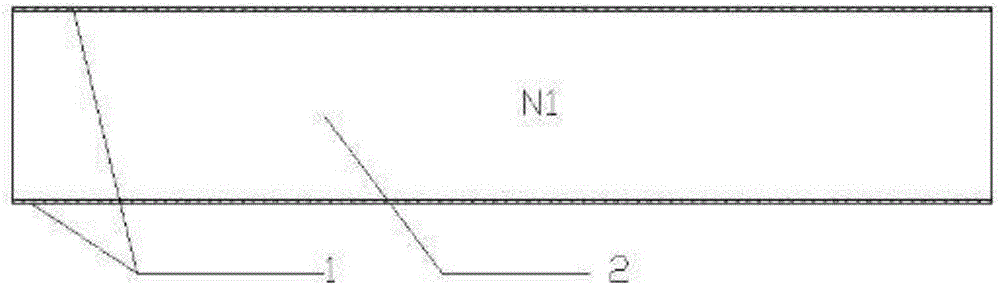

[0031] Step 3, remove the Al film layer 4, such as figure 2 As shown, the Al-Si alloy layer 1 is obtained as the Al impurity source;

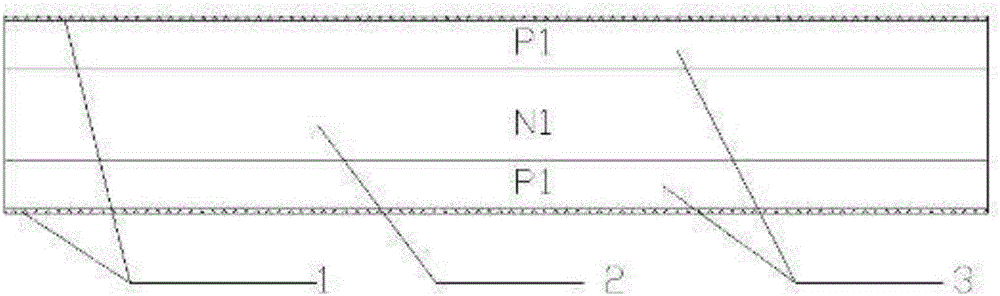

[0032] Step 4: advance the junction depth of the Al-Si alloy layer 1 and the Si layer at a certain temperature and a certain atmosphere for a certain period of time, so that Al diffuses to Si, that is, the formation of image 3 the structure shown;

[0033] Step five, post-processing, that is, to obtain the product.

[0034] Specifically, such as figure 1 As shown, the N-type high-resistance silicon chip used in the high-voltage rectifying element and the high-voltage thyristor constitutes the N-type hig...

Embodiment 2

[0038] A method for preparing a P-type layer open tube Al diffused silicon element, comprising the following steps:

[0039] Step 1, coating an Al film on the Si surface;

[0040] Step 2, forming an Al-Si alloy layer by alloying, such as figure 1 As shown, that is, the Si surface includes an Al-Si alloy layer 1 and an Al film layer 4;

[0041] Step 3, remove the Al film layer 4, such as figure 2 As shown, the Al-Si alloy layer 1 is obtained as the Al impurity source;

[0042] Step 4: advance the junction depth of the Al-Si alloy layer 1 and the Si layer at a certain temperature and a certain atmosphere for a certain period of time, so that Al diffuses to Si, that is, the formation of image 3 the structure shown;

[0043] Step five, post-processing, that is, to obtain the product.

[0044] Specifically, such as figure 1 As shown, the N-type high-resistance silicon wafer used for the high-voltage rectifier element and the high-voltage thyristor constitutes the N-type hig...

Embodiment 3

[0048] A method for preparing a P-type layer open tube Al diffused silicon element, comprising the following steps:

[0049] Step 1, coating an Al film on the Si surface;

[0050]Step 2, forming an Al-Si alloy layer by alloying, such as figure 1 As shown, that is, the Si surface includes an Al-Si alloy layer 1 and an Al film layer 4;

[0051] Step 3, remove the Al film layer 4, such as figure 2 As shown, the Al-Si alloy layer 1 is obtained as the Al impurity source;

[0052] Step 4: advance the junction depth of the Al-Si alloy layer 1 and the Si layer at a certain temperature and a certain atmosphere for a certain period of time, so that Al diffuses to Si, that is, the formation of image 3 the structure shown;

[0053] Step five, post-processing, that is, to obtain the product.

[0054] Specifically, such as figure 1 As shown, the N-type high-resistance silicon wafer used for the high-voltage rectifier element and the high-voltage thyristor constitutes the N-type high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com