Modified polyvinylidene fluoride ultrafiltration membrane and preparation method thereof

A polyvinylidene fluoride and ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve problems such as limited water resources, and achieve the effect of long durable life and high superabsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

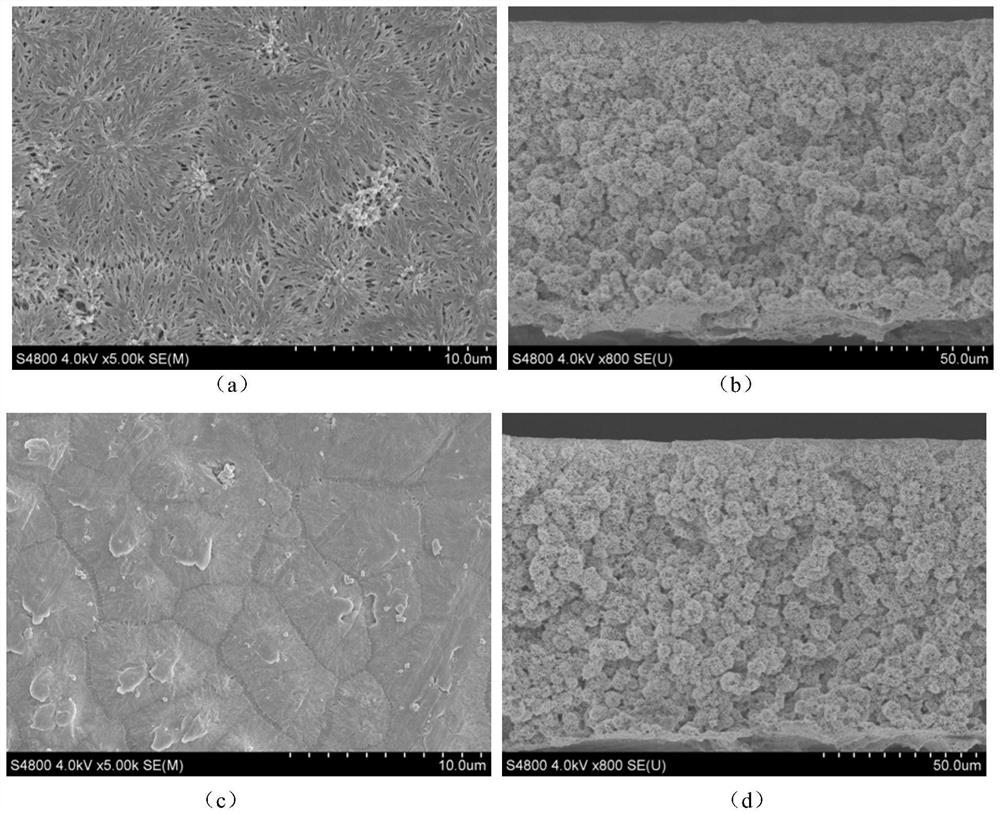

[0032] An embodiment of the modified polyvinylidene fluoride ultrafiltration membrane of the present invention, the preparation method of the modified polyvinylidene fluoride ultrafiltration membrane described in this embodiment comprises the following steps:

[0033] One, prepare polyvinylidene fluoride ultrafiltration membrane, comprise the following steps:

[0034] (a) PVDF was dissolved in triethyl phosphate at 70° C., and stirred under nitrogen at a mechanical stirring speed of 400 rpm for 10 h to obtain a homogeneous solution;

[0035] (b) Carry out vacuum degassing to the homogeneous solution prepared in step (a), remove the microbubbles therein, obtain casting solution, scrape the casting solution onto the non-woven fabric, and quickly soak it in the coagulation bath V 磷酸三乙酯 :V 水 =5:5, soak for 20s to get primary PVDF ultrafiltration membrane;

[0036] (c) solidifying the primary PVDF ultrafiltration membrane obtained in step (b) in deionized water, and drying to obt...

Embodiment 2

[0042] An embodiment of the modified polyvinylidene fluoride ultrafiltration membrane of the present invention, the preparation method of the modified polyvinylidene fluoride ultrafiltration membrane described in this embodiment comprises the following steps:

[0043] One, prepare polyvinylidene fluoride ultrafiltration membrane, comprise the following steps:

[0044] (a) PVDF was dissolved in triethyl phosphate at 80° C., and stirred under nitrogen at a mechanical stirring speed of 500 rpm for 12 hours to obtain a homogeneous solution;

[0045] (b) Carry out vacuum degassing to the homogeneous solution prepared in step (a), remove the microbubbles therein, obtain casting solution, scrape the casting solution onto the non-woven fabric, and quickly soak it in the coagulation bath V 磷酸三乙酯 :V 水 =5:5, soak for 30s to get primary PVDF ultrafiltration membrane;

[0046] (c) solidifying the primary PVDF ultrafiltration membrane obtained in step (b) in deionized water, and drying to...

Embodiment 3

[0052] An embodiment of the modified polyvinylidene fluoride ultrafiltration membrane of the present invention, the preparation method of the modified polyvinylidene fluoride ultrafiltration membrane described in this embodiment comprises the following steps:

[0053] One, prepare polyvinylidene fluoride ultrafiltration membrane, comprise the following steps:

[0054] (a) PVDF was dissolved in triethyl phosphate at 90° C., and stirred under nitrogen at a mechanical stirring speed of 600 rpm for 14 hours to obtain a homogeneous solution;

[0055] (b) Carry out vacuum degassing to the homogeneous solution prepared in step (a), remove the microbubbles therein, obtain casting solution, scrape the casting solution onto the non-woven fabric, and quickly soak it in the coagulation bath V 磷酸三乙酯 :V 水 =5:5, soak for 40s to get primary PVDF ultrafiltration membrane;

[0056] (c) solidifying the primary PVDF ultrafiltration membrane obtained in step (b) in deionized water, and drying to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com