Efficient denitration system of W-flame boiler

A denitrification and boiler technology, applied in the field of high-efficiency denitrification system of W flame boiler, can solve the problems of low reducing agent concentration in the center of the furnace, high local concentration in the center of the furnace, and reduced denitrification efficiency, achieving high automation, reduced injection, and denitrification efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A high-efficiency denitrification system for W flame boilers, including reducing agent storage and delivery units, SNCR deployment metering and mixing distribution units, multi-region n-layer m combined injection units, SCR removal units, TFC state detection units, data mining and fully automatic control unit.

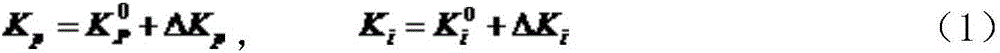

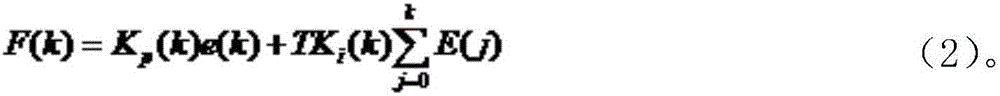

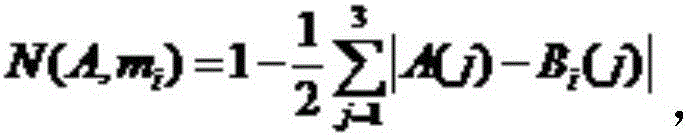

[0041] The specific process is that the data mining and automatic control unit is based on the temperature field, flow field and concentration field data provided by the TFC state detection unit, and the NOx concentration and NH concentration at the inlet and outlet of the SCR denitrification system provided by the NOx online monitoring device. 3 SCR denitrification system outlet NH provided by online monitoring system 3 Concentration, as well as the boiler load, burner operation status, and flue gas volume data provided by the boiler working condition online monitoring system, are calculated, and the calculated injection concentration and injection volume of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com