Porous carbon films

一种多孔碳、基膜的技术,应用在化学领域,能够解决低机械强度、低电导率、繁琐等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0064] 1 Introduction

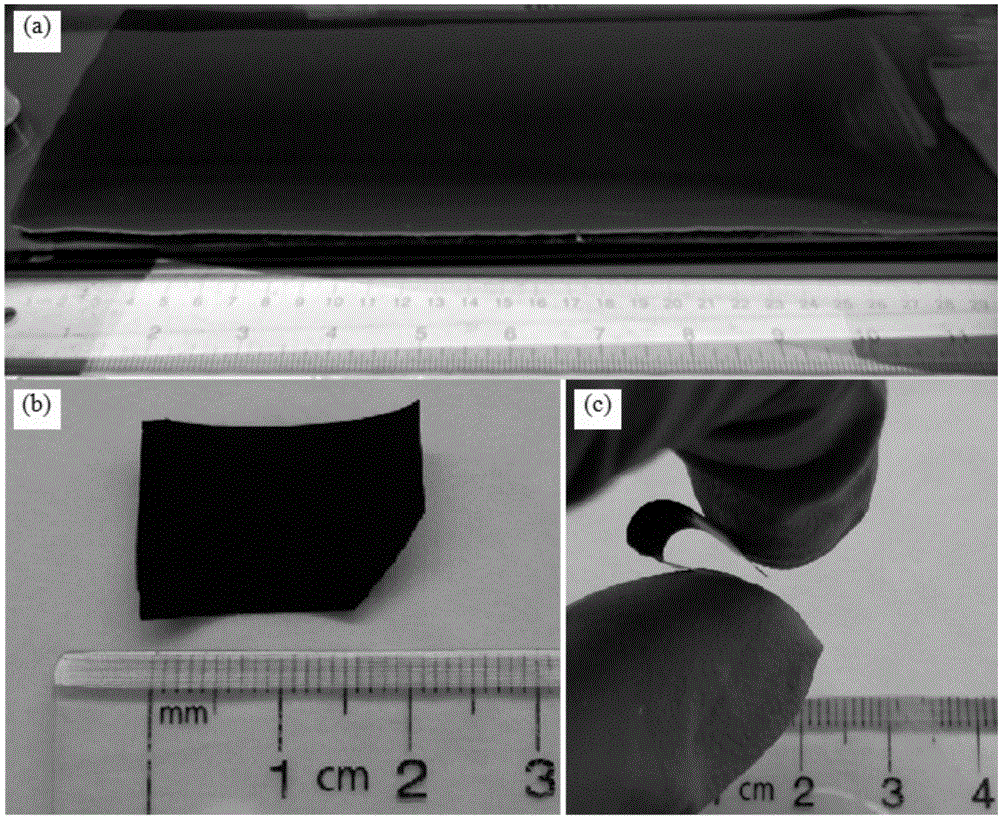

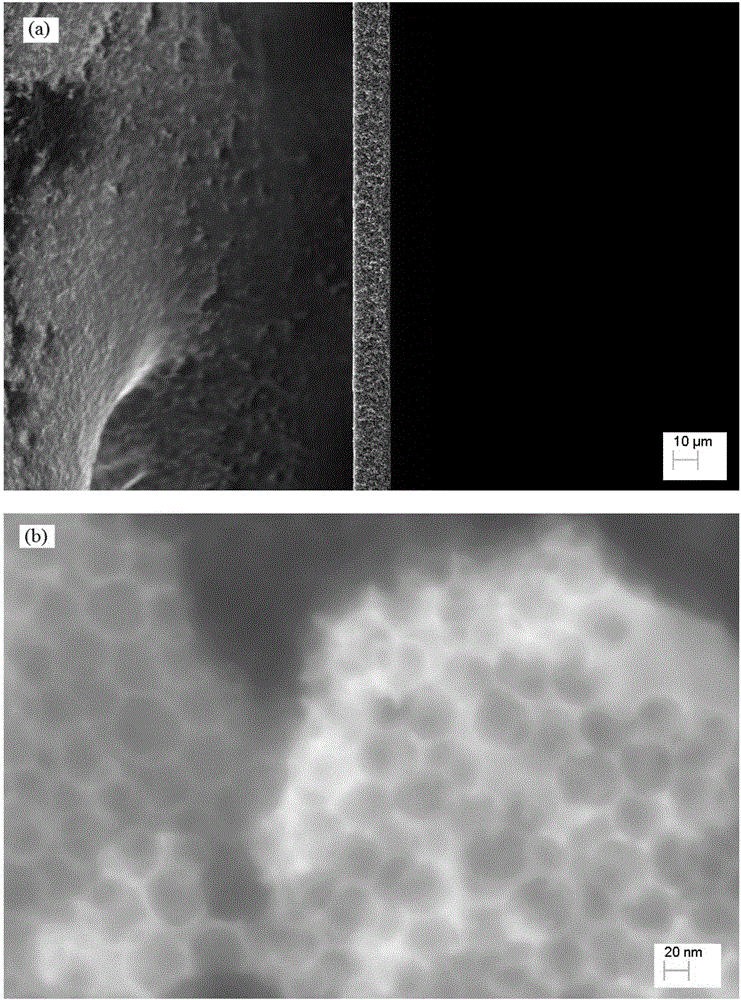

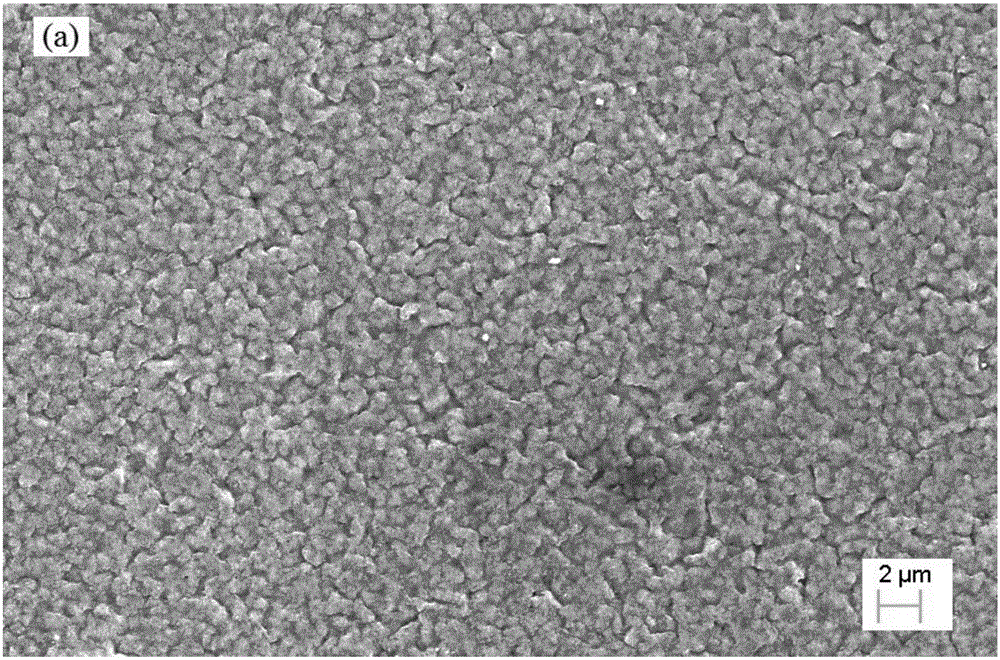

[0065] In the work described in this example, a scalable production method was developed based on colloidal imprinted carbon (CIC) for the preparation of self-supporting nanoporous carbon films (NCF), including the following steps: 1) will contain carbon precursors including An aqueous precursor mixture of body, surfactant, silica-based structural template, binder, plasticizer, and additives is coated on a substrate, 2) the mixture is dried to form a film, and 3) the film is thermally treated (carbonized) , then 4) remove the silica template. Casting is the preferred method for preparing these films because it is suitable for fabrication on a large scale [7, 16, 17]. The thickness of the film can be controlled (for example, from 100 nm to 1 mm) by changing the concentration of the aqueous precursor mixture or adjusting the gap between the doctor blade and the substrate during casting. In this example, the pore size of the membrane was controlled by us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com