Multi-nozzle spray dryer, method for scale-up of spray dried inhalation powders, multi-nozzle apparatus and use of multiple nozzles in a spray dryer

一种喷雾干燥器、多喷嘴的技术,应用在喷雾蒸发、块状输送、液体分成珠滴颗粒化等方向,能够解决没有公开关键性能标准等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0048] This example considers a scaled-down version of the invention (eg Figure 6 shown) to demonstrate a proof-of-concept.

[0049] A feed mixture was prepared by dissolving 1.2 g of lysine and 4.8 g of trehalose in 234 g of water (total solids concentration approximately 2.5% w / w). Such excipient systems are known to produce amorphous powders in which the particle size is sensitive to changes in nebulization conditions. Therefore, this excipient system is ideal for the current proof-of-concept.

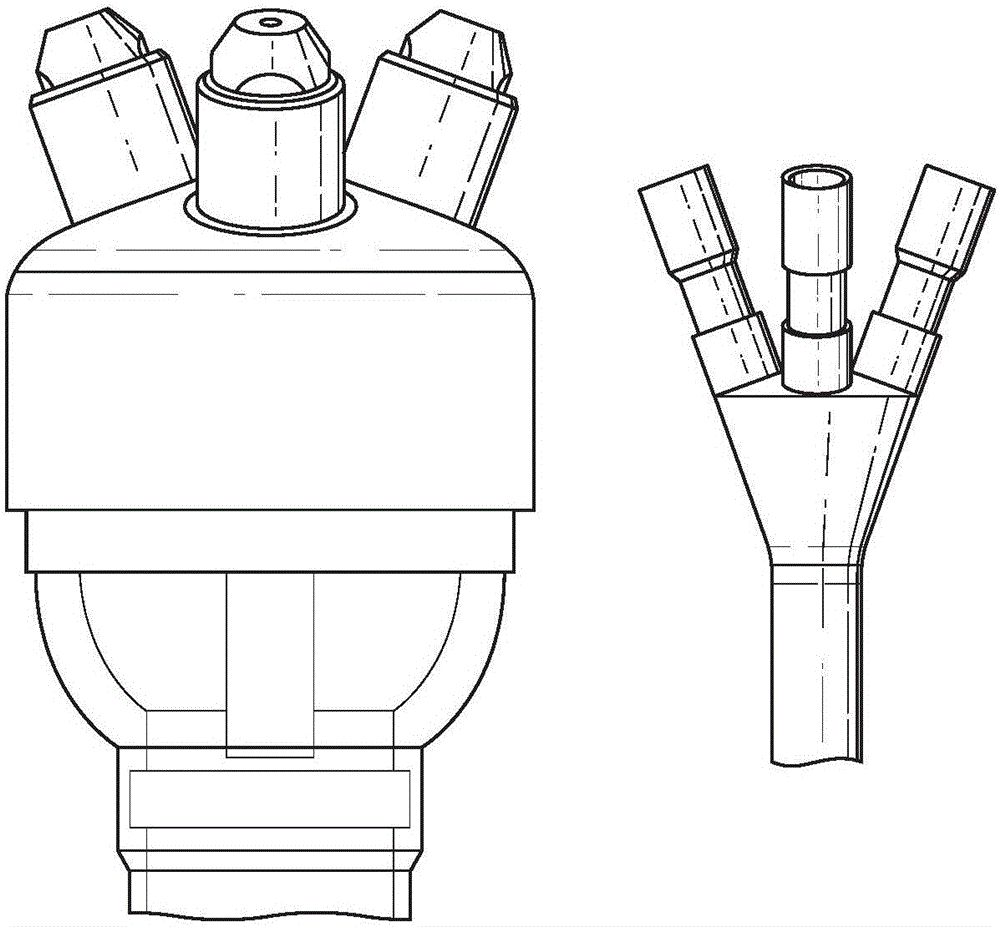

[0050] A laboratory scale spray dryer (BUCHI model B-290 Advanced) was used to process the above feed solution. In trial #1, the BUCHI unit was equipped with a single two-fluid nozzle with a nozzle cap and diameter of 1.4 and 0.7 mm, respectively. In trial #2, the BUCHI unit was equipped with a pair of two-fluid nozzles ( Figure 6 ), each with a nozzle cap and diameter of 1.4 and 0.7 mm (ie, the same as the nozzle for Test #1).

[0051] During the first test, the flow rate of...

example 2

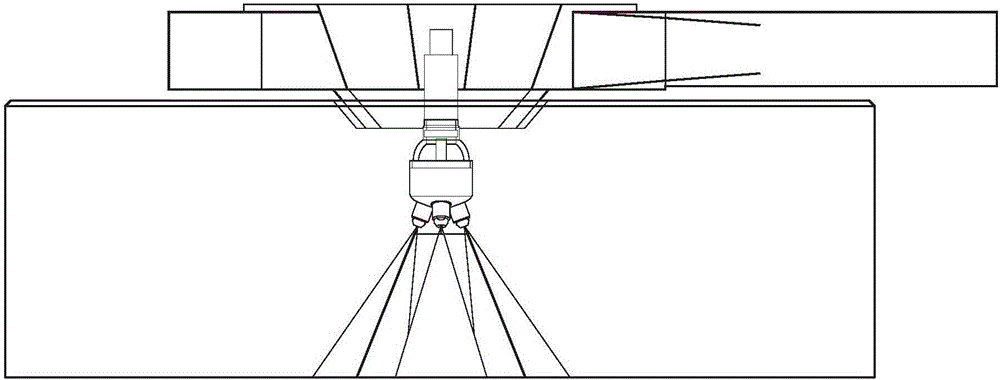

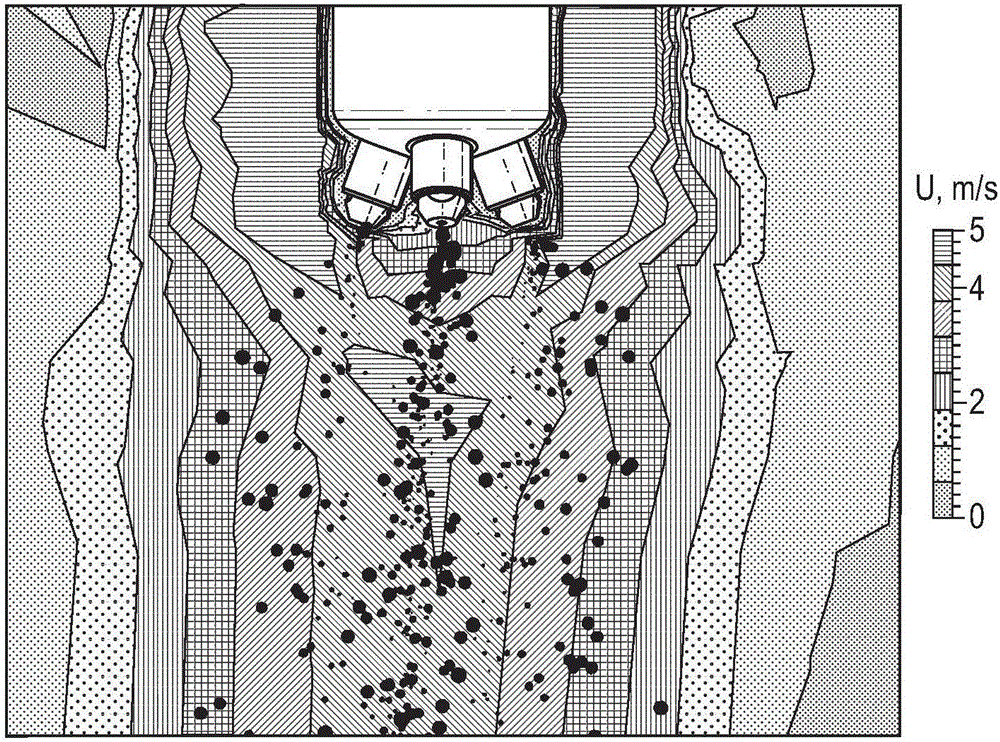

[0059] This example considers the inventive multi-nozzle atomizer utilized in the SD1 unit ( figure 1 shown in ) demonstrates a proof-of-concept.

[0060] A feed mixture was prepared by dissolving 1.225 kg leucine and 4.9 kg trehalose in 33.8 kg ethanol and 135.1 kg water (total solids concentration approximately 3.5% w / w).

[0061] An SD1 operating at a nominal drying gas flow rate of about 110 kg / h was used to treat the above feed solution. In trial #1, the SD1 unit was equipped with a multi-nozzle atomizer operating with 2NIRO ETFN (hole = 0.5 mm) and a special housing for uniform liquid and gas distribution. In trial #2, the SD1 unit was equipped with a multi-nozzle atomizer operating with 1 NIRO ETFN (hole = 0.5 mm).

[0062] During the first test, the flow rate of the solution supplied to the two nozzles of the multi-nozzle atomizer was about 2 kg / h, and the flow rate of the atomizing gas supplied to the device was about 20 kg / h.

[0063] During the second test, the f...

example 3

[0069] This example considers the multi-nozzle atomizer of the present invention utilized in a commercial scale spray dryer unit ( figure 1 shown) demonstrates a proof-of-concept.

[0070] A feed mixture was prepared by dissolving 1.225 kg leucine and 4.9 kg trehalose in 33.8 kg ethanol and 135.1 kg water (total solids concentration approximately 3.5% w / w).

[0071] The above feed solution was treated using an SD2 operating at a nominal dry gas flow rate of about 360 kg / h. The SD2 unit is equipped with a multi-nozzle atomizer special housing operated with 4NIRO ETFN (hole = 0.5mm) for uniform liquid and gas distribution.

[0072] During the test, the flow rate of the solution supplied to the multi-nozzle atomizer was about 8 kg / h, and the flow rate of the atomizing gas supplied to the device was about 20 g / h.

[0073]

[0074] as from Figure 11 (Multi-nozzle atomizer operated with 4 nozzles) It can be seen that the particle size distribution and morphology are identical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com