Homogenate coating method for negative lithium titanate and method for preparing lithium ion battery with negative lithium titanate

A negative electrode lithium titanate and lithium ion battery technology, which is applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve the problems of environmental humidity sensitivity, affecting the homogenization and coating effect of lithium titanate materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] 1. A homogenate coating method of negative electrode lithium titanate, the method comprising the steps of:

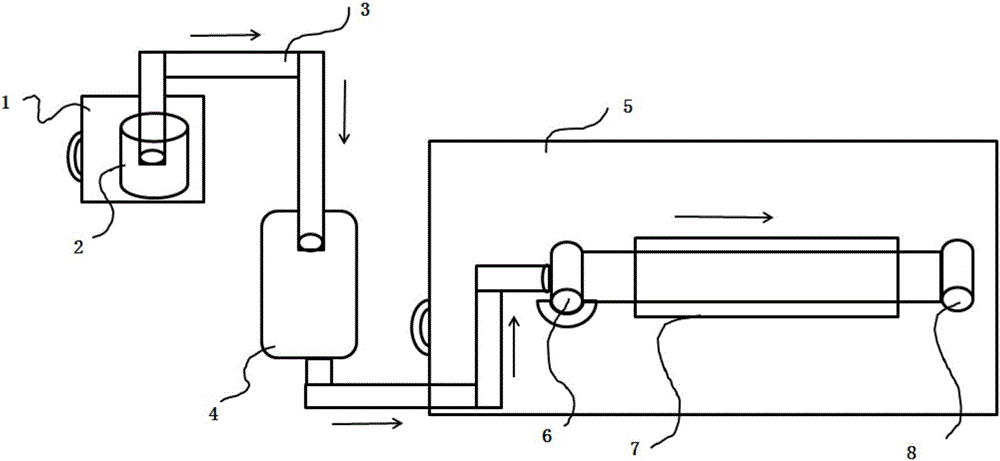

[0044] a. Connect the purchased material storage box 1, homogenization tank 4 and coating chamber 5 through the delivery pipeline 3 into an integrated homogenization and coating equipment, and connect the air replacement device to the material storage box 1 and the homogenization unit through the gas pipeline. On the slurry tank 4; a dehumidifier is provided in the coating chamber 5; the material storage box 1 is a glove-tight box;

[0045] b. Turn on the air replacement button and pump dry N 2 , control the humidity in the material storage tank 1 and the homogenization tank 4 within the range of 10% RH, and then close the valves of each connection interface;

[0046] c. Transport and transfer the material packaging barrels 2 respectively containing the homogenizing solvent N-methylpyrrolidone (NMP), the negative electrode active material pure lithium titanate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com