Method for preparing hydrophobic SiO2 anti-reflecting film from dodecyl triethoxysilane

A technology of dodecyltriethoxysilane and antireflection film, which is applied in the field of preparing hydrophobic SiO2 antireflection film, can solve the problems such as the decrease of optical performance of the antireflection film, and improve the hydrophobicity and optical stability. Simple and efficient, the effect of improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Preparation of hybrid sol: Mix ethyl orthosilicate, dodecyltriethoxysilane, absolute ethanol and ammonia water into a closed glass container at a mass ratio of 14.2:1.88:130:3.6, Stir at 25°C for 12 h, then age at 20°C for 30 days.

[0018] (2) At an ambient humidity of 20%, the dipping-pulling method is used to coat the cleaned substrate at a certain pulling speed, and the obtained film layer is hydrophobic SiO 2 Anti-reflection coating, the pulling speed of the coating is 100 mm / min.

Embodiment 2

[0020] (1) Preparation of hybrid sol: Mix ethyl orthosilicate, dodecyltriethoxysilane, absolute ethanol and ammonia water in a closed glass container at a mass ratio of 13:3.45:130:3.6, Stir at 30°C for 2 h, then age at 25°C for 6 days.

[0021] (2) At an ambient humidity of 20%, the dipping-pulling method is used to coat the cleaned substrate at a certain pulling speed, and the obtained film layer is hydrophobic SiO 2 Anti-reflection coating, the pulling speed of the coating is 150 mm / min.

Embodiment 3

[0023] (1) Preparation of hybrid sol: Mix ethyl orthosilicate, dodecyltriethoxysilane, absolute ethanol and ammonia water into a closed glass container at a mass ratio of 11.12:5.92:130:3.6, Stir at 50°C for 0.5 h, then age at 40°C for 3 days.

[0024] (2) At an ambient humidity of 20%, the dipping-pulling method is used to coat the cleaned substrate at a certain pulling speed, and the obtained film layer is hydrophobic SiO 2 Anti-reflection coating, the pulling speed of the coating is 200 mm / min.

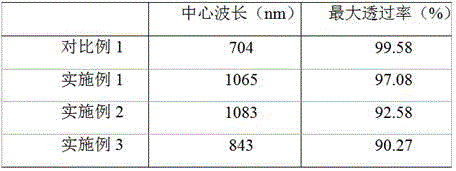

[0025] Table 1 Example SiO 2 Central wavelength and maximum transmittance of AR coating

[0026]

[0027] It can be seen from Table 1 that as the content of dodecyltriethoxysilane increases, the transmittance of the film does not increase, and when the content is 1.88, it still plays an anti-reflection effect.

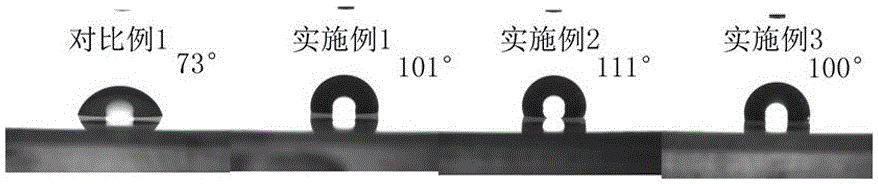

[0028] from figure 1 It can be found that the contact angle of the unmodified AR coating is 73°. However, SiO was hybridized with dodecyltriethoxysilane and ethyl o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com