Preparation method of microcapsule concrete based on microwave and freeze thawing maintenance

A technology of microcapsules and concrete, which is applied in the field of road pavement materials, can solve the problems of difficulty in ensuring the comprehensive performance of concrete, little improvement in durability performance, and difficulty in concrete performance, and achieve the effect of increasing bonding fastness, increasing strength, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

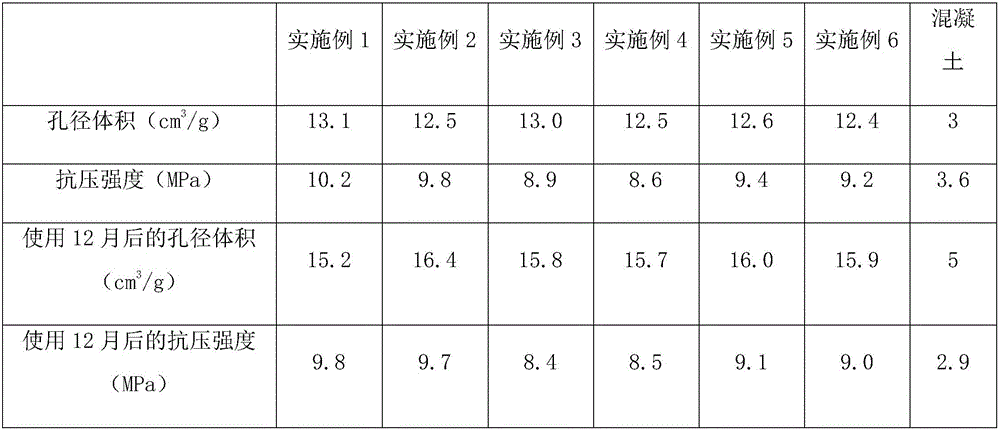

Examples

Embodiment 1

[0027] (1) The epoxy resin microcapsules coated with Bacillus pasteurianus and the epoxy resin microcapsules coated with calcium lactate and urea are added to water at a mass ratio of 3:1, stirred, until dispersed to form a microcapsule solution, wherein The total mass fraction of the epoxy resin microcapsules coated with Bacillus pasteurianus and the epoxy resin microcapsules coated with calcium lactate and urea in the microcapsule solution is 5%.

[0028] (2) Diferric iron tetroxide and iron oxide with a mass ratio of 2:1 are dispersed, pressed, calcined, and pulverized to form an iron-containing auxiliary agent with a particle size of 150 mesh, and silicon dioxide with a particle size of 50 μm, 0.25 mm natural River sand and polypropylene short fiber are mixed at a ratio of 1:0.8:0.5 to form a filler, and Portland cement is added to the water, fully stirred, and then filler, iron-containing additives and NF water reducer are added, fully stirred, and then added The microcap...

Embodiment 2

[0031] (1) The epoxy resin microcapsules coated with Bacillus pasteurianus and the epoxy resin microcapsules coated with calcium lactate and urea are added to water in a mass ratio of 4:1, stirred, and evenly dispersed to form a microcapsule solution, wherein The total mass fraction of epoxy resin microcapsules coated with bacillus pasteuriana and epoxy resin microcapsules coated with calcium lactate and urea in the microcapsule solution is 15%.

[0032] (2) Diferric iron tetroxide and iron oxide with a mass ratio of 2:1.5 are dispersed, pressed, calcined, and pulverized to form an iron-containing additive with a particle size of 200 meshes, and silicon dioxide with a particle size of 100 μm, 0.35 mm natural River sand and polypropylene short fiber are mixed at a ratio of 1:1.2:0.7 to form a filler, and Portland cement is added to the water, fully stirred, and then filler, iron-containing additives and NF water reducer are added, fully stirred, and then added The microcapsule ...

Embodiment 3

[0035] (1) The epoxy resin microcapsules of the coated bacillus pasteurianus and the epoxy resin microcapsules of the coated calcium lactate and urea are added in water at a mass ratio of 3.5:1, stirred, and evenly dispersed to form a microcapsule solution, wherein The total mass fraction of epoxy resin microcapsules coated with bacillus pasteuriana and epoxy resin microcapsules coated with calcium lactate and urea in the microcapsule solution is 10%.

[0036] (2) Diferric iron tetroxide and iron oxide with a mass ratio of 2:1.2 are dispersed, pressed, calcined, and pulverized to form an iron-containing auxiliary agent with a particle size of 180 meshes, and silicon dioxide with a particle size of 80 μm, 0.30 mm natural River sand and polypropylene short fiber are mixed at a ratio of 1:1:0.6 to form a filler. Add Portland cement to the water and stir thoroughly, then add filler, iron-containing additives and NF water reducer, stir fully, and then add The microcapsule solution pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com