Method for achieving 2H-to-1T phase transition of molybdenum disulfide

A technology of molybdenum disulfide and phase transformation, which is applied in the production of molybdenum sulfide and bulk chemicals to achieve the effect of simple process and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for realizing molybdenum disulfide 2H to 1T phase transformation, the steps are as follows:

[0026] 1) Add 50 mg of molybdenum disulfide into a beaker filled with 10 mL of solvent (deionized water: ethanol = 1:1), and seal it with plastic wrap. The sealed beaker was placed in a water-bath ultrasonic cleaner for 7 hours, then centrifuged at 5000 r / min for 20 minutes, and the upper layer was taken;

[0027] 2) Add 200 mg of PVP surfactant to the supernatant, and sonicate for 0.5h. Transfer to a supercritical reactor, and after reaching supercritical conditions (40°C, 16 MPa), stir continuously for 6 hours; take out the solution, add ethanol aqueous solution (equal ratio of ethanol to water) and centrifuge at a high speed (20000r / min, 20min), repeat three times , and then remove the surfactant; after washing, take away the upper layer, keep the lower precipitate, add solvent to dissolve, and ultrasonically homogenize to obtain MoS 2 solution.

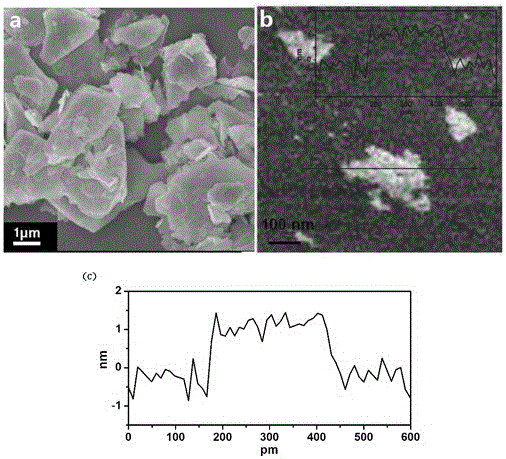

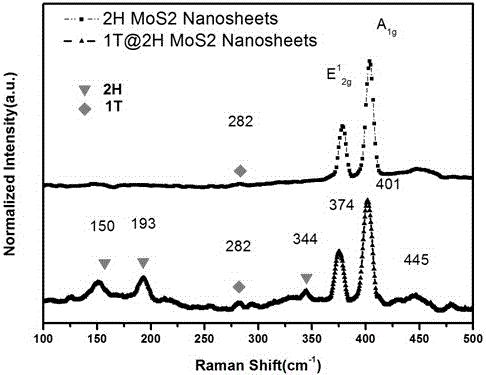

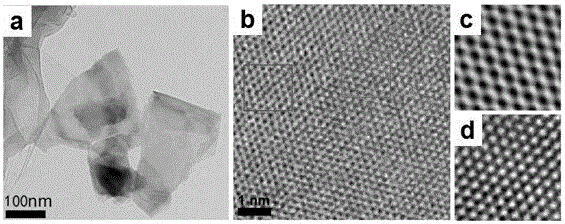

[0028] figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com