Well cementation rubber plug used for seabed oil well

A technology for subsea oil wells and cementing plugs, which can be used in wellbore/well components, earthwork drilling, sealing/isolation, etc., and can solve problems affecting cementing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

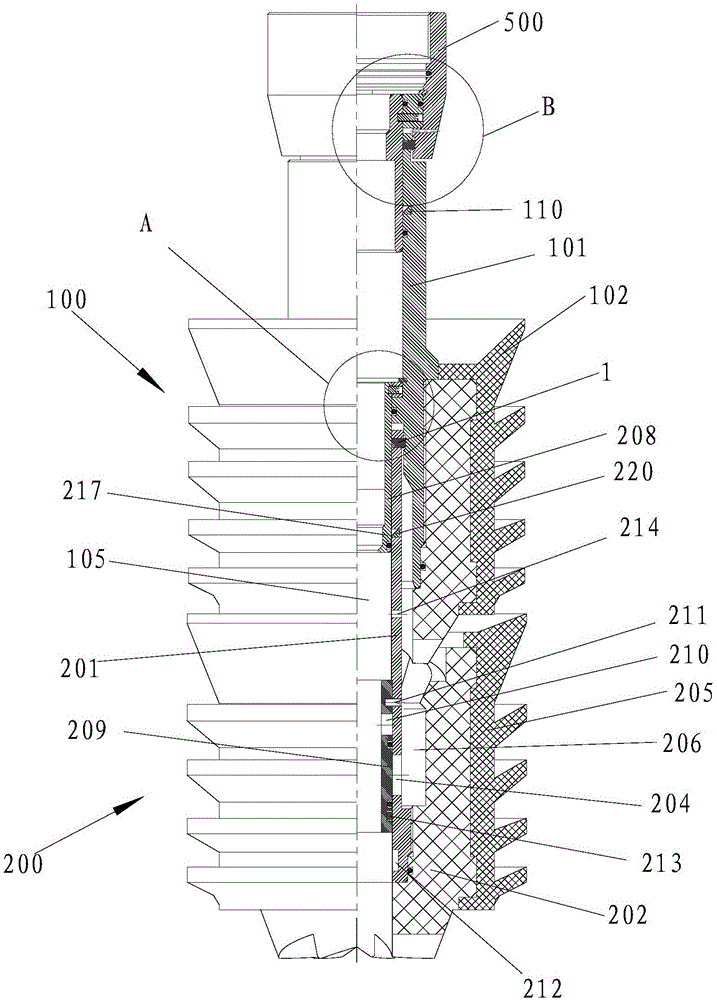

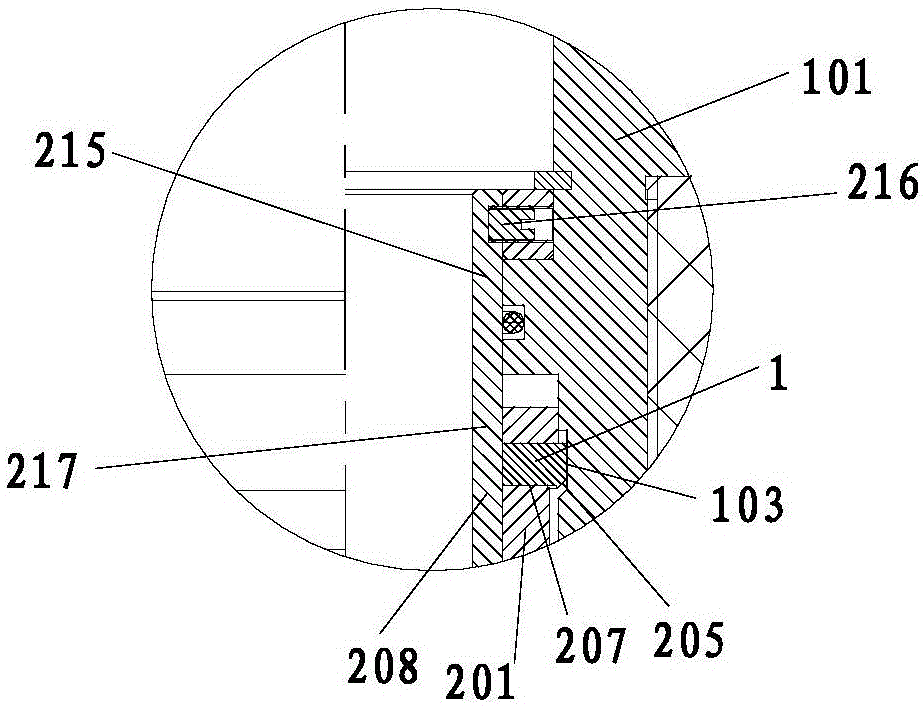

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] Generally, for a subsea oil well, the wellhead of the subsea oil well is arranged on the seabed surface and is connected to a drilling platform arranged on the sea surface through a riser extending to the sea surface. A casing is arranged in the subsea oil well, and a hollow drill pipe (not shown) communicated with the casing (not shown) is arranged in the riser. Typically, the diameter of the riser (not shown) is larger than the diameter of the open hole so that the annulus between the casing and the open hole communicates with the space between the riser and the drill pipe. These are well known to those skilled in the art and will not be repeated here.

[0026] figure 1 A top plug 100 and a bottom plug 200 connected in series of a cementing plug according to the present invention are shown. When using this cementing plug to cement a subsea oil well, it needs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com