Wall covering and method of producing the same

A technology for coverings and walls, applied in the direction of acidic copolymer adhesives, adhesive types, film/sheet adhesives, etc., can solve the problems of lack of moisture barrier, difficult to remove wall coverings, etc., to achieve The effect of low sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0098] To achieve a repositionable adhesive coating, a polyacrylic acid precursor (a water-soluble monomer, preferably an α,β-ethylenically unsaturated carboxylic acid monomer commercially known as PD8081H, composed of rich The aqueous product supplied by HB Fuller) was mixed with a cross-linking agent, ammonium zirconium carbonate (AZC).

[0099] The amount of cross-linking agent added is not enough to achieve complete compounding of polyacrylic acid monomers.

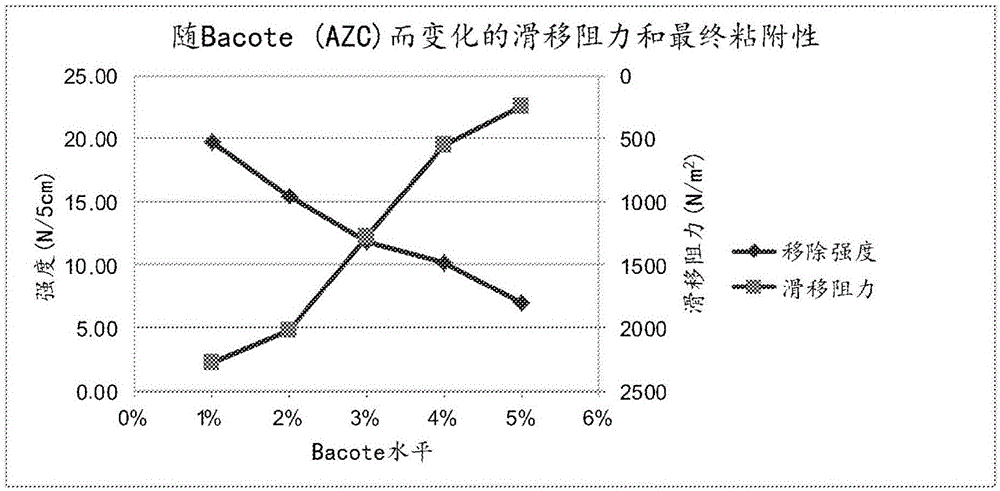

[0100] figure 1 Slip resistance and final adhesion as a function of crosslinker concentration are shown. The results were obtained under the following conditions:

[0101] - Water application: 130 grams per square meter on the substrate

[0102] -3 minute wetting time before application to primed plasterboard

[0103] - Analysis of slip resistance after 10 minutes

[0104] - Analysis of final adhesion after 28 hours.

[0105] As evident from the figure, by limiting the amount of AZC in the aqueous polyacrylic a...

example 2

[0114] Peelable, repositionable wall covering rolls are prepared as follows:

[0115] 130 grams of nonwoven wall covering were used as the base substrate. On the backside of the base substrate, a precoat is applied using a precoat formulation. The preparation has the following composition:

[0116] 30% Rhoplex E 3482 (Dow), acrylic latex

[0117] 70% Barrisurf HX (Imerys), a very high profile clay

[0118] Coatings were prepared at 64% solids. The coat weight was 10 grams. Drying of the coated coils was carried out at elevated temperature (130° C.).

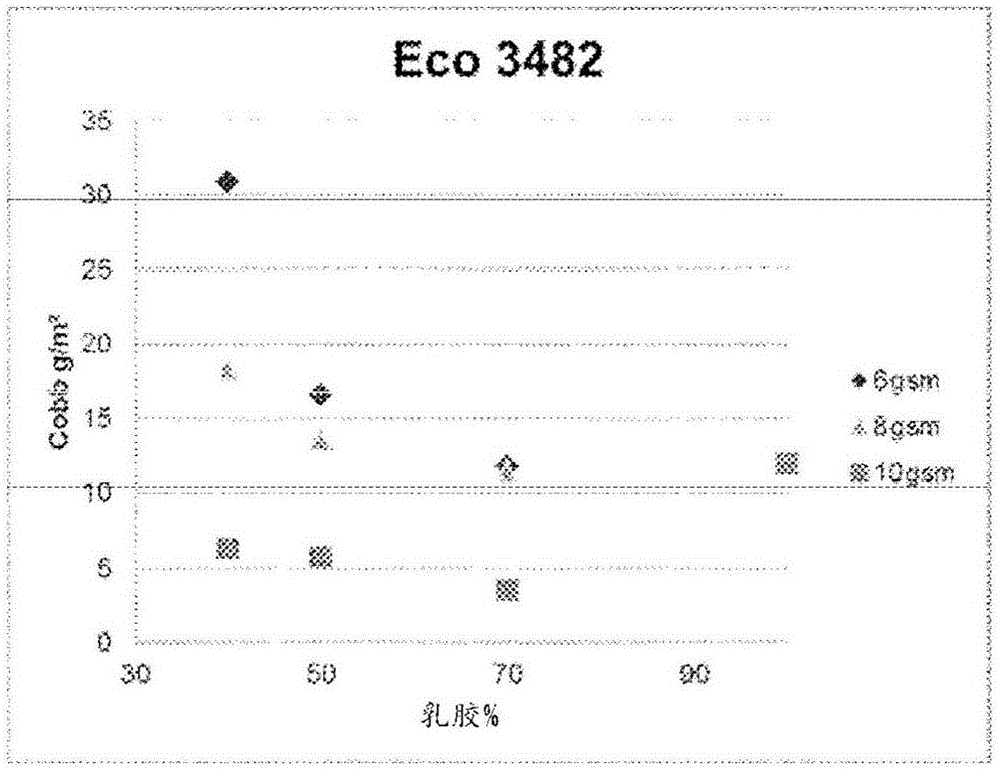

[0119] The water permeability / absorption of the base substrate was measured by Cobb (1 minute). result in figure 2 given in.

[0120] As is evident from the figure, the precoat consisting of latex Rhoplex E 3482 and clay Barrisurf HX formed an effective barrier coating.

[0121] On the precoated coils thus obtained, a top coat was applied.

[0122] The top coat is an aqueous dispersion with the following composition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com