Solid waste harmless and resourceful treatment method and treatment device

A technology of solid waste and treatment method is applied in the field of solid waste harmless and resourceful treatment methods and treatment devices to achieve the effect of convenient fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

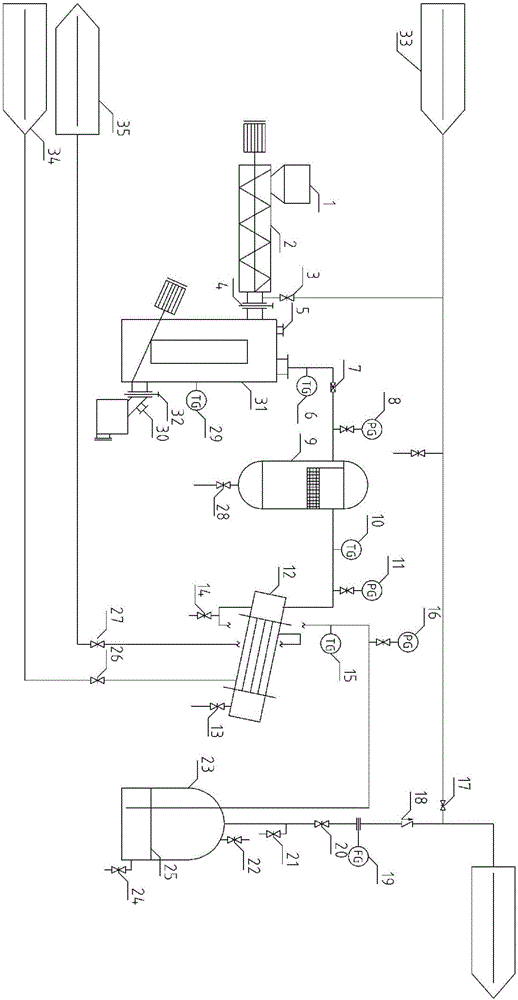

Method used

Image

Examples

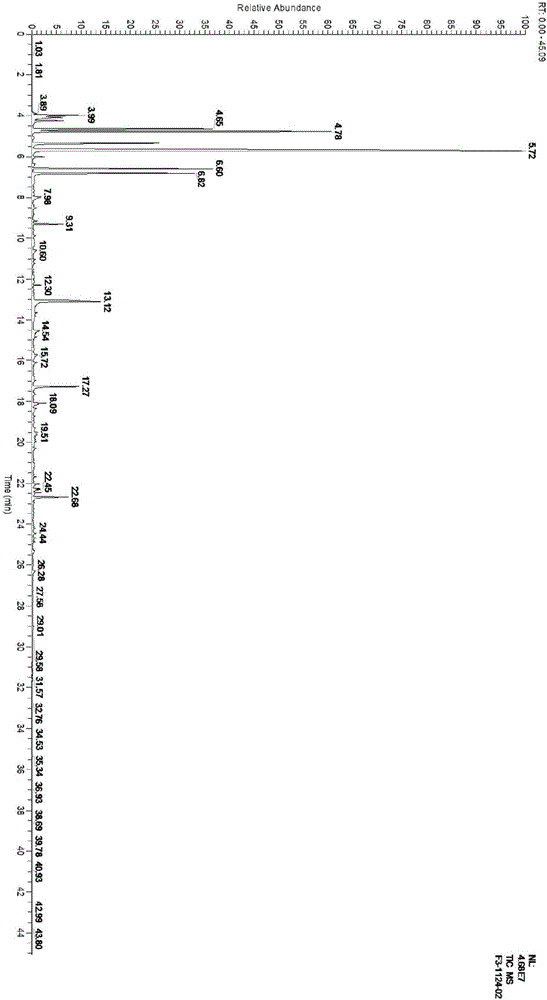

Embodiment 1

[0038]The garbage is selected from the garbage sieve of Beijing Fengtai landfill. Experimental data show that cracking 1 ton of Fengtai garbage oversize can yield 28% cracking gas, 51% cracking liquid product and 19% solid. The analytical data and calorific value test data of the pyrolysis products are shown in attached tables 1-2. The power consumption for cracking 1 ton of Fengtai garbage sieve is 580 degrees, and 280 kg of combustible gas, 510 kg of liquid fuel oil and 210 kg of solid residue can be obtained. The calorific value of gas products from cracking Fengtai garbage is 10200kcal / kg, which is similar to the calorific value of natural gas, and can be calculated based on the power generation capacity of natural gas at 4.5 kcal / kg. The power generation capacity of 280 kilograms of cracked gas products is 1260 degrees. The calorific value of the liquid product of photocatalytic cracking Fengtai garbage is 10500kcal / kg, which can be calculated as 3.8 degrees / kg, and the...

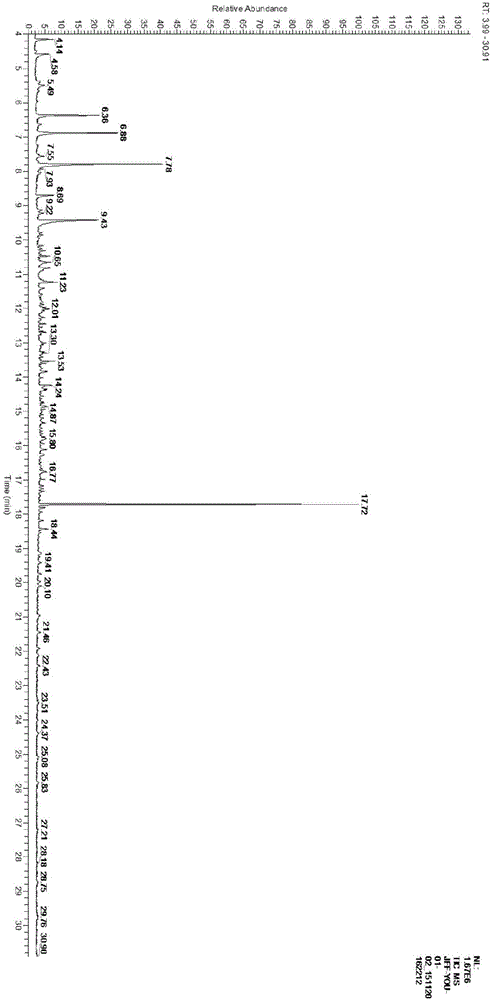

Embodiment 2

[0040] The waste is Zhengzhou medical waste. Experimental data shows that 35% of cracked gas, 57% of cracked liquid product and 8% of solid can be obtained by cracking 1 ton of medical waste. The analytical data and calorific value test data of the pyrolysis products are shown in attached tables 3-4. It consumes 612 degrees of electricity to crack a ton of medical waste, and can obtain 350 kg of combustible gas, 570 kg of liquid fuel oil, and 80 kg of solid residue. Calculated on the basis of gas-fired power generation capacity of 4.2 kWh / kg, the power generation capacity of 350 kg of cracked gas products is 1470 kWh. The power generation of liquid products is calculated at 3.8 kWh / kg, and the power generation of 570 kg of photocatalytic cracking liquid products is 2166 kWh. The total power generated by the gas-liquid products is 3636 kWh, minus the total power consumption of 612 kWh for cracking, the actual power generation is 3024 kWh.

Embodiment 3

[0042] Garbage is selected from crop corn stalks. Experimental data show that cracking 1 ton of corn stalks can yield 45% cracked gas, 35% cracked liquid products and 25% solids. The analytical data and calorific value test data of the pyrolysis products are shown in attached tables 5-6. The power consumption of cracking one ton of corn stalks is 360 degrees, and 400 kg of combustible gas, 350 kg of liquid fuel oil, and 250 kg of solid activated carbon can be obtained. Calculated on the basis of 4.0 degrees / kg of gas-fired power generation, the power generation of 400 kg of cracked gas products is 1600 degrees. The water content of biomass liquid products is relatively large, accounting for about 60%, and must be extracted and separated before generating electricity. Organic matter accounts for 40% of the liquid product, about 140 kg, and its calorific value is greater than 9500Kcal / kg. The power generation of organic matter is calculated at 3.5 degrees / kg, and the power ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Electricity | aaaaa | aaaaa |

| Electricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com