Bin applicable to solid and semisolid medium materials

A semi-solid, silo technology, applied in the field of automation equipment, can solve the problems of unguaranteed continuity and rapidity of unloading, and achieve the effect of easy unloading, reasonable overall structure design, and clean and thorough discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

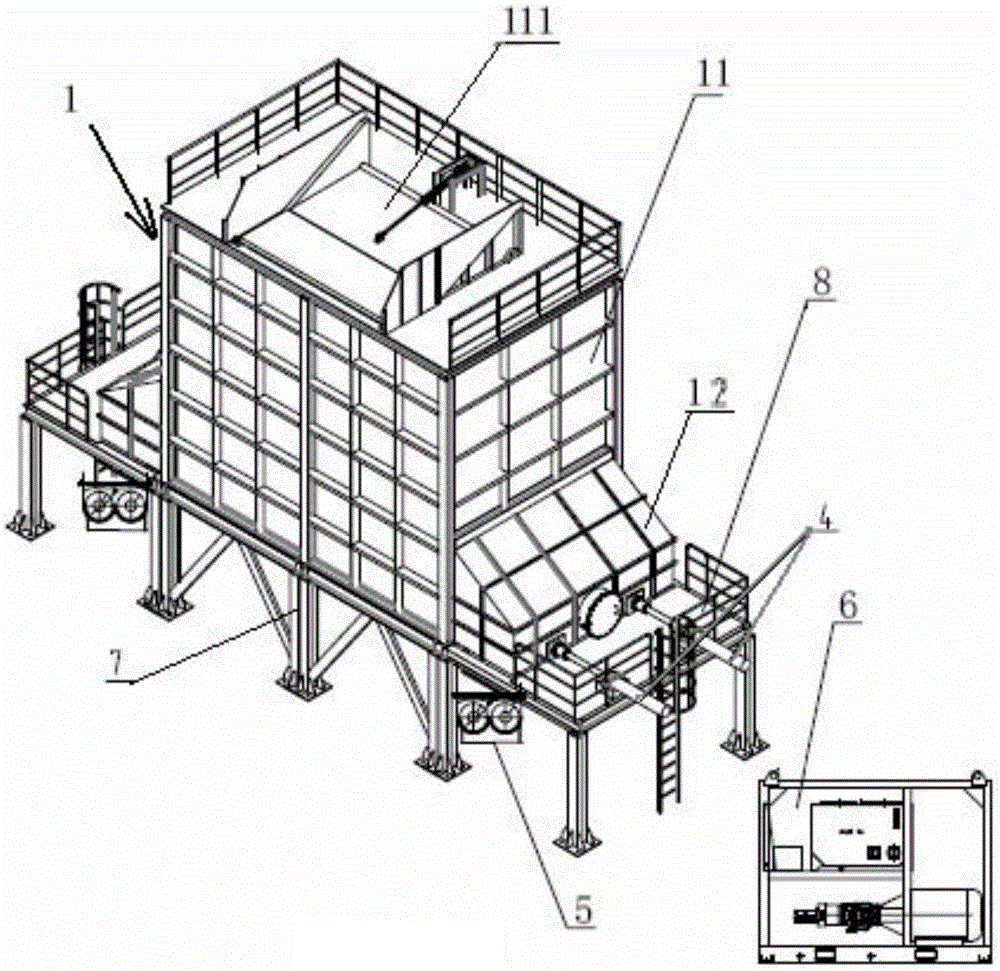

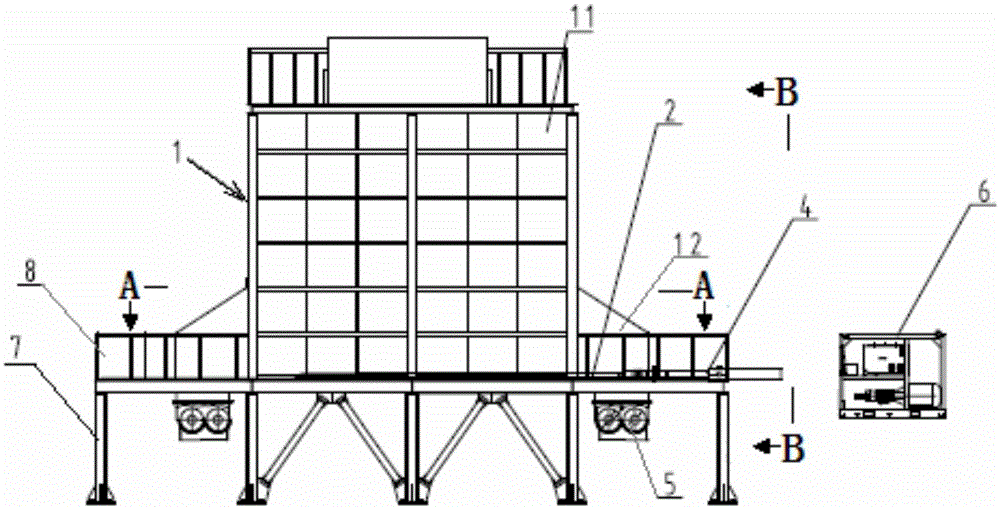

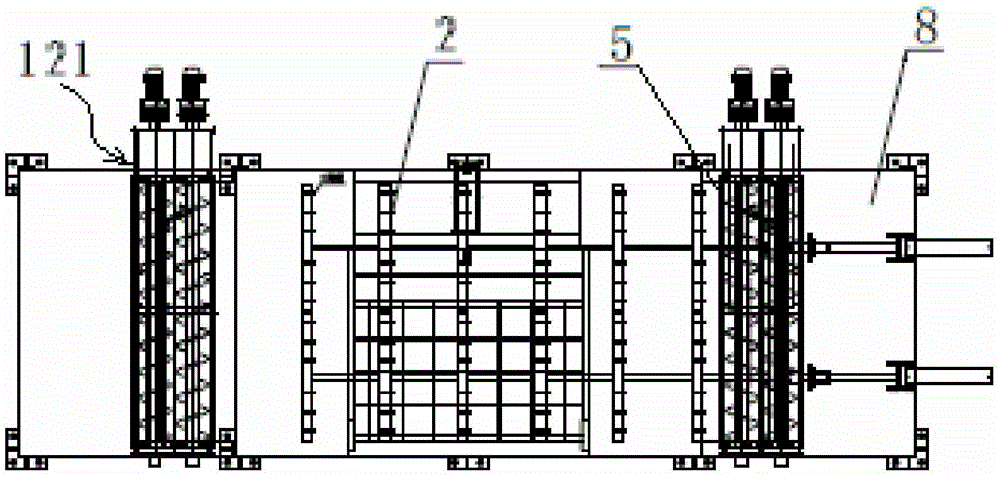

[0042] see Figure 1 to Figure 4 As shown, the silo of the present invention is mainly composed of a silo main structure unit 1, a heavy-duty carriage unit device, a hydraulic drive unit 4 (hydraulic cylinder), a discharge unit device 5 (comprising an auxiliary discharge device and a main discharge device), Hydraulic power unit 6 (hydraulic station), platform and stair unit 8 and electric control unit etc. constitute.

[0043] The silo of the present invention can be arranged underground, or can be constructed according to the geographical features and needs of the project site. Figure 1 to Figure 4 A preferred embodiment of the invention is shown. The main structural unit 1 of the silo comprises a main silo 11 and split bins 12 on both sides (a split bin can also be set on one side), and the feed inlet is arranged on the top of the main bin, and the main bin Placed on a structural frame to leave a lower space for the construction of the split bin; the main bin 11 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com