Wall column template verticality detection ruler and manufacturing method thereof

A production method and a technology for detecting rulers, which are applied in the field of measuring rulers, can solve problems such as the inconvenience of verticality detection of wall column formwork, the influence of formwork frame structure construction quality and overall perception, and the inspection of verticality of wall column formwork by a ruler, so as to ensure the concrete The effect of molding appearance quality, reducing engineering cost, and controlling verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

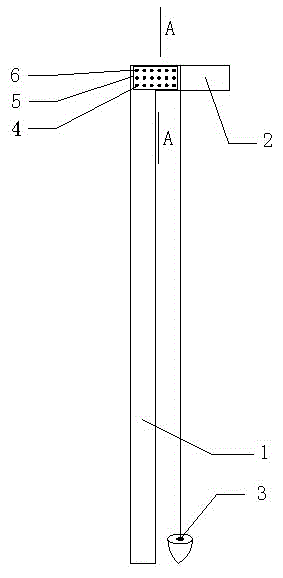

[0031] The verticality detection ruler of the wall stud formwork of the present invention has an inverted L-shaped profile and includes a handle, a ruler and a wire hammer.

[0032] figure 1 It is a structural schematic diagram of the verticality detection ruler of the wall stud formwork according to the embodiment of the present invention, figure 2 for figure 1 Sectional view of A-A in Fig. As shown in the figure, the handle 1 is made of an aluminum alloy square tube with a length of 2m, and the specification of the aluminum alloy square tube is 100*50*2.5mm.

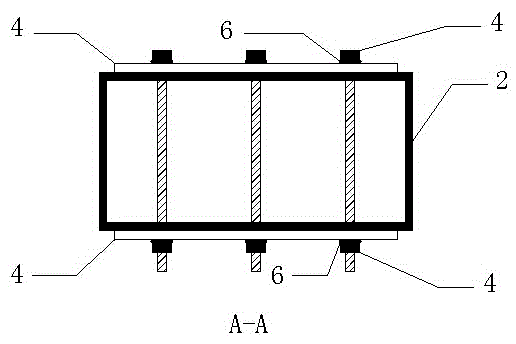

[0033] The ruler 2 is made of an aluminum alloy square tube with a length of 0.3m, and the specification of the aluminum alloy square tube is 100*50*2.5mm. One end of the ruler and one end of the handle are flatly connected with each other through the connecting part, so that the handle and the ruler are vertical; the connecting part is clamped by the backing plates 5 arranged on the two outer sides of the handle a...

Embodiment 2

[0036] The preparation method of verticality detection ruler of wall column formwork of the present invention comprises the following steps:

[0037] a. Choose 100*50*2.5mm aluminum alloy square tube as the handle 1, and the cut length is 2m;

[0038] b. Choose 100*50*2.5mm aluminum alloy square tube with ruler 2, and the interception length is 0.3m;

[0039] c. Use two 180*90*2.5mm aluminum alloy plates to clamp the two sides of the connecting end of the handle 1 and the ruler 2, and then drill the connecting holes together. The length of the connection is 180mm, the width is 100mm, and there are upper, middle and lower holes Three rows of connection holes, each row of six connection holes, and hexagonal bolts are used for connection and fixation; the model specification of the hexagonal bolts is M10*60mm. When the hexagonal bolts are connected and fixed, a copper washer 6 is used between the backing plate 5 and the nut of the hexagonal bolts.

[0040] d. A drooping wire ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com