Wall climbing robot for external wall corners

An exterior corner and robot technology, applied in the field of wall climbing robots, can solve the problems of low energy utilization rate, insufficient load capacity, high material and equipment requirements, and achieve good application prospects and market demand, low power, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the drawings and embodiments.

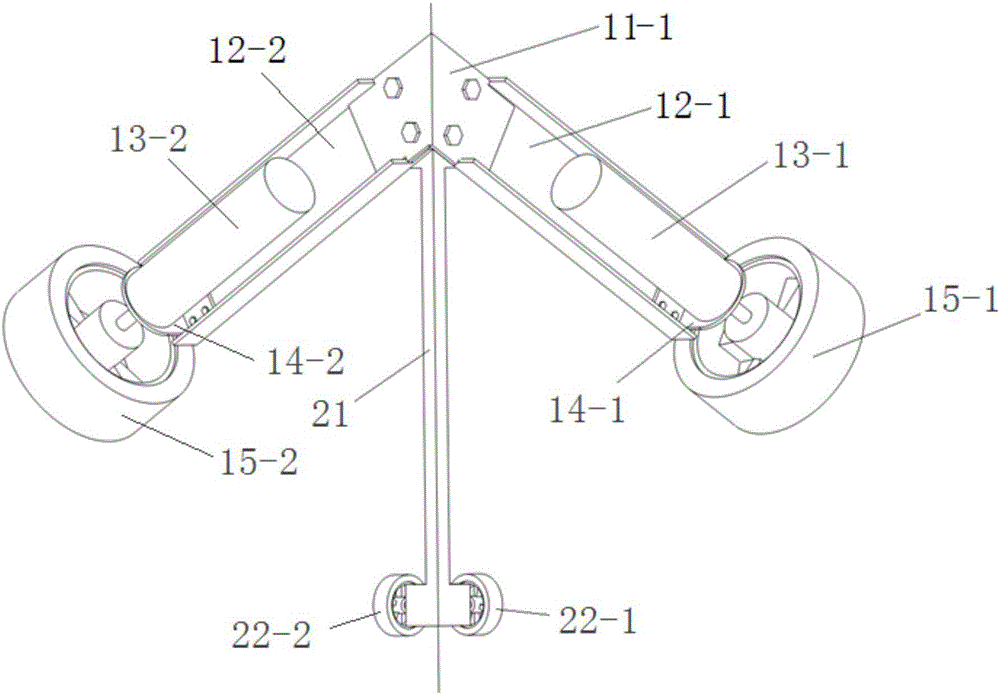

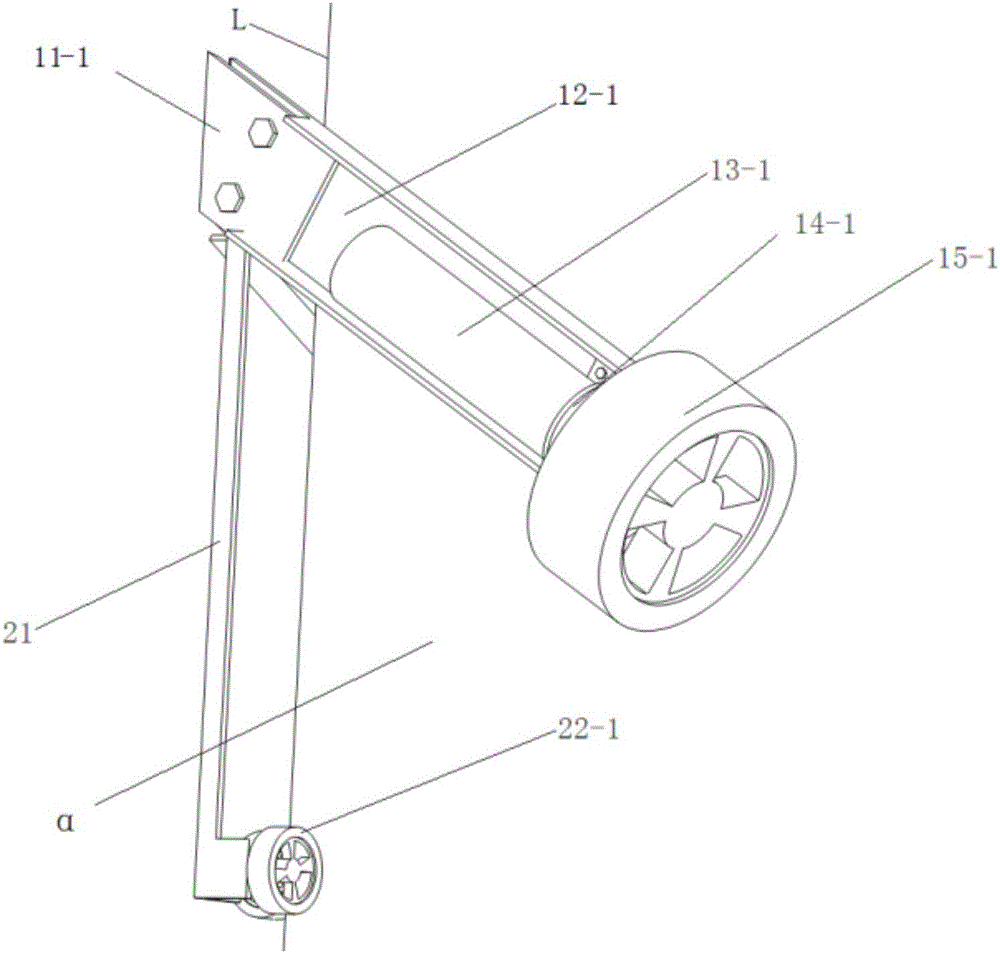

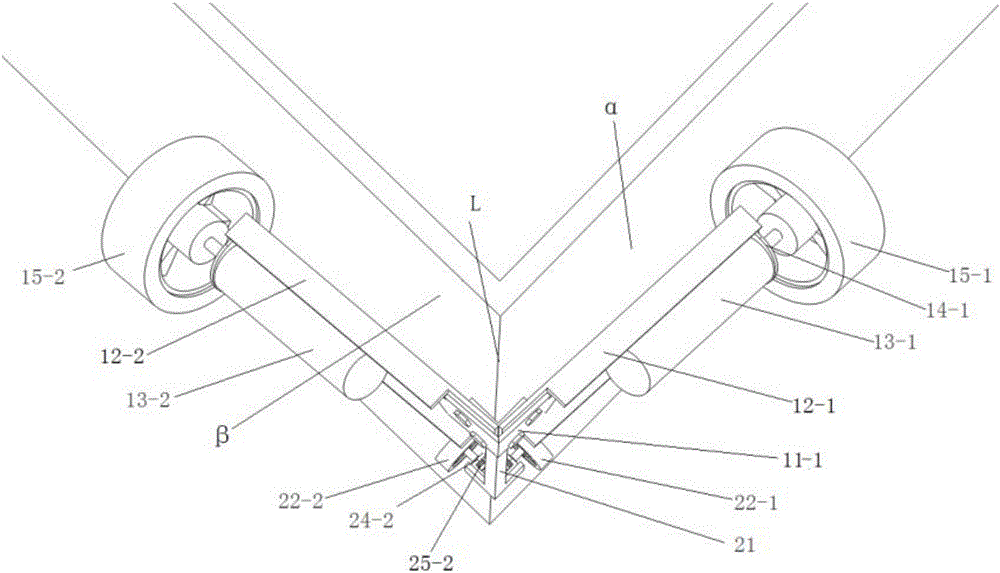

[0023] The invention discloses a wall-climbing robot for exterior wall corners, which is mainly divided into a fuselage part and a tail part. For the fuselage, it is mainly composed of drive wheels, motors, motor tripods, brackets and fixed plates. Such as Figure 1 to Figure 3 As shown, the fixing plate 11-1 is directly opposite to the external corner line L, the left side of the fixing plate 11-1 is connected to a bracket 12-2, and the right side of the fixing plate 11-1 is connected to a bracket 12-1. A motor tripod 14-1 is fixed on 12-1, a motor tripod 14-2 is fixed on 12-2, a motor 13-1 is installed on the motor tripod 14-1, and a motor tripod 14-2 is installed A motor 13-2, the output shaft of the motor 13-1 is connected to a driving wheel 15-1, the output shaft of the motor 13-2 is connected to a driving wheel 15-2, the driving wheel 15-1 is tangent to the wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com