Modified and activated phosphorus slag, preparation method and modified and activated phosphorus slag cement and concrete

A technology of activating phosphorus and modification, which is applied in the fields of preparation, modification and activation of phosphorus slag, modified and activated phosphorus slag cement and concrete, and can solve the hidden dangers of cement and concrete volume stability, concrete alkali-aggregate reaction, and the incorporation of exciting materials High volume and other problems, to achieve the effect of shortened coagulation time, easy operation and broad prospects

Active Publication Date: 2017-03-08

CHINA BUILDING MATERIALS ACAD

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the current activation methods pay less attention to cement performance, rheology, drying shrinkage, corrosion resistance and other characteristics; and the use of chemical reagents is not only costly, but also has some shortcomings, such as strong alkali, basic salt and chloride salt activator , it is easy to induce concrete alkali-aggregate reaction, steel corrosion and other phenomena; sulfate activators, calcium oxide and other excitation materials will also bring certain hidden dangers to the volume stability of cement and concrete; in addition, the amount of excitation materials mixed in phosphorus slag is too high , will also have a negative impact on the hydration characteristics of phosphorus slag, such as heat of hydration, impermeability, and later strength growth rate, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 27

[0067] The components (by weight percentage) of the modified activated phosphorous slag concrete in this embodiment are: 10% of the modified activated phosphorous slag in Example 1, and 90% of the concrete base material.

Embodiment 28

[0069] The components (by weight percentage) of the modified activated phosphorus slag concrete in this embodiment are: 30% of the modified activated phosphorus slag in Example 1, and 70% of concrete base material.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

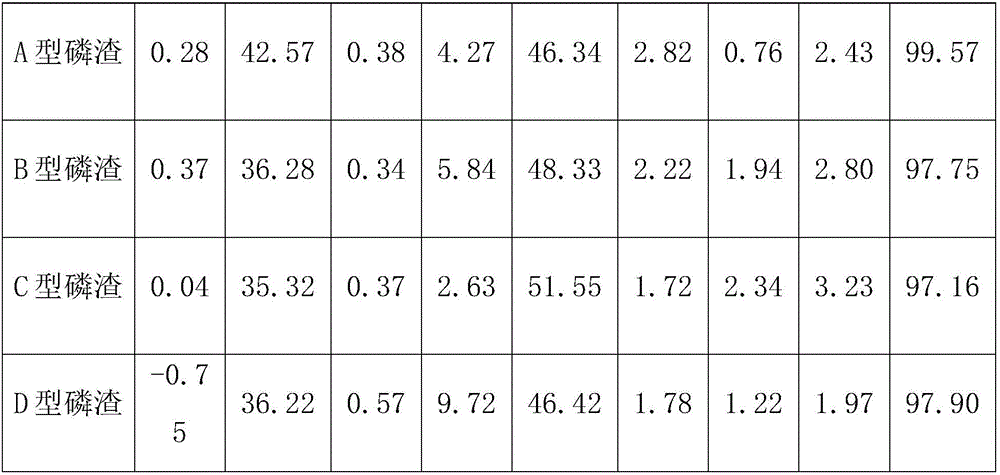

The invention relates to modified and activated phosphorus slag, a preparation method and modified and activated phosphorus slag cement and concrete. The modified and activated phosphorus slag consists of an activating agent and phosphorus slag in mass ratio of (0.5-1):10; the moisture in the phosphorus slag is less than 2% of the weight of the phosphorus slag; and the activating agent consist of the following components in parts by weight: 50-70 parts of carbide slag, 0-40 parts of aluminum sulfate slag, 0-40 parts of red mud, 0-30 parts of high-aluminum fly ash, 20-30 parts of gypsum and 0-30 parts of anhydrous calcium sulphoaluminate mineral. The modified and activated phosphorus slag eliminates the influence of harmful ingredients in the phosphorus slag on the properties of cement and concrete, shortens the cement setting time and improves the cement intensity, and simultaneously improves the intensity of concrete at each age, and the drying shrinkage rate at each age is less than the drying shrinkage rate of slag powder. The activating agents used for modifying and activating the phosphorus slag are various industrial residues and do not contain chemi-excitation reagents, have no adverse effects on the service performance, endurance quality and the like of cement and concrete, enable application of high phosphorus slag content in cement and concrete, and achieve the purpose of changing waste into valuable.

Description

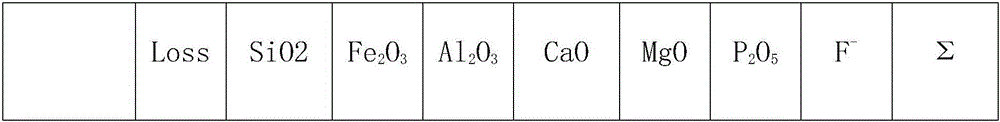

technical field [0001] The invention relates to a modified activated phosphorus slag, in particular to a modified activated phosphorus slag, a preparation method, modified activated phosphorus slag cement and concrete. Background technique [0002] Phosphorus slag is a good reusable resource. Its chemical composition and mineral phase composition are similar to slag. It has good potential hydraulicity, and has the characteristics of good concrete workability, strong impermeability, and large growth rate of strength in the later stage. At present, phosphorus slag has certain applications in cement-based materials, sintered hollow bricks, autoclaved hollow blocks, glass-ceramics, non-burning and non-steaming bricks, pavement base materials, rock wool, etc. However, due to the P in phosphorus slag 2 o 5 Harmful components such as phosphonium and other harmful components have a great influence on the setting and hardening of cement and the development of early strength, so its...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B22/14C04B20/02C04B7/14C04B28/00

CPCC04B7/14C04B20/023C04B28/006C04B40/0039C04B18/04C04B18/0409C04B18/08C04B22/143C04B18/023C04B18/145Y02P40/10

Inventor 王昕颜碧兰刘晨朱文尚杜勇

Owner CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com