Multi-layer flux-free material with stepped silicon content and its preparation method and application

A silicon content, flux-free technology, which is applied in the field of multi-layer aluminum alloy flux-free materials for heat transmission, can solve the problems of unfavorable welding, unfulfilled external welding, and unfulfilled, etc., and achieve the effect of optimizing the brazing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11, comparative Embodiment 1

[0061] Preparation:

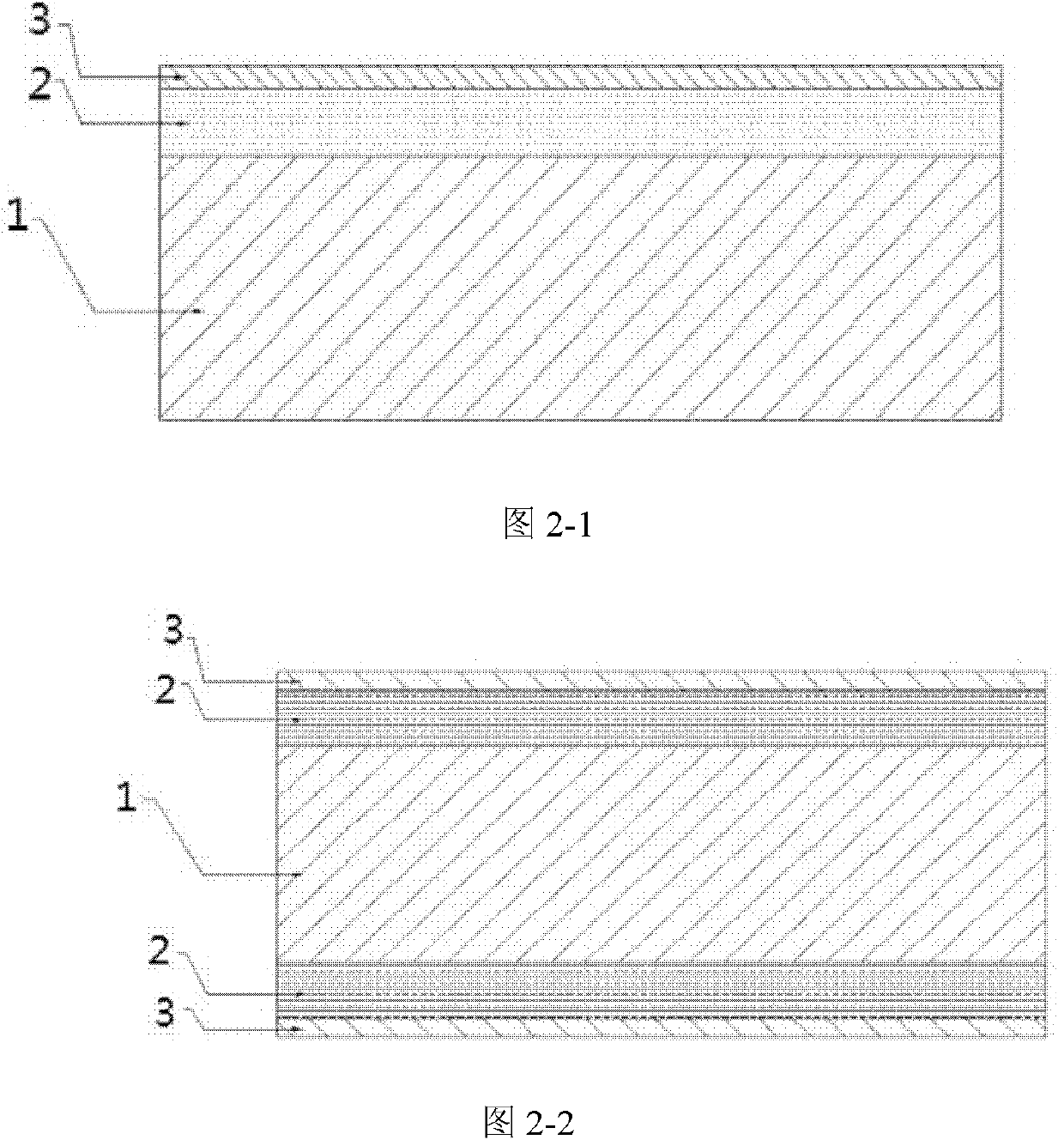

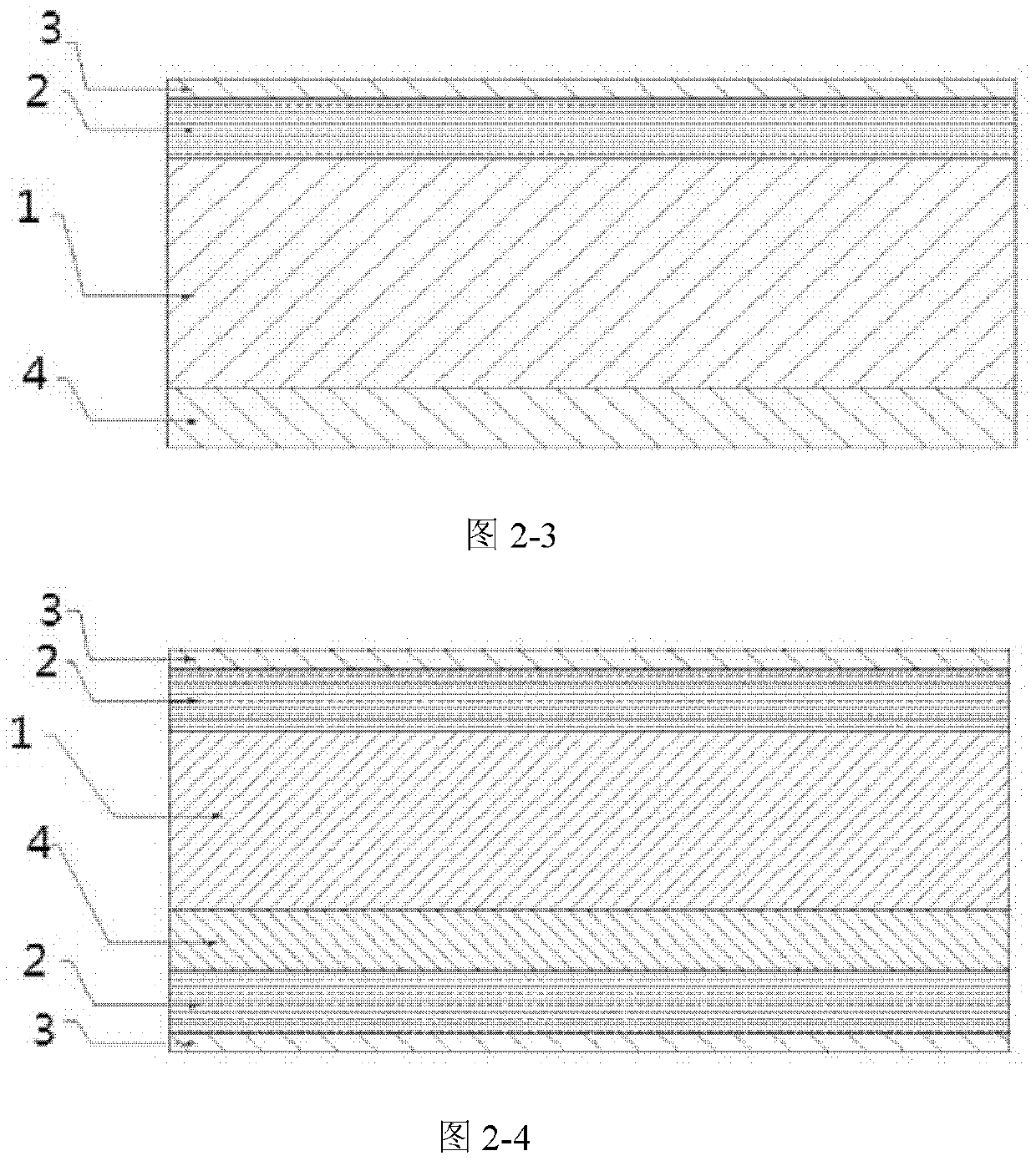

[0062] Alloy casting equipment is used to cast ingots. The length of the cast alloy is 300mm, the width is 200mm, and the thickness is 30mm. The chemical composition of the alloy is shown in Table 1. After face milling, the ingot length is 200mm, width is 150mm, and thickness is 20mm. The core layer, brazing layer, covering layer, and sacrificial layer are homogenized at 500°C. Annealing for 2 hours, then hot rolling, the brazing layer is rolled to 3mm, and the covering layer is rolled to 1mm, and then the six layers of covering layer-brazing layer-core layer-sacrificial layer-brazing layer-covering layer are welded together, and then hot-rolled , rolled to a thickness of 3mm, then cold-rolled, cold-rolled to 0.3mm, and then processed or annealed to different states such as H24 and H14 according to different requirements, and then simulated brazing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com